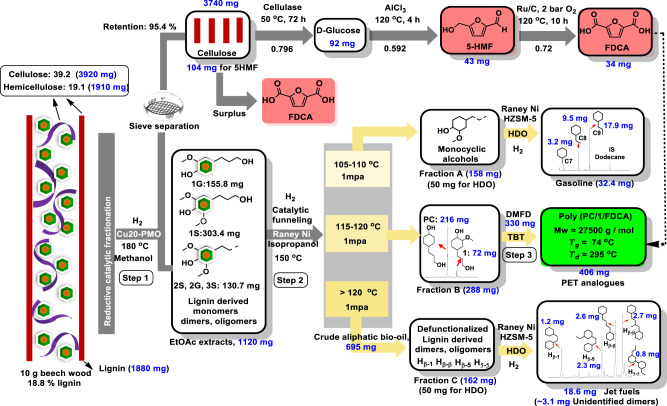

Fig. 5. Comprehensive catalytic protocol for beech wood biorefinery for producing PET analogues and fuels.

Step 1: RCF of beech wood over Cu20-PMO catalyst (10 g beech wood, 2 g Cu20-PMO catalyst, 120 mL methanol, 40 bar H2, 180 °C, 18 h) gives crude lignin oil and residual carbohydrates; Removal of impurities gives EtOAc extracts; Step 2: Catalytic funneling of EtOAc extracts (1120 mg EtOAc extracts, 2 g wet Raney Ni catalyst, 30 mL isopropanol, 150 °C, 12 h) delievers a mixture of crude aliphatic oil which is purified by distillation under 1 mpa at (100 –120 °C) to deliver three Fractions (A (100–105 °C), B (115 – 120 °C) and C (>120 °C)). PET analog synthesis: Reaction conditions (288 mg Fraction B, 330 mg DMFD (1.79 mmol), 1 mol% TBT catalyst, 190 °C N2 for 1 h, 230 °C under vacuum for 3 h), Copolymerization of Fraction C with DMFD yields poly (PC/1/FDCA); Hydrodeoxygenation: Reaction conditions (50 mg Fraction A or C, 200 mg wet Raney Ni, 100 mg activated HZSM-5 co-catalyst, 20 mL cyclohexanol, 220 °C, 30 bar H2, 4-6 h); HDO of Fraction A gives C7, C8, and C9 cyclic alkanes. HDO of Fraction C gives high-density cyclic alkanes. The hydrocarbons were quantified using the response of the flame-ionization detector (FID) and the response factors were estimated by the effective carbon number method (ECN).