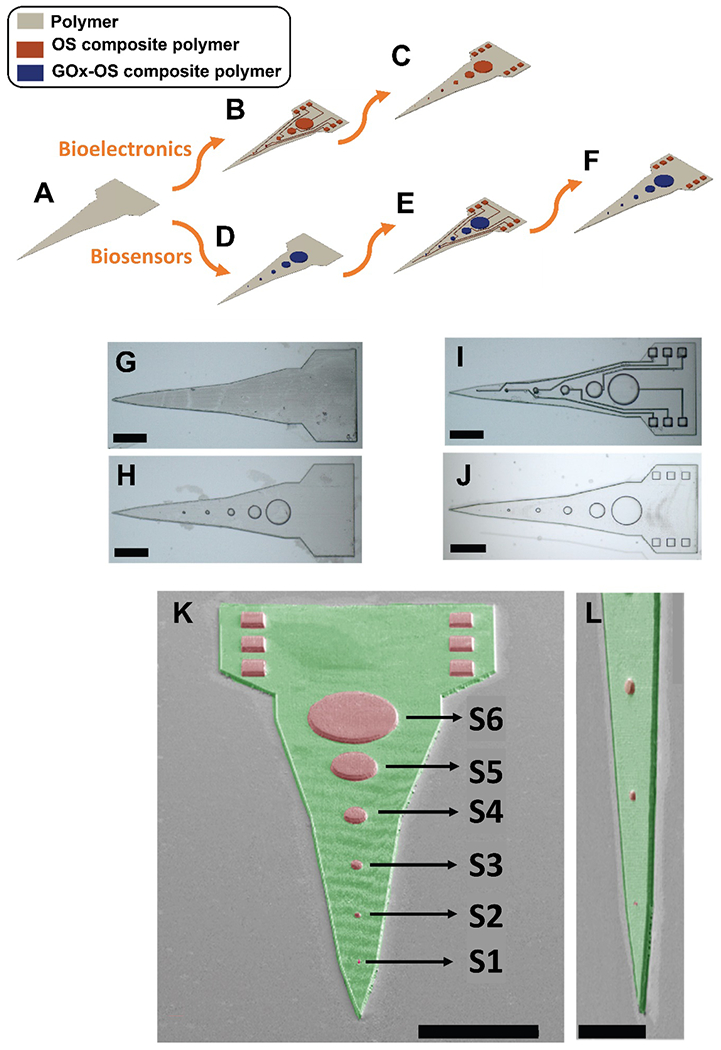

Figure 5.

MPL-based Fabrication process of hybrid Michigan-style microelectrode for bioelectronics and biosensors applications. A-C) Schematic illustrations for fabrication of bioelectronics: A) Construction of insulating electrode shank and base (height: 2 μm) using the polymer resin (without added OS). B) OSCMs including electrode sites (height: 7 μm, diameters: 1, 5, 10, 20, 40, and 80 μm), interconnect cables (width: 1 μm, height: 2 μm), and contact pads (length: 20 μm, width: 20 μm, height: 7 μm) were fabricated using the OS composite resin (OS concentration: 0.5 wt%). C) The insulating layer is fabricated using the polymer resin (without added OS) to encapsulate the interconnect cables (height: 3 μm). D-F) Schematic illustrations for fabrication of biosensors: following construction of insulating electrode shank and base (height: 2 μm) from the polymer resin without added OS (A), D) enzyme-loaded sites are fabricated from OS composite resin containing glucose oxidase (GOx), E) construction of interconnect cables and contact pads using OS composite resin (without enzyme), F) fabrication of insulating layer. G-J) Optical micrograph representations of MPL-fabricated microstructures (scale bars: 50 μm). G) Representation of schematic (A), H) representation of schematic (D), I) representation of schematic (B) and (E), J) representation of schematic illustration (C) and (F). K-L) Pseudo-colored SEM micrographs of MPL-fabricated microelectrode at low and high magnifications, respectively (green represents polymer and red represents OS composite polymer). Scale bars in K and L are 100 μm and 50 μm, respectively.