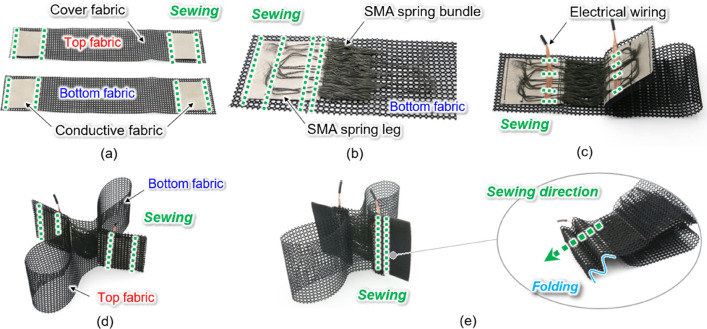

Figure 3.

Fabric muscle fabrication process. (a) To electrically connect the SMA springs, the conductive fabric (50 mm 50 mm) is sewn (green dotted lines) and fixed to the cover fabric (both top and bottom fabrics, width 60 mm, height 300 mm). (b) 200 SMA springs are aligned on the cover fabric (bottom fabric). SMA spring legs are arranged above and below the conductive fabric and sewn fixed so that electricity can flow to the SMA springs. (c) Electrical wires are arranged above and below the conductive fabric and sewn fixed to supply external power to the SMA springs. (d) Cover fabrics (both top and bottom) are overlapped so that the conductive fabrics align and then sewn. (e) Conductive fabric part with the SMA spring legs fixed is folded twice and fixed with sewing.