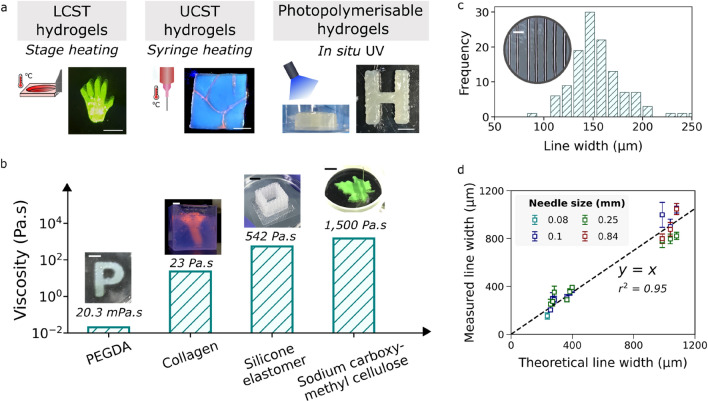

Figure 2.

(a) Figure showing the use of different auxiliary tools for assisting the printing of LCST hydrogels (e.g. Pluronic F127), UCST hydrogels (e.g. gelatin), and photopolymerizable hydrogels (e.g. methacrylate hydroxypropyl cellulose). (b) A wide variety of materials over a large viscosity range can be printed using the setup. (c) Distribution of the line width of the printed Pluronic F127 filaments fabricated using a 34G needle, an extrusion flow of 825 μL/h and a stage speed of 5 mm/s. Median line width = ~ 150 μm. (n = 120 measurements over 4 independent samples). (d) Figure comparing the theoretical line width and the measured line width (n ≥ 20) obtained when different print parameters were used (i.e. stage speed, extrusion flow and needle size). The experiments were performed with Pluronic F127 at over-extrusion condition, where theoretical line width resulting from the printing setting is larger than the needle size. The deviation of the points from the identity line (y = x, shown as black line) indicates the discrepancy between the measured and the theoretical line widths. Scale bars in (a) and (b) = 5 mm. Scale bar in (c) = 500 µm.