Table 3.

Different spinning processes for producing lignocellulosic biomass-based CFs.

| Carbon Fiber Precursor | Spinning Process | Set-Up | Property | Advantage | Refs |

|---|---|---|---|---|---|

| lignin (25 wt%)/PAN | Wet-spinning |

|

Tensile strength of 2.25 GPa Modulus of 217 GPa |

Reduced fiber porosity | [155] |

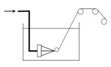

| Acetylated softwood kraft lignin | Dry-spinning |

|

Tensile strength of 1.06 ± 0.07 GPa Modulus of 52 ± 2 GPa |

Enhanced carbon layer plane orientation of the fibers | [17,46] |

| Modified hardwood kraft lignin | Melt-spinning |

|

Tensile strength of 1.07 GPa | Improved mechanical properties | [76] |

| Lignin–cellulose acetate blends | Electrospinning |

|

Tensile strength of 49 ± 4 MPa Modulus of 3.0 ± 0.5 GPa |

A large molecular weight, uniform molecular weight distribution, excellent thermal stability, and good spinnability of the PFs |

[89] |