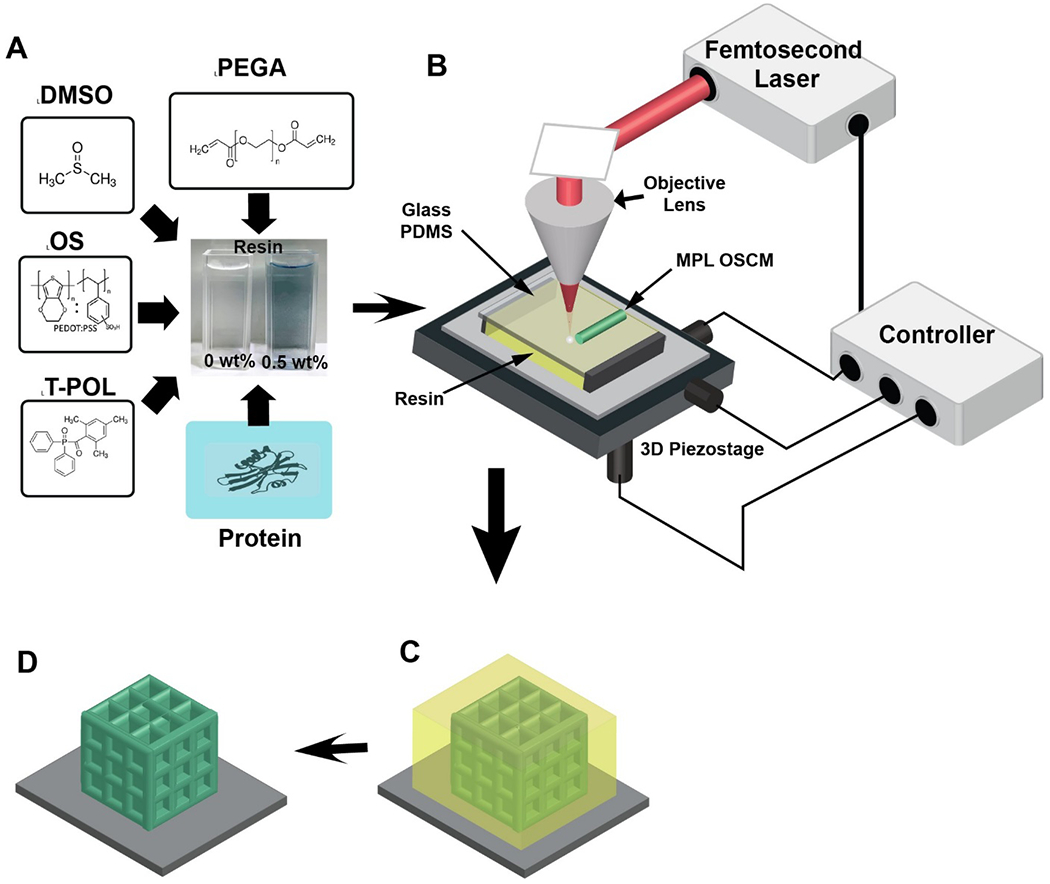

Figure 1.

Resin components and MPL fabrication process. A) Components of the OS composite resin: photopolymer poly(ethylene glycol) diacrylate (PEGA), organic semiconductor (OS) poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) (PEDOT:PSS), photoinitiator 3-(trimethoxysilyl)propyl methacrylate (T-POL), miscible agent dimethyl sulfoxide (DMSO) and proteins such as laminin and glucose oxidase. B) Experimental setup for the MPL process, including resin, glass/PDMS substrates, 3D piezostage, controller, femtosecond (fs) laser, and the objective lens. C) The OS composite resin (yellow color) is crosslinked by a focused fs laser to create 3D OSCMs (green color). D) The sample is then rinsed in ethanol to remove any unsolidified resin, leaving the 3D OSCMs on the substrate.