Abstract

Aiming at the challenge that environmental protection and high-temperature fluid loss reduction performance of the traditional water-based drilling fluid treatment agent are difficult to balance, our studies added psyllium husk as a high-temperature-resistant and environmentally friendly filtrate reducer to a water-based drilling fluid. The composition, physical and chemical properties, and microstructure of psyllium husk are characterized. Then, the effects of psyllium husk after hot rolling at different temperatures on the rheological properties and fluid loss properties of bentonite-based slurry are evaluated. The results show that the psyllium husk added to the bentonite-based slurry can effectively improve the rheological properties and fluid loss properties of the bentonite-based slurry, and the temperature resistance can reach 160 °C. After hot rolling at 160 °C, adding 1 w/v % psyllium husk can reduce the API fluid loss and high-temperature and high-pressure fluid loss of the bentonite-based slurry by 76.04 and 56.91%, respectively, showing excellent fluid loss reduction performance at high temperatures. The branched structure and uronic acid of psyllium husk can inhibit the degradation of its own molecular structure to a certain extent, which is the fundamental reason why psyllium husk still has excellent fluid loss reduction performance at high temperatures. Psyllium husk is expected to replace some traditional synthetic polymers and be used in environmentally friendly high-temperature-resistant water-based drilling fluids.

1. Introduction

With the development of drilling engineering technology, the depth of drilling is gradually increasing and the formation is becoming more and more complex, which puts forward higher requirements on the performance of the drilling fluid.1−3 During the circulation of the drilling fluid, the liquid phase will invade the formation under the action of the pressure difference. At the same time, the solid phase will form a thinner mud cake in the formation.4−6 Multiple research studies have demonstrated that when the fluid loss of the drilling fluid occurs, it will cause the shale formation to hydrate and swell, which will induce the instability of the borehole wall. When the fluid loss is large, a thicker mud cake will be produced, which is prone to drilling accidents such as wear of drilling tools and stuck drills.6−8 When drilling into deep formations, the components of the drilling fluid are prone to high-temperature degradation and failure,9 thus deteriorating the performance of the drilling fluid2,10 and triggering a series of downhole complex accidents.6 Therefore, the development of high-temperature-resistant drilling fluid treatment agents, effective control of the high-temperature filtration, and wall-building performance of the drilling fluid has always been the research focus of deep well and ultradeep well drilling engineering.

Researchers synthesized copolymers with acrylamide and heat-stable monomers (such as 2-acrylamido-2-methylpropanesulfonate, N-vinylpyrrolidone, etc.).11−14 The temperature resistance has exceeded 160 °C, but it is also affected by the disapproval merits of the high expenditure, harder manufacturing process, environmental protection issues, and many other constraints.15,16 Therefore, it remains a big challenge to execute the research of anti-high-temperature filtration reducers.

With the increasingly stringent environmental regulations, the exploitation of green and environmentally friendly drilling fluid treatment agents is of great significance for protecting the environment. In recent years, researchers have carried out a lot of research and developed a richer variety of environmentally friendly treatment agents.17−19 Among them, because polysaccharide polymers have the advantages of wide sources, low price, easy modification, and biodegradability, they are extensively applied in drilling fluids to improve rheological properties and fluid loss properties,18,20 such as xanthan gum, starch derivatives, cellulose derivatives, and so on. When the hot rolling temperature is greater than 140 °C, it is susceptible to oxidative decomposition or thermal degradation at high temperature, leading to breakage of the molecular chain and losing the control effect on the performance of the drilling fluid.9−11,21

Psyllium is a plant in the genus Plantago, mainly from Iran and India,22,23 which is typically used in the medical field in some countries and has the ability to lower cholesterol and promote intestinal peristalsis.22,24,25 Meanwhile, benefiting from its unique ability to absorb water, thicken, and form gels, it has also been utilized in food production and drug transportation.25,26 The main component of psyllium is highly branched arabinoxylan, where the main chain structure is (1→4)-β-d-xylose and the side chain is located at the position of C-3 and C-2,26−28 which contains a small amount of uronic acid.29 The presence of branched structures in polymer molecules can effectively increase the steric hindrance of the molecular chain and the rigidity of the main chain30,31 and improve the thermal stability of the polymer to a certain extent. It has been reported that uronic acid has the function of the antioxidant properties, which can availably inhibit the oxidative decomposition of polymers.32,33 As the temperature increases, the molecular movement intensifies and the oxidative decomposition rate of the polymer will increase. The presence of uronic acid can preserve the polymer from the oxidative decomposition at high temperatures, thereby enhancing the polymer’s thermal stability performance.

