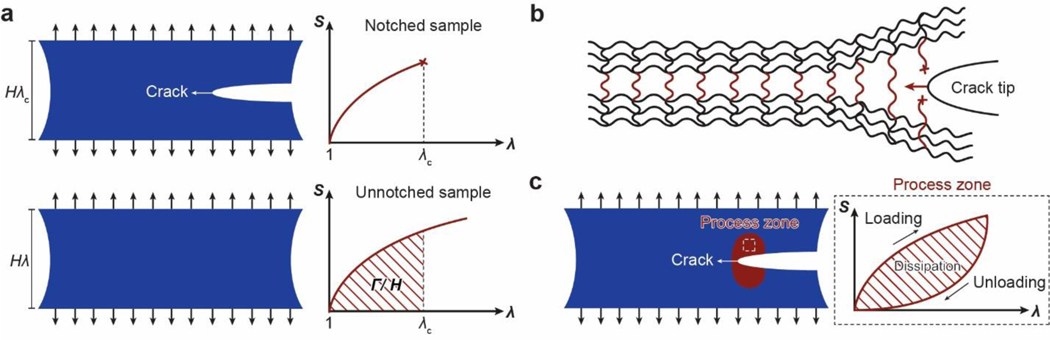

Figure 11. Design principle for tough hydrogels – build dissipation into stretchy polymer networks.

a. definition of fracture toughness and the pure-shear test to measure the fracture toughness. When a notched sample with height H at the undeformed state is stretched by a critical ratio of λc under pure-shear deformation, the crack begins to propagates (top). The relation of the nominal stress s and the stretch λ is measured for an un-notched sample (otherwise the same as the notched sample) under pure-shear deformation (bottom). The fracture toughness can be calculated as based on the measured λc and s vs λ relation in the pure-shear tests. b. the intrinsic fracture energy from fracturing a layer of polymer chains. c. the mechanical dissipation in the process zone around the crack tip dramatically contributes to the fracture toughness by . The mechanical dissipation manifests as a hysteresis loop on the stress-stretch curve. The total fracture toughness of the tough hydrogel is .