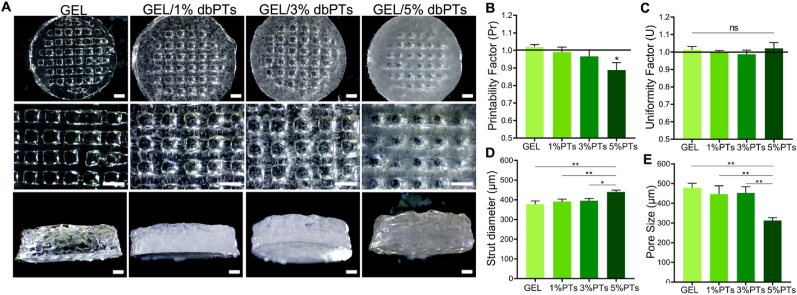

Fig. 3.

3D-printed GEL, GEL/1%dbPTs, GEL/3%dbPTs, and GEL/5%dbPTs composite scaffolds. (A) Light microscopy images of the 3D GEL/dbPTs scaffolds in top and side view after crosslinking. Scale bars: 1000 μm. (B–E) Printability assessments of the GEL/dbPTs scaffolds (n = 4), (B) Printability factor (Pr), (C) Uniformity factor (U), (D) strut diameter, and (E) pore size of the scaffolds. Data are shown as mean ± SD. ∗p < 0.05 and ∗∗p < 0.01 indicate statistically significant difference of means in comparison to 3D-printed GEL by one-way ANOVA tests.