As psyllium husk is an easily biodegradable treatment agent, this article investigates the feasibility of applying it in drilling fluids. First, the composition and structure of psyllium husk are characterized, and then, the influence of psyllium husk on the rheology and fluid loss of water-based drilling fluids is systematically evaluated, and the mechanism of action through relevant analysis and testing methods is carried out. At present, there is no report of the application of natural polysaccharides in drilling fluids at 160 °C. This study will provide a new perspective for the future selection of environmentally friendly treatment agents. This is the highlight of this study.

2. Materials and Methods

2.1. Materials

Psyllium husk is provided by Xianchangyue Biotechnology Co., Ltd. Sodium-based bentonite for the drilling fluid is provided by Shandong Huawei Bentonite Co., Ltd., which meets API standards. Na2CO3, NaCl, CaCl2, and absolute ethanol are all analytical reagents, provided by Sinopharm Chemical Reagent Co., Ltd. All experimental reagents have not been purified.

2.2. Composition Determination of Psyllium Husk

The monosaccharide content of psyllium husk was analyzed by GCMS, which refers to Petal’s method.33 The content of uronic acid was determined according to the method of Blumenkrantz and Asboe-Hansen using d-glucuronic acid as the standard.34

2.3. Water Absorption Measurement

A total of 1.00 g of psyllium husk was accurately weighed and placed in a nonwoven bag. The nonwoven bag was soaked in deionized water to start timing. Once the psyllium husk came in contact with deionized water, the variation in bag weight was weighed and recorded after specific time intervals. Before weighing, the bag was carefully taken out from water and the excessive water was drained for 3 min. The relationship between the water absorption quality of psyllium husk was tested at 20 °C with time.

2.4. Rheological Property Measurement

Psyllium husk of different qualities was added into 350 mL of deionized water, stirred at 8000 rpm for 20 min, and tested for rheology using an Anton Paar MCR72 at a temperature of 25 °C and a shear rate of 0.1–1000 s–1.

The power-law model is used to fit the rheological data. The power-law model mainly describes the exponential relationship between shear stress and shear rate. The important parameters are the flow pattern index (n) and consistency coefficient (K). The fitting formula is as follows

| 1 |

A total of 14.0 g of sodium bentonite and 0.7 g of Na2CO3 are added to 350 mL of deionized water, stirred at a high speed, and let it stand for 24 h in an airtight manner to obtain bentonite-based slurry. Psyllium husk of different qualities was added to the sodium bentonite-based slurry and placed in an aging tank to hot rolling for a period of time to simulate the effect of high temperature on the drilling fluid to evaluate the stability of the drilling fluid. The rheological properties of the drilling fluid before and after hot rolling were tested using a six-speed rotary viscometer.

The ZNN-D6 six-speed rotational viscometer (Qingdao Haitongda) was used to test the apparent viscosity (AV), plastic viscosity (PV), and yield point (YP) of the drilling fluid. The calculation formula is as follows

| 2 |

| 3 |

| 4 |

2.5. Filtration Property Measurement

Psyllium husk of different qualities was added to the sodium bentonite-based slurry, hot rolling was performed at different temperatures, and then tested for API fluid loss using a ZNZ-D6 medium pressure filter loss instrument. The API filter paper is used as the fluid loss medium, and the fluid loss is 30 min under the condition of a pressure difference of 0.7 MPa. High-temperature and high-pressure static fluid loss can simulate the fluid loss of the drilling fluid downhole to a certain extent. After hot rolling, the high-temperature and high-pressure (HTHP) static filtration experiment is carried out. A GGS71-B (Qingdao Haitongda) HTHP loss tester is used for the HTHP static filter loss test. The test temperature is the corresponding hot rolling temperature, the test pressure difference is 3.5 MPa, and the test time is 30 min. The filtrate is collected by a graduated cylinder.

2.6. Biodegradability Evaluation

In terms of toxicity, the concentration for 50% of maximal effect (EC50) was measured as the toxicity level based on the luminescent bacteria method recommended by the National Standards of the People’s Republic of China GB/T 15441-1995 (Water quality determination of the acute toxicity-luminescent bacteria test).

