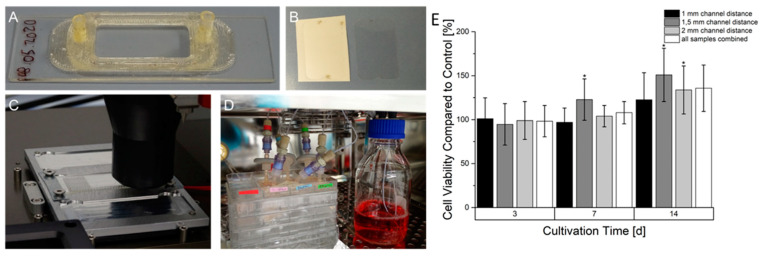

Figure 8.

Manufacturing process, set up and resazurin conversion of HepG2 in prevascularized constructs after continuous cultivation. (A): 3D printed miniaturized bioreactor made of COC printed on a COC slide. (B): Laser structured adhesive foil on carrier foil (left) and after removal from carrier foil (right). (C): Printing process of the bioreactor on a heated aluminum-based slide carrier. (D): Set-up of bioreactors in the incubator connected to the fluidic system. (E): Time-dependent cell viability of continuously cultured prevascularized HepG2-laden constructs. The cell viability at every time point is normalized to an equivalent statically cultured construct serving as a control. Graphs marked with * show a statistical significance compared to their statically cultured equivalent (significance level: * p > 0.005 n = 6).