Figure 1.

Preparation of the scaffolds and the RCCS™ bioreactor

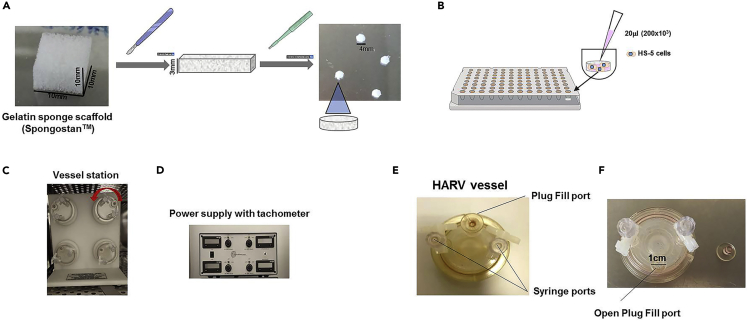

(A) Preparation of scaffolds from a cube of gelatin sponge (Spongostan™).

(B) Positioning of scaffolds in the 96-well suspension culture plate and HS-5 BMSC seeding.

(C and D) The RCCS™ 4DQ bioreactor (Synthecon, Inc,): the bioreactor is composed by a working station (C) with 4 independent positions for vessels and a power supply (D) with a tachometer controlling the speed of rotation of each vessel. The rotation of vessels is counterclockwise and maintains the scaffolds in a free fall condition simulating microgravity. The dynamic culture allows optimal mass transfer, delivery of nutrients and of oxygen, avoiding cell sedimentation.

(E) High Aspect Ratio Vessel (HARV): it is composed by one Plug Fill port, two syringe ports and a silicon membrane for gas exchange.

(F) High Aspect Ratio Vessel (HARV) with the Plug Fill port opened.