3. Results and Discussion

3.1. Composition and Structure of Psyllium Husk

The chemical composition of the psyllium husk studied in this paper is exhibited in Table 1. It can be concluded that xylose and arabinose have the highest content and are the main components of psyllium husk. Noticeably, psyllium husk also contains a certain concentration of uronic acid, which can scavenge free radicals and exhibit excellent antioxidant properties.26,33

Table 1. Composition of Psyllium Husk.

| composition | relative content/(w/v %) |

|---|---|

| arabinose | 21.4 |

| xylose | 75.4 |

| galactose | 1.6 |

| glucose | 0.6 |

| rhamnose | 0.3 |

| uronic acid | 0.7 |

The molecular structure of the psyllium husk is shown in Figure 1. It is a highly branched arabinoxylan with the main chain structure of (1 → 4)-β-d-xylose, the side chain is located at C-3 and C-2.26−28 It has been demonstrated that the existence of the branched chain structure is more beneficial to improve the rigidity of the molecular main chain and the steric effect between branched chains so as to improve the temperature resistance of polymers.30,31 Meantime, its effective component of uronic acid can effectively remove oxidation groups in polymers and inhibit the oxidative decomposition of polymers. Accordingly, with the increase in temperature, the intensification of molecular thermal motion and acceleration of the oxidative decomposition rate of the polymer will be effectively inhibited due to the existence of uronic acid.26,33 At the same time, the degree of the branched chain structure of the polymer will be further deepened due to the breakage of its molecular chain by increasing temperature, by inference, the rigidity of the molecular main chain continues to improve, and the steric effect between branched chains also improves the ability of the molecular chain to resist thermal decomposition.

Figure 1.

Molecular structure of the psyllium husk.

3.2. Water Absorption

The change in water absorption quality of psyllium husk with time is depicted in Figure 2. It can be seen that with the prolonged water absorption time, the water absorption quality of psyllium husk increases. When the water absorption time is 1440 min, 1.0 g of plantain seed shell powder can adsorb 62.34 g of water molecules. At the same time, the water absorption rate of the psyllium husk decreases with time, indicating that the psyllium husk can adsorb a large number of water molecules in a short time. When the water absorption time is 30 min, the psyllium husk can adsorb 33.16 g of water molecules. This is because the seed shell powder of plantain is a branched polysaccharide, and its molecular branched chain structure has a large number of hydrophilic groups, which can adsorb a large number of water molecules. Meanwhile, the psyllium husk after water absorption will form a hydration membrane to increase the elasticity of the molecular chain, which is conducive to the formation of compressible mud cake to reduce filtration.35,36

Figure 2.

Relationship between psyllium husk water absorption quality and time at 20 °C.

3.3. Microstructure Characterization

The 1 w/v % psyllium husk deionized water suspension was freeze-dried and observed with a scanning electron microscope, as shown in Figure 3. It can be concluded that the molecular chains of psyllium husk are intertwined and connected to form a sheet structure. Figure 3b shows a partially enlarged picture, it can be seen that a large number of nanofibers are intertwined and connected to construct a three-dimensional network structure.37 These reticular structures come together to form a sheet structure with gaps. Moreover, the pores in the three-dimensional network structure are more conducive to the entry of water molecules and form hydrogen bonds with the hydroxyl groups of psyllium husk, showing good hydrophilic ability.

Figure 3.

Scanning electron microscopy (SEM) images of psyllium husk (a) 1000× and (b) 10,000×.

3.4. Rheological Property Measurement

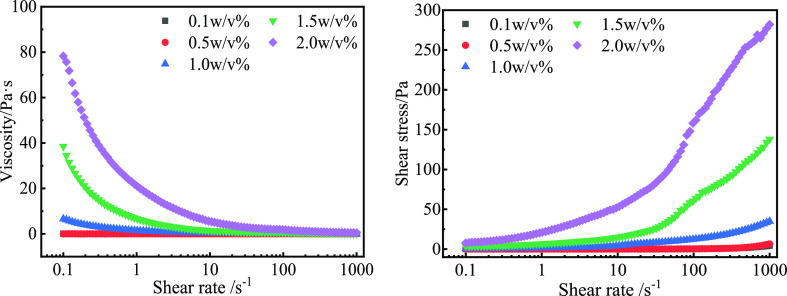

Psyllium husk of different qualities is added to the bentonite-based slurry, and the rheological curve is shown in Figure 4. It can be concluded that the psyllium husk suspension exhibits shear thinning. As the shear rate increases, the viscosity of the psyllium husk suspension decreases with increase in the shear stress. When the shear rate is low, the psyllium husk will adsorb a large number of water molecules, increase the viscosity of the drilling fluid, and help carry cuttings during the circulation of the drilling fluid. As the shear rate increases, polymer molecules move in the direction of flow, the aggregation of polymer chains decreases, and the viscosity of the drilling fluid decreases which is more beneficial to the drilling process.

