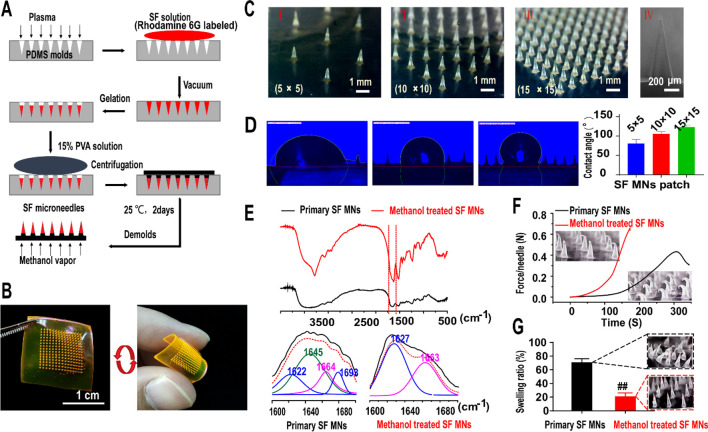

Figure 1.

Fabrication and characterization of silk fibroin microneedle patches. (A) Manufacturing process of silk fibroin microneedle patches (SF MNs). (B) Array of 15 × 15 silk fibroin microneedle patch with a soft backing layer, labeled with rhodamine 6G. Scale bar, 1 cm. (C) Digital photograph of three different arrays of SF MN patches (I, II, III) with a height of 917 ± 19 μm (IV). Scale bars, 1 mm (left) and 200 μm (right). (D) Surface energy indicated by measuring the contact angles formed with a liquid collagen droplet. A significantly increased contact angle occurred with the increase in the density of the microneedles array (5 × 5: 80.38 ± 9.98°, 10 × 10: 104.99 ± 5.64°, and 15 × 15: 122.89 ± 5.28°). (E) FTIR spectra and secondary structure analysis of the natural and methanol-treated samples, respectively. (F) Compression test of SF MNs. The methanol-treated SF microneedle could withstand compressive forces of more than 0.6 N per needle. (G) Swelling ratio of SF MNs after being inserted into porcine skin for 24 h.