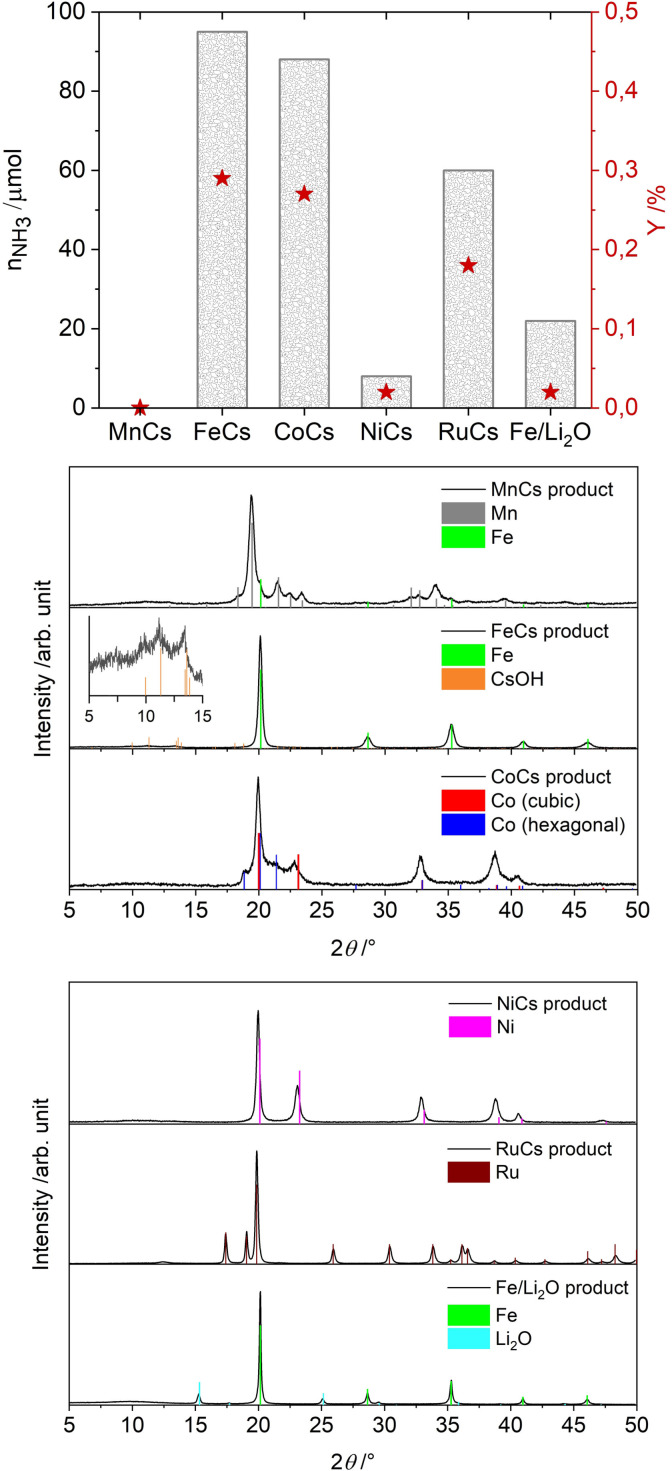

Figure 1.

Results for selected batch systems. (top) Molar amount of ammonia in the gas phase and yields based on nitrogen for metals promoted by cesium or lithium oxide. Reaction conditions were: 48 repetitions of 30 min each with a pause of 5 min in between each run, 500 revolutions‐per‐minute (rpm), three 10 mm and three 15 mm steel balls were used, Fritsch Pulverisette 6. The jar was loaded with 2.0 g of material. For the systems promoted by cesium, 1.9 g of d‐metal and 0.1 g of cesium were used and the reactions were conducted at 50 bar (H2:N2, 3:1). For the reaction with iron and lithium oxide, 1.0 g of each compound was used and the milling was performed at 170 bar (H2:N2, 3:1). (middle and bottom) PXRDs of the resulting products after milling. For the MnCs reaction, additional Fe reflections from abrasion are visible and for the FeCs reaction, extremely weak reflections of CsOH were detected. For the NiCs product, the reflections of Ni are slightly shifted, possibly due to abrasion of iron and subsequent alloying.