Figure 4.

Effect of concentration on rheological properties of psyllium husk solution.

The power-law model is used to fit the rheological curve. As shown in Table 2, the suspension of psyllium husk under different concentrations well-conforms to the power-law model and R2 is more than 0.97. The consistency coefficient tends to 1 with the increase in the concentration of psyllium husk, indicating the corresponding increase in the viscosity of the suspension.

Table 2. Rheological Parameters of the Power-Law Model for a Psyllium Husk Suspension at Various Concentrations.

| concentration of psyllium husk/(w/v %) | k/Pa sn | N | R2 |

|---|---|---|---|

| 0.1 | 0.000932 | 1.1632 | 0.991 |

| 0.5 | 0.004893 | 0.9197 | 0.9749 |

| 1.0 | 1.535028 | 0.4653 | 0.9897 |

| 1.5 | 7.162599 | 0.4437 | 0.9876 |

| 2.0 | 21.98374 | 0.4064 | 0.9893 |

The different qualities of psyllium husk are added into the bentonite-based slurry, hot rolling was performed at 160 °C for 16 h, and the rheological parameters are shown in Figure 5. Before and after 160 °C hot rolling, the viscosity of the base slurry increases with the amount of psyllium husk increasing, and the apparent viscosity of the experimental slurry changed little. After hot rolling at 160 °C, the apparent viscosity of the base slurry is maintained at about 22 mPa s when the amount of psyllium husk is 1.0 w/v %; when the dosage is further increased, the apparent viscosity of the base slurry increases sharply to 80 mPa s, which is not conducive to the flow and pumping of the drilling fluid. Therefore, the optimum dosage of psyllium husk is 1.0 w/v % in a water-based drilling fluid.

Figure 5.

Effect of psyllium husk on the viscosity of bentonite-based slurry before and after 160 °C hot rolling. (a) Apparent viscosity and (b) yield point.

The high-temperature stability of the drilling fluid is judged by the rheological parameters after hot rolling at different temperatures, as shown in Figure 6. It can be seen that with the increase in the hot rolling temperature, the viscosity of the bentonite-based slurry decreases. Nevertheless, after the addition of 1.0 w/v % psyllium husk, the apparent viscosity first remains basically unchanged and then significantly decreases. When the hot rolling temperature is lower than 160 °C, the viscosity is basically maintained at about 25 mPa s. When the hot rolling temperature is further increased to 180 °C, the viscosity rapidly decreases to 8 mPa s, indicating that the molecular chain of the psyllium husk is affected,38 basically losing the ability to adjust the viscosity of the bentonite-based slurry. Therefore, psyllium husk can be used in a high-temperature environment of 160 °C.

Figure 6.

Effect of hot rolling temperature on the rheological property of the drilling fluid.

3.5. Filtration Property Measurement

The different qualities of psyllium husk are added into bentonite-based slurry, and its API filtration after hot rolling at different temperatures is tested, as shown in Figure 7. With the increase in hot rolling temperature, the API filtration of bentonite-based slurry increases. After adding 1w/v % psyllium husk, the API filtration decreases slightly with the increase in temperature. After hot rolling at 160 °C for 16 h, the API filtration is 11.6 mL, and the reduction rate of API filtration is 69.87%; when the temperature increases to 180 °C, the API filtration begins to increase which is due to the destruction of the molecular structure of the psyllium husk, hence resulting in poor filtration reduction performance.

Figure 7.

Effect of hot rolling temperature on psyllium husk precursor experimental slurry. (a) Bentonite-based slurry and (b) bentonite-based slurry + 1 w/v % psyllium husk.

With the increase in the amount of psyllium husk before and after 160 °C hot rolling, the API filtration decreases (Figure 8). When the amount of psyllium husk is greater than 1 w/v %, the reduction rate slows down gradually, and the experimental slurry filtration is always less than that before hot rolling. When the dosage of psyllium husk is 1 w/v %, the API filtration before hot rolling is 14 mL, and the filtration reduction rate is 61.11%; after hot rolling at 160 °C, the API filtration is 9.2 mL and the filtration reduction rate is 76.04%, illustrating that the psyllium husk has excellent filtration reduction performance. This is mainly due to the following pieces of evidence: on the one hand, the psyllium husk is mainly adsorbed on the surface of clay particles through hydrogen-bonding, increasing the thickness of the hydration layer and improving the coalescence stability of clay particles so as to produce mud cake with relatively dense structure, reduce the permeability of mud cake, and effectively reduce the fluid loss. On the other hand, with the increase in the amount of psyllium husk, the viscosity of the experimental slurry increases. According to the Darcy formula, the increase in viscosity is also conducive to reduce the fluid loss.

