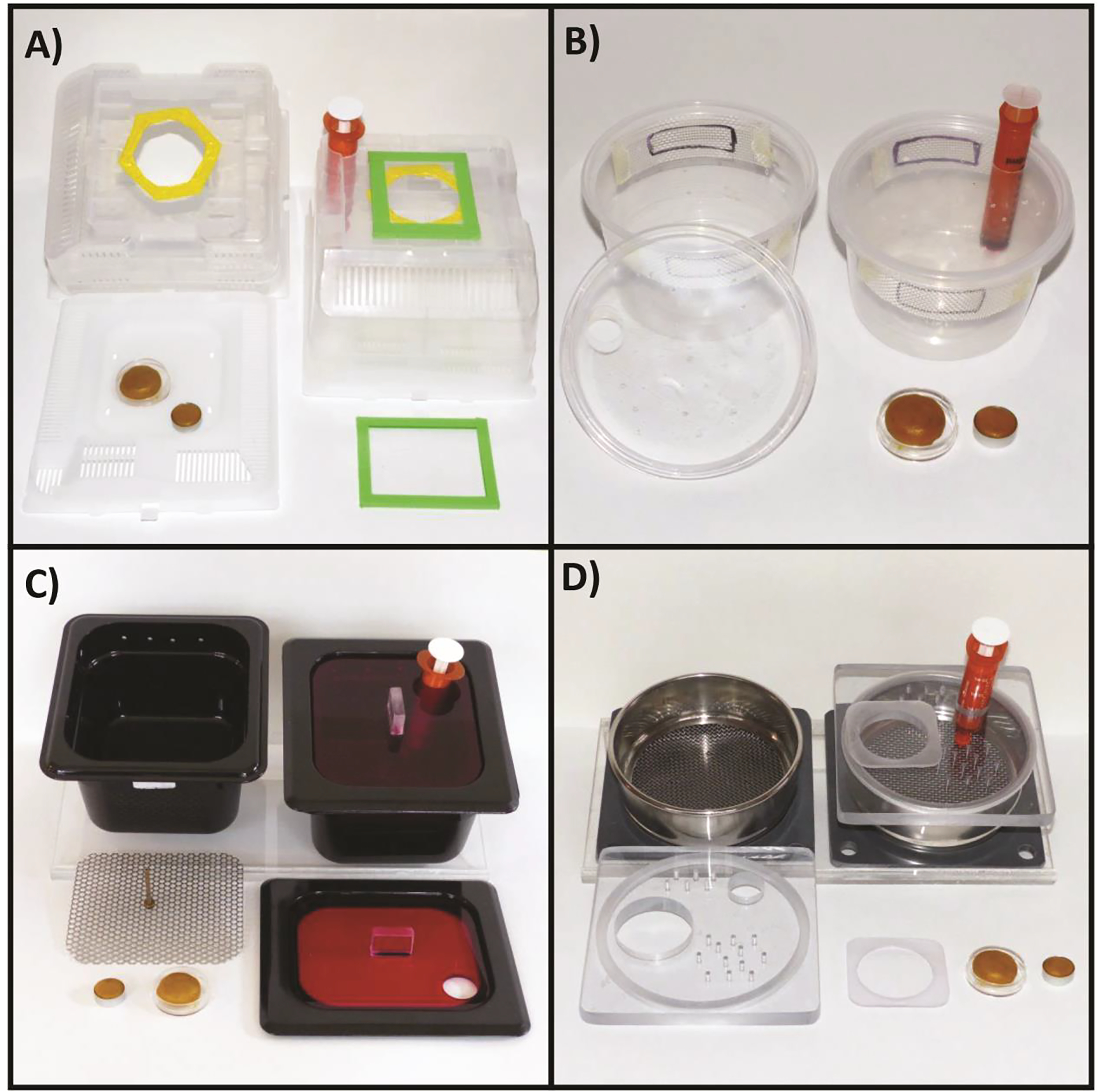

Figure 4. Example microcolony chambers.

A) “Queen box” (17.8 × 15.2 × 10.1 cm) used by commercial bumble bee vendors (i.e., Koppert, Biobest) with syringe feeder (USDA-ARS Pollinating Insect Research Unit; North Logan, UT). B) Disposable “deli cup” (16 oz, 11.4 cm tall × 7.6 cm diameter) modified with mesh to improve ventilation and to accommodate a syringe feeder (USDA-ARS Pollinating Insect Research Unit; North Logan, UT). C) Food pan (1/4 size, 12.7 × 11.4 × 10.1 cm) modified to include a raised perforated stainless-steel mesh floor to separate bee waste from the nest area, see-through red plexiglass lid, syringe feeder and holes for additional ventilation (US EPA, RTP, NC). D) Stainless steel geology sieve (4 cm tall × 12.7 cm diameter) with pass-through floor, ventilated baseplate, see-through lid and syringe feeder (US EPA, RTP, NC; design adopted from Bayer CropSciences). All container designs are shown with petri dish containing a pollen ball for nest initiation and a separate dish for pollen feeding.