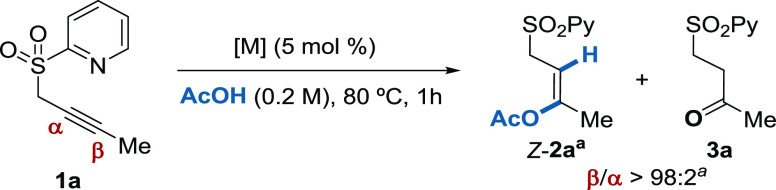

Table 1. Optimization Studies for the Acetoxylation of Substrate 1a.

| entry | catalyst | Z-2a/3aa | yield (%)b |

|---|---|---|---|

| 1 | Pd(OAc)2 | >98:2 | 86 |

| 2 | Pt(CH3CN)2Cl2 | 44:56 | 72 |

| 3 | AuCl(PPh3)/AgOTf | 62:38 | 66 |

| 4 | AgSbF6 | decomp | |

| 5 | Zn(ClO4)2·6H2O | nr | |

| 6c | Pd(OAc)2 | >98:2 | 41 |

| 7d | Pd(OAc)2 | >98:2 | 76 |

| 8 | PdBr2 | nr | |

| 9 | Pd(acac)2 | >98:2 | 10 |

| 10 | Pd(TFA)2 | nr | |

| 11 | PdCl2(CH3CN)2 | decomp | |

| 12 | none | nr | |

| 13 | Pd/Aue | 94:6 | 79 |

| 14 | Pd(OAc)2,H2Of | 86:14 | 81 |

| 15 | Pd/Aue,H2Of | 52:48 | 85 |

Determined by 1H NMR spectroscopy from the crude mixture.

Determined by 1H NMR using 1,3,5-trimethoxybenzene as an internal standard.

3 mol % Pd(OAc)2 was used.

Reaction performed at 60 °C during 5 h for full completion.

A combination of Pd(OAc)2 (5 mol %) and AuCl(PPh3)/AgOTf (5 mol %) was used as a catalyst.

Extra water (10% v/v) was added to the reaction mixture. nr: no reaction (starting material recovered).