Figure 8.

Effect of the addition of different qualities of psyllium husk on the filtration of bentonite-based slurry before and after 160 °C.

Generally, fluid loss control can be achieved by forming tight mud cakes to effectively plug the pores of the formation or increasing the viscosity of the drilling fluid.39 After the API fluid loss cake is freeze-dried, it is observed using a scanning electron microscope, as shown in Figures 9 and 10. Before hot rolling, the clay particles are connected by edge-to-surface, but due to the aggregation of some clay particles, a large number of irregular pores are formed in the clay. After adding 1 w/v % psyllium husk, filamentous and flaky structures are observed in the mud cake, indicating that it forms a bridge structure, which is beneficial to adsorb water molecules and retard the migration of water molecules. At the same time, it can be used in the mud cake. Spherical insoluble particles are detected on the surface to block pores and participate in the formation of mud cakes, thereby effectively reducing fluid loss. After hot rolling at 160 °C, the clay particles are transformed into a surface-to-surface connection due to dehydration, which causes the pores of the mud cake to increase and enlarge. After adding 1 w/v % psyllium husk, the mud cake has an obvious honeycomb structure, and the bridging effect of the psyllium husk can still be observed, indicating that the psyllium husk can still reduce filtration by adsorbing water molecules at this time.

Figure 9.

Mud cake SEM image of bentonite-based slurry before and after 160 °C hot rolling. (a) Before hot rolling and (b) after hot rolling.

Figure 10.

Mud cake SEM image of 1 w/v % psyllium husk experimental slurry before and after 160 °C hot rolling. (a) Before hot rolling and (b) after hot rolling.

The fluid loss performance evaluation of HTHP at 160 °C and 3.5 MPa is shown in Figure 11. After 160 °C hot rolling, with the increase in psyllium husk addition, the HTHP fluid loss of the experimental slurry first decreases and then changes little. When the added amount of psyllium husk is 1 w/v %, the fluid loss of HTHP is the lowest, which is 81.0 mL, and the reduction rate of fluid loss of HTHP is 56.91%. When the amount of psyllium husk increased further, the HTHP filtration did not change much.

Figure 11.

Effect of different psyllium husk concentrations on the HTHP fluid loss of bentonite-based slurry.

3.6. Anti-pollution Performance Evaluation

3.6.1. Anti-salt Pollution Performance Evaluation

1 w/v % psyllium husk and different concentrations of NaCl are added to the bentonite-based slurry, and the fluid loss performance changes after hot rolling at 160 °C are investigated, as shown in Figure 12. When 30 w/v % NaCl is added to the bentonite-based slurry, the fluid loss increased from 40.4 to 276.8 mL, indicating that the fluid loss could no longer be controlled at this time. After adding 1 w/v % psyllium husk, the API fluid loss decreased to 44.2 mL, and the fluid loss reduction rate is 84.03%.

Figure 12.

Effect of NaCl concentration on filtration performance of the drilling fluid. (a) Bentonite-based slurry and (b) bentonite-based slurry + 1 w/v % psyllium husk.

Studies have shown that under high salinity conditions, the adsorption between the polymer and the clay particles can effectively reduce fluid loss. The electrolyte reduces the solvation ability of water molecules to a certain extent, the electrostatic repulsion between the polymer and the clay particles, and increases the adsorption of anionic polymers on the surface of the clay particles.40 The polymer molecules in water form a stretched structure due to the charge repulsion between the molecules. When the anionic polymer is adsorbed on the surface of the clay particles, it will have a good colloidal stabilization effect on the clay particles and prevent the clay particles from flocculating in a high-salt solution.41 As the concentration of NaCl increases, the flocculation between the clay particles becomes more serious. When the concentration of NaCl increases to 30 w/v %, the fluid loss reduction performance of the psyllium husk on the clay weakens, but compared with the base slurry, it can still effectively inhibit the flocculation of clay particles.

