Table 1.

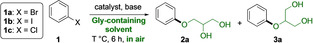

Optimization of Ullmann‐type C−O bond formation between halobenzene 1 and Gly of the corresponding eutectic mixture to give adducts 2 a and 3 a.[a]

|

| ||||||

|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

Entry |

Solvent |

Catalyst (mol %) |

Base (equiv.) |

T [°C] |

2a+3a yield[b] [%] |

2a/3a [c] |

|

1 |

ChCl/Gly[d] |

CuI (10) |

K2CO3 (2) |

60 |

–[e] |

– |

|

2 |

ChCl/Gly[d] |

CuI (10) |

K2CO3 (2) |

80 |

98 |

77 : 23 |

|

3 |

ChCl/Gly[d] |

CuI (5) |

K2CO3 (1) |

80 |

98 |

80 : 20 |

|

4 |

ChCl/Gly[f] |

CuI (5) |

K2CO3 (1) |

80 |

98 |

80 : 20 |

|

5 |

ChCl/Gly[g] |

CuI (5) |

K2CO3 (1) |

100 |

30[e] |

80 : 20 |

|

6 |

ChCl/Gly[d] |

CuI (5) |

– |

80 |

NR[h] |

– |

|

7 |

ChCl/Gly[d] |

– |

K2CO3 (1) |

100 |

NR[h] |

– |

|

8 |

ChCl/Gly[d] |

CuI (5) |

Cs2CO3 (1) |

80 |

98 |

78 : 22 |

|

9 |

ChCl/Gly[d] |

CuI (5) |

tBuOK (1) |

80 |

98 |

77 : 23 |

|

10 |

ChCl/Gly[d] |

CuO (5) |

K2CO3 (1) |

80 |

90 |

78 : 22 |

|

11 |

ChCl/Gly[d] |

CuCl2 (5) |

K2CO3 (1) |

80 |

98 |

80 : 20 |

|

12 |

ChCl/Gly[d] |

Pd(OAc)2 (5) |

K2CO3 (1) |

100 |

–[i] |

– |

|

13 |

Gly |

CuI (5) |

K2CO3 (1) |

100 |

75 |

76 : 24 |

|

14 |

ChCl/Gly[j] |

CuI (5) |

K2CO3 (1) |

80 |

96 |

80 : 20 |

|

15 |

ChCl/Gly[k] |

CuI (5) |

K2CO3 (1) |

80 |

98 |

80 : 20 |

|

16 |

Pro/Gly |

CuI (5) |

K2CO3 (1) |

100 |

– |

– |

|

17 |

betaine/Gly |

CuI (5) |

K2CO3 (1) |

100 |

20[l] |

78 : 22 |

[a] Reaction conditions: 1.0 g DES or 1 mL Gly per 1.0 mmol of 1 a–c; DES: ChCl/Gly (1 : 2, 1 : 1, or 1 : 3 mol mol−1); l‐proline (Pro)/Gly (2 : 5 mol mol−1); betaine/Gly (1 : 2 mol mol−1). [b] The yields reported are for products isolated and purified by column chromatography. [c] Calculated by 1H NMR spectroscopy of the crude reaction mixture using an internal standard technique (NMR internal standard: CH2Br2). [d] X=Br. [e] Reaction time: 24 h. [f] X=I. [g] X=Cl. [h] NR=no reaction. [i] Biphenyl was the only adduct isolated (98 % yield). [j] 1 : 1 mol mol−1. [k] 1 : 3 mol mol−1. [l] After 24 h: 55 % yield.