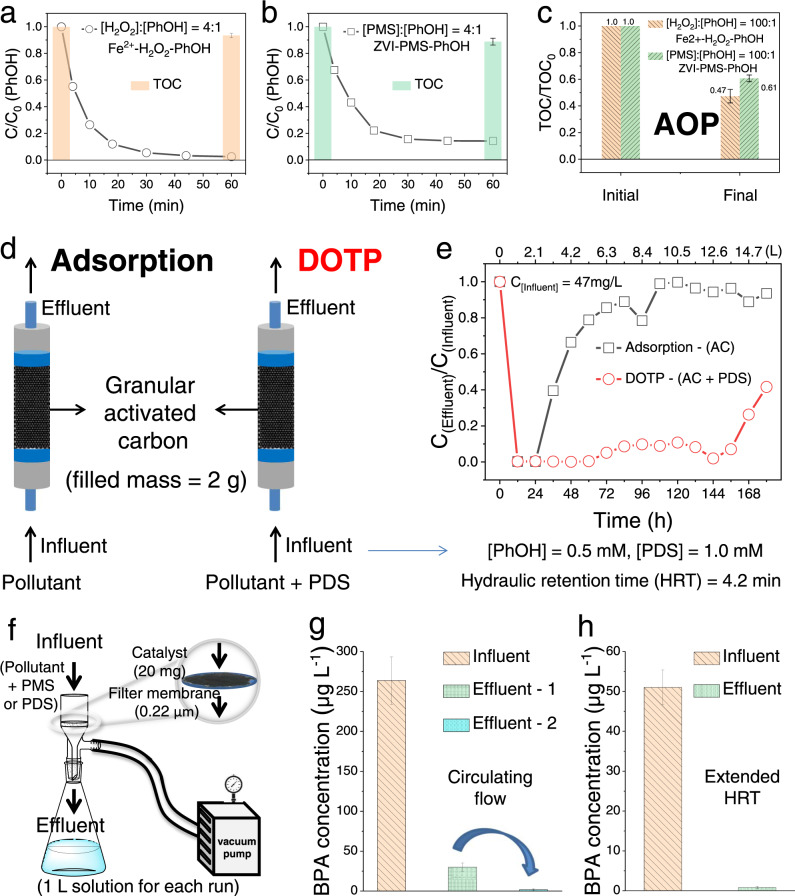

Fig. 7. Evaluation of the practical application of DOTP, AOP, and adsorption processes.

a, b Pollutant removal and TOC elimination in the typical Fe2+/H2O2 (a) and ZVI/PMS (b) AOP systems, with oxidants to pollutants dosage ratios of 4:1. c Final removal of TOC in the two typical AOP systems at an oxidant dosage 100 times the molar concentration of the pollutant. d, e Water purification effects reflected by the continuous-flow operation of DOTP and adsorption illustrated in fixed bed reactor. f Schematic illustration of the membrane catalytic reactor (catalyst mass = 20 mg). g, h Detected BPA concentrations in the influent and effluent for 1-L tap water with an initial BPA concentration approximately at (g) 250 µg L−1 and (h) 50 µg L−1. For g, the first-run effluent (effluent-1) was reflowed over the membrane catalytic reactor for further BPA removal to obtain the second-run effluent (effluent-2). For h, the hydraulic retention time (HRT) was extended from 20 min/L (in g) to 40 min L−1. The circulating flow of the first-run effluent in g and the extension of HRT in h were used for increasing the contact efficiencies between the pollutant/oxidant and the catalyst surface. These two methods were both effective to reduce the influence of diffusion control of micropollutants at low concentrations and thus increase their removal efficiency. ZVI zero-valent iron, AC activated carbon.