At the same time, the branched structure can be adsorbed on the surface of the clay particles through the hydrogen-bonding of the polyhydroxyl group, which improves the coalescence stability of the clay particles.

3.6.2. Anti-calcium Pollution Performance Evaluation

1 w/v % psyllium husk and different concentrations of CaCl2 are added to the bentonite-based slurry, and the fluid loss performance changes after hot rolling at 160 °C are investigated, as shown in Figure 13. When 0.3 w/v % CaCl2 is added to the bentonite-based slurry, the fluid loss increases from 40.4 to 85.2 mL, indicating that the fluid loss can no longer be controlled at this time. After adding 1 w/v % psyllium husk, the API fluid loss decreases to 66.2 mL, and the fluid loss reduction rate is 22.30%.

Figure 13.

Effect of CaCl2 concentration on filtration performance of the drilling fluid. (a) Bentonite-based slurry and (b) bentonite-based slurry + 1 w/v % psyllium husk.

This is because after hot rolling, Ca2+ will cause edge-to-edge bonding and edge-to-surface bonding between the clays, resulting in a three-dimensional structure, resulting in an increase in filter loss. With the further increase in Ca2+ concentration, the clay particles are transformed into surface-to-surface connection, which makes the clay flocculate and settle and increase the fluid loss.35 After adding 1 w/v % psyllium husk, the low concentration of Ca2+ will promote the adsorption of anionic polymers on the clay surface and prevent the flocculation of clay particles, so the fluid loss will not change much. As the concentration of Ca2+ increases, the flocculation of clay particles leads to an increase in the fluid loss of the drilling fluid.

3.7. Comparison with Conventional Filtration Reducers

The fluid loss reduction performance of different fluid loss additives on bentonite-based slurry is shown in Figure 14. Before hot rolling, several environmentally friendly fluid loss additives can effectively reduce the API fluid loss of bentonite-based slurry. After hot rolling at 160 °C, the molecular structure of the commonly used modified natural polymer fluid loss agent is destroyed, and the fluid loss performance becomes worse, and the fluid loss increases to more than 20 mL. Only the experimental slurry with psyllium husk has excellent fluid loss performance, with a fluid loss of only 9.2 mL, indicating that the temperature resistance of psyllium husk is better than other commonly used environmentally friendly fluid loss reducer and can be applied to 160 °C in the drilling fluid.

Figure 14.

Effect of different environmentally friendly filtrate reducers on the filtration properties of bentonite-based slurry before and after 160 °C hot rolling.

This is because the psyllium husk has a natural branched structure and has better temperature resistance than linear polymers.42 At the same time, the uronic acid contained in the molecular chain of the psyllium shell powder has strong reducing properties, which can inhibit the oxidative decomposition of the polysaccharide polymer, further improve the temperature resistance, and ensure that the molecular structure of the polysaccharide polymer is not damaged to a certain extent.

3.8. Evaluation of Biological Toxicity

Table 3 shows that the EC50 value of the psyllium husk, which meets the national standard GB/T 15441-91 of the People’s Republic of China. It belongs to an environmentally friendly filtration reducer.

Table 3. EC50 Mesurement of Psyllium Husk.

| test number | EC50 value/(mg L–1) | standard/(mg L–1) | result |

|---|---|---|---|

| 1 | 1.2 × 105 | 30,000 | environmentally friendly and non-toxic |

| 2 | 0.94 × 105 | environmentally friendly and non-toxic | |

| 3 | 1.12 × 105 | environmentally friendly and non-toxic |

3.9. Mechanism Analysis

The fluid loss reduction mechanism of psyllium husk is similar to that of other high molecular polymers, mainly including adsorption, thickening, trapping, and physical blocking. At the same time, psyllium husk has excellent water absorption properties which can effectively reduce the content of free water in drilling fluids, form a hydration film, increase the elasticity of molecular chains, and help form compressible mud cakes, thereby reducing fluid loss. However, psyllium husk still exhibits good filtration reduction performance at high temperatures above 140 °C which is unmatched by the existing natural polymer polymers. The branched structure of psyllium husk is one of the reasons for improving its own temperature resistance. The branched structure can improve the polymer’s thermal stability because of the structural rigidity between the molecular main chains and the steric hindrance effect between the branches. At the same time, as the hot rolling temperature increases, the molecular thermal movement intensifies and the natural polymer is easily affected by the dissolved oxygen contained in the drilling fluid, which leads to degradation. Uronic acid can effectively remove free oxidizing groups and substances and inhibit the oxidative degradation of polymers.26,33 Therefore, psyllium husk has a certain concentration of uronic acid which effectively prevents the oxidative degradation of the molecular structure at high temperatures. This provides a reference for the future optimization of other natural polymer materials and provides the possibility to improve the temperature resistance of the drilling fluid treatment agent from another perspective.

