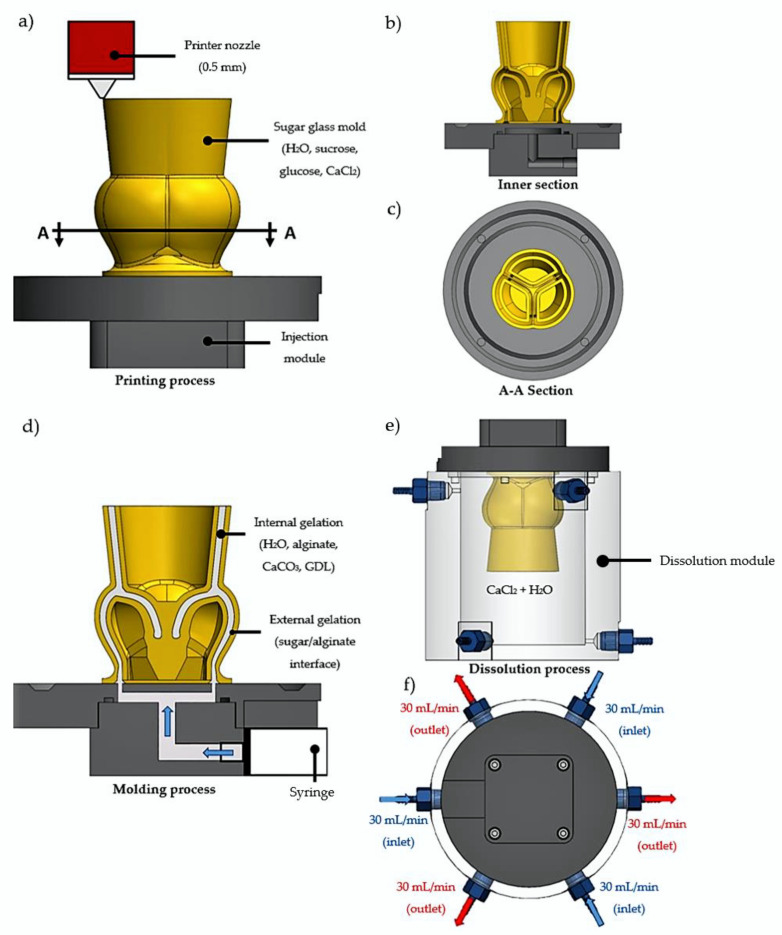

Figure 1.

Schematic of the aortic valve scaffold fabrication. (a) Aortic valve sugar glass mold loaded with CaCl2 and printed with a 0.5 mm custom printer nozzle and a 0.2 mm layer height. (b) Inner section of the mold. (c) A-A section of the mold showing the interior at the mid-sinus. (d) Molding process of the aortic valve scaffold using the syringe loaded with the sodium-alginate formulation containing the sodium alginate loaded with GDL and CaCO3 for internal gelation. External gelation occurred at the sugar/alginate interface. (e) Transferring the mold injected with the sodium-alginate solution into the dissolution module. (f) For the dissolution of the sugar mold, a 90 mL/min total (inlet/outlet) flow of water supplemented with CaCl2 was performed.