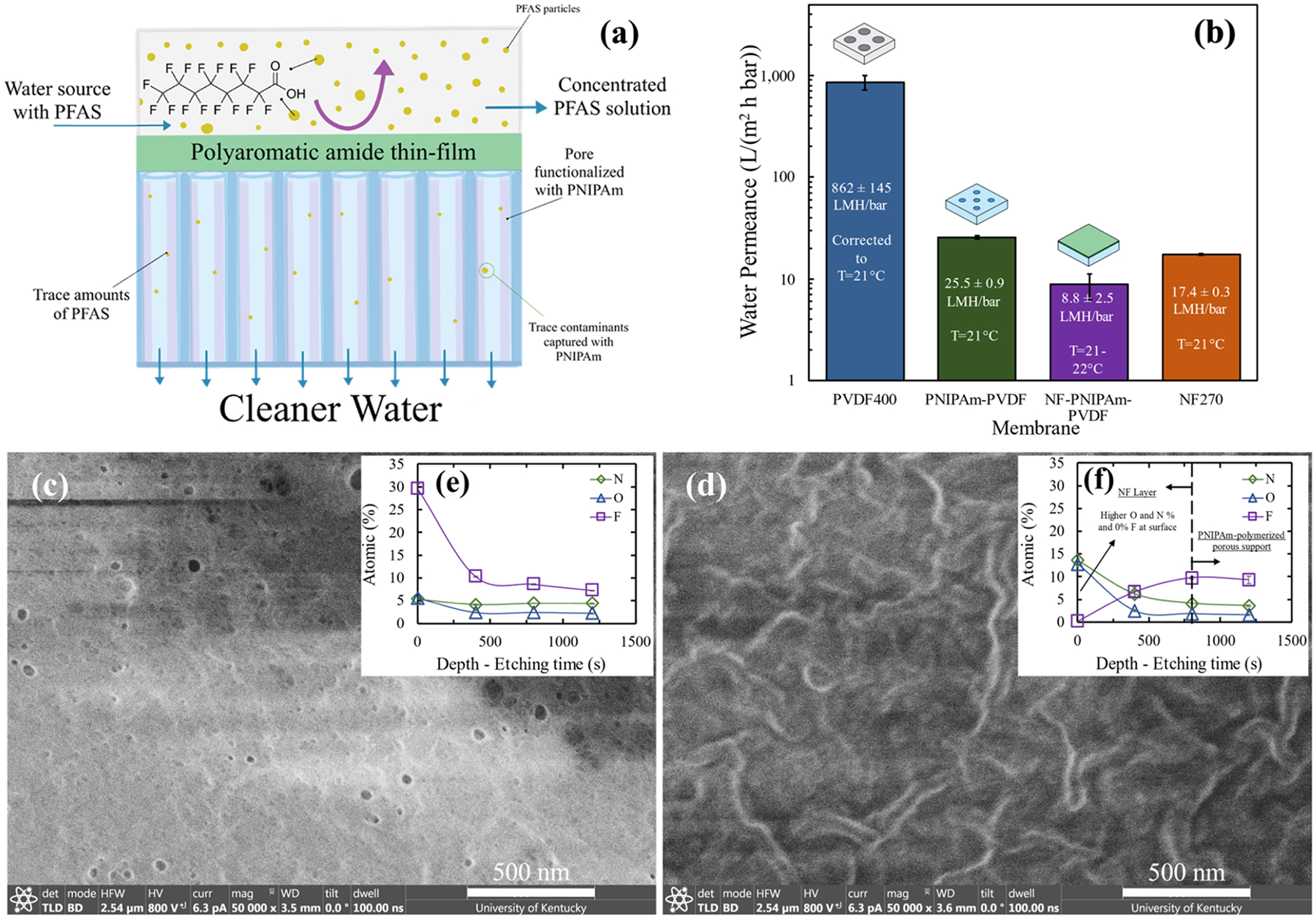

Figure 4.

(a) Diagram illustrating the developed material and its separation mechanisms (exclusion and adsorption) toward PFAS separation. (b) Water permeability coefficient (A) or also called water permeance (thickness-dependent) of the commercial PVDF400, PNIPAm-PVDF (weight gain 14.8%), and NF-PNIPAm-PVDF membranes (PNIPAm weight gain 10.0–11.7%) was calculated from the equation Jw = A·(ΔP). Data for NF270 was included for comparison. The permeability was measured over a pressure range of 1.4–4.0 bar for the PVDF400 membrane, 1.9–9.2 bar for the PNIPAm-PVDF and NF270 membranes, and 2.0–9.6 bar for the NF-PNIPAm-PVDF membrane. Crossflow systems were used for these measurements. For the membrane containing functional materials and the NF270 membrane, the measurements were taken at 21–22 °C; PVDF400 measurements were taken at 26 °C and adjusted to 21 °C using viscosity corrections. (c, d) SEM of the surface transformation from the (c) pore-functionalized material to the formation of the (d) thin-film polyamide. (e, f) XPS depth profiles of the respective materials from each SEM image to corroborate PNIPAm and polyamide addition. Carbon accounts for the remaining percent.