4. Conclusions

This article explores the feasibility of using psyllium husk as an environmentally friendly filtration reducer for high-temperature-resistant water-based drilling fluids. Psyllium husk has excellent temperature resistance. After hot rolling at 160 °C, when the concentration of psyllium husk is 1 w/v %, the reduction rates of API fluid loss and HTHP fluid loss are 76.04 and 56.91%, respectively, and much lower than other commonly used natural polymer fluid loss additives. Simultaneously, the psyllium husk shows excellent anti-pollution performance. The fluid loss reduction mechanism of psyllium husk is similar to that of other high molecular polymers, mainly including adsorption, thickening, trapping, and physical blocking. The three-dimensional network structure contained in psyllium husk exhibits excellent water absorption and viscosity-increasing properties. In addition, the adsorption group contained in the molecular chain can be adsorbed on the surface of the clay, effectively improving the agglomeration stability of the clay. Thickening of the hydration layer is beneficial to reduce fluid loss and inhibit shale hydration. Meanwhile, the branched side chains and uronic acid of the psyllium husk improve the thermal stability of the molecule and retard high-temperature decomposition. In addition, psyllium husk is environmentally friendly, renewable, and low in cost and can replace some natural polymers or synthetic polymer filtrate reducers.

Acknowledgments

The authors express their gratitude to X.K., W.L., and Y.W. from China University of Petroleum (China East) for their help in the experimental data process.

Glossary

Abbreviations

- AHR

after hot rolling

- BHR

before hot rolling

- LV-CMC

low-viscosity carboxylmethyl cellulose

- CMS

carboxymethyl starch

- LV-PAC

low-viscosity polyanionic cellulose

- XC

xanthan gum

Author Contributions

∇ X.C. and X.G. contributed equally to this work.

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

The authors declare no competing financial interest.

References

- Son A. J.; Ballard T. M.; Loftin R. E. Temperature-Stable Polymeric Fluid-Loss Reducer Tolerant to High Electrolyte Contamination. SPE Drilling Engineering 1987, 2, 209–217. 10.2118/13160-pa. [DOI] [Google Scholar]

- Akpan E. U.; Enyi G. C.; Nasr G.; Yahaya A. A.; Ahmadu A. A.; Saidu B. Water-based drilling fluids for high-temperature applications and water-sensitive and dispersible shale formations. J. Pet. Sci. Eng. 2019, 175, 1028–1038. 10.1016/j.petrol.2019.01.002. [DOI] [Google Scholar]

- Salmachi A.; Talemi P.; Tooski Z. Y.. Psyllium husk in water-based drilling fluids: an environmentally friendly viscosity and filtration agent. Abu Dhabi International Petroleum Exhibition & Conference: Abu Dhabi, 7–11 November, 2016.

- Amanullah M.; Ramasamy J.; Al-Arfaj M. K.; Aramco S. Application of an indigenous eco-friendly raw material as fluid loss additive. J. Pet. Sci. Eng. 2016, 139, 191–197. 10.1016/j.petrol.2015.12.023. [DOI] [Google Scholar]

- Saboori R.; Sabbaghi S.; Kalantariasl A. Improvement of rheological, filtration and thermal conductivity of bentonite drilling fluid using copper oxide/polyacrylamide nanocomposite. Powder Technol. 2019, 353, 257–266. 10.1016/j.powtec.2019.05.038. [DOI] [Google Scholar]

- Zhong H.; Gao X.; Zhang X.; Chen A.; Qiu Z.; Kong X.; Huang W. Preparation, characterization and filtration control properties of crosslinked starch nanospheres in water-based drilling fluids. J. Mol. Liq. 2021, 325, 1–14. 10.1016/j.petlm.2021.02.001. [DOI] [Google Scholar]

- Ezell R. G.; Ezzat A. M.; Turner J. K.; Wu J. J.. New Filtration-Control Polymer for Improved Brine-Based Reservoir Drilling-Fluids Performance at Temperatures in Excess of 400°F and High Pressure. SPE International Symposium and Exhibition on Formation Damage Control: Lafayette, 10–12 February 2010.

