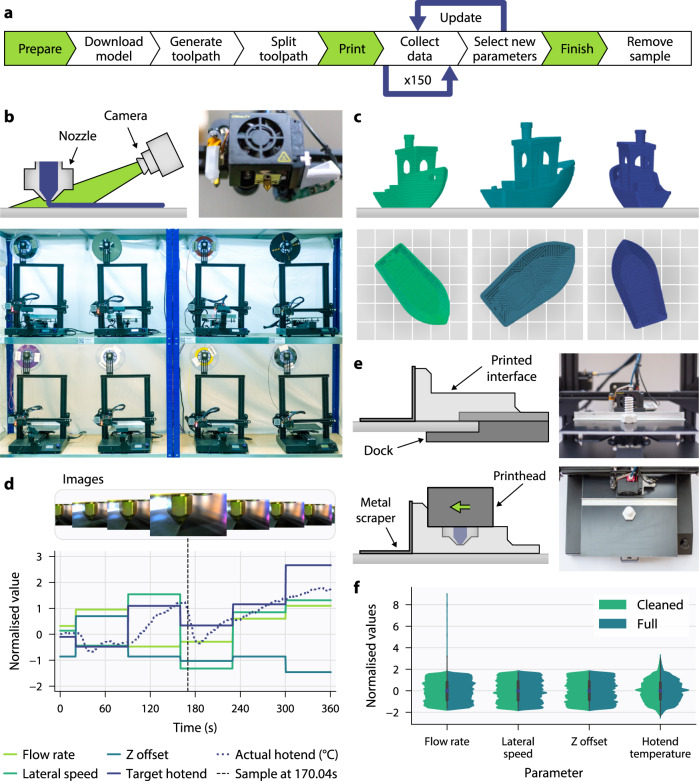

Fig. 1. Overview of the CAXTON system used for automated data collection.

a Workflow for collecting varied datasets from extrusion 3D printers with the automatic labelling of images with printing parameters. b Fleet of eight thermoplastic extrusion 3D printers (Creality CR-20 Pro) equipped with cameras focused on the nozzle tip to monitor material deposition. c Renderings of generated toolpaths for a single input geometry, with randomly selected slicing parameters. d Snapshot of data gathered during an example print showing images with varying parameter combinations. e Design of bed remover and dock utilising existing motion system along with photographs taken during operation. f Distributions of normalised parameters in the full dataset collected by CAXTON containing over 1.2 million samples.