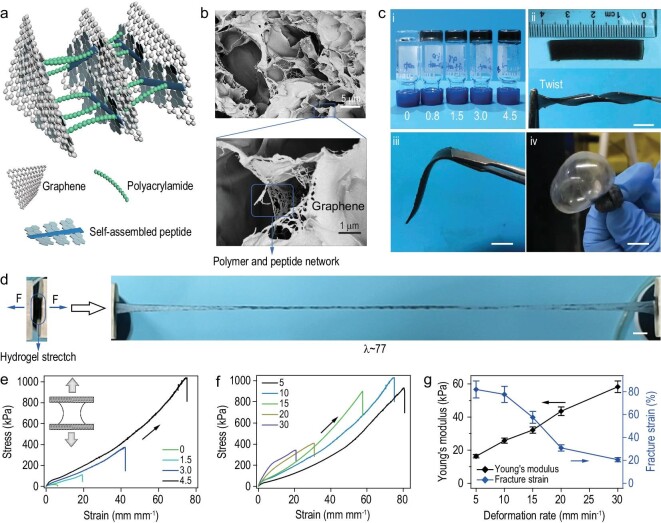

Figure 3.

Design, characterization and mechanical properties of SHARK. (a) Schematic of the SHARK hydrogel network. PCG nanosheets are linked to each other via in situ copolymerization of acrylamide and acrylate-modified Py-GAGAGY peptide. (b) SEM images of the porous structures of the hydrogel. The self-assembled peptide networks can be clearly observed on the graphene sheets in the enlarged view. (c) Optical images of SHARK hydrogels. Scale bar = 5 mm. i. SHARK containing different concentrations of PCG (0, 0.8, 1.5, 3.0 and 4.5 mg mL−1). ii. Flat (top) and twisted (bottom) SHARK bands. iii. SHARK band held by tweezers. iv. SHARK balloon inflated with argon gas. (d) SHARK hydrogel (CPCG = 4.5 mg mL−1) stretched to ∼77 times its initial length in a tensile test. Scale bar = 5 mm. (e) Uniaxial tensile stress-strain curves of SHARK containing different concentrations of PCG (0, 1.5, 3.0 and 4.5 mg mL−1). (f) Uniaxial tensile stress-strain curves of SHARK (CPCG = 4.5 mg mL−1) under different deformation rates ranging from 5 to 30 mm min−1 (2 to 12 mm mm−1 min−1). Both the Young's modulus and the fracture strain depend on the deformation rate, revealing nonequilibrium disruption of weak interactions upon stretching. (g) Deformation rate dependence of the Young's modulus and fracture strain of SHARK in f.