- Zhang W.; Eckert A.. Numerical Investigation of the Influence of Cement Failure to Micro-annuli Generation; American Rock Mechanics Association, 2018. [Google Scholar]

- Galindo K. A.; Zha W.; Zhou H.; Deville J. P.. Clay-Free High Performance Water-Based Drilling Fluid for Extreme High Temperature Wells. SPE/IADC Drilling Conference and Exhibition: London, 17–19 March 2015.

- Hamad B. A.; He M.; Xu M.; Liu W.; Mpelwa M.; Tang S.; Jin L.; Song J. A Novel Amphoteric Polymer as a Rheology Enhancer and Fluid-Loss Control Agent for Water-Based Drilling Muds at Elevated Temperatures. ACS Omega 2020, 5, 8483–8495. 10.1021/acsomega.9b03774. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Perricone A. C.; Enright D. P.; Lucas J. M. Vinyl Sulfonate Copolymers for High-Temperature Filtration Control of Water-Based Muds. SPE Drilling Engineering 1986, 1, 358–364. 10.2118/13455-pa. [DOI] [Google Scholar]

- Behnamanhar H.; Noorbakhsh S. S.; Maghsoudloojafari H. Environmentally Friendly Water-Based Drilling Fluid for Drilling of Water-Sensitive Formations. J. Petrol. Gas Explor. Res. 2014, 4, 60–71. [Google Scholar]

- Bai X.; Yang Y.; Xiao D.; Pu X.; Wang X. Synthesis, characterization, and performance evaluation of the AM/AMPS/DMDAAC/SSS quadripolymer as a fluid loss additive for water-based drilling fluid. J. Appl. Polym. Sci. 2015, 132, 41762. 10.1002/app.41762. [DOI] [Google Scholar]

- Xie B.; Liu X. Thermo-thickening behavior of LCST-based copolymer viscosifier for water-based drilling fluids. J. Pet. Sci. Eng. 2017, 154, 244–251. 10.1016/j.petrol.2017.04.037. [DOI] [Google Scholar]

- Ghaderi S.; Haddadi S. A.; Davoodi S.; Arjmand M. Application of sustainable saffron purple petals as an eco-friendly green additive for drilling fluids: A rheological, filtration, morphological, and corrosion inhibition study. J. Mol. Liq. 2020, 315, 113707. 10.1016/j.molliq.2020.113707. [DOI] [Google Scholar]

- Wang K.; Jiang G.; Liu F.; Yang L.; Ni X.; Wang J. Magnesium aluminum silicate nanoparticles as a high-performance rheological modifier in water-based drilling fluids. Appl. Clay Sci. 2018, 161, 427–435. 10.1016/j.clay.2018.05.012. [DOI] [Google Scholar]

- Hall L. J.; Deville J. P.; Araujo C. S.; Li S.; Rojas O. J.. Nanocellulose and its derivatives for high-performance water-based fluids. SPE International Conference on Oilfield Chemistry: Texas, 3–5 April 2017.

- Okon A. N.; Akpabio J. U.; Tugwell K. W. Evaluating the locally sourced materials as fluid loss control additives in water-based drilling fluid. Heliyon 2020, 6, e04091 10.1016/j.heliyon.2020.e04091. [DOI] [PMC free article] [PubMed] [Google Scholar]

- De Oliveira V. A. V.; dos Santos Alves K.; da Silva-Junior A. A.; Araújo R. M.; Balaban R. C.; Hilliou L. Testing carrageenans with different chemical structures for water-based drilling fluid application. J. Mol. Liq. 2020, 299, 112139. 10.1016/j.molliq.2019.112139. [DOI] [Google Scholar]

- Akbari I.; Ghoreishi S. M. Generation of porous structure from basil seed mucilage via supercritical fluid assisted process for biomedical applications. Pharmaceut. Sci. Dev. Res. 2017, 3, 30–35. [Google Scholar]

- Heier K. H.; Kayser C.; Produkte C.. Vinylsulfonate-vinylamide copolymers and cross-linkable modifications thereof up-to-date chemicals for HTHP drilling, cementing and completion fluids. AADE Fluids Conference and Exhibition: Houston, 8–9 April, 2008.

- Dhar M. K.; Kaul S.; Sareen S.; Koul A. K. Plantago ovata: genetic diversity, cultivation, utilization and chemistry. Plant Genet. Resour. 2005, 3, 252–263. 10.1079/pgr200582. [DOI] [Google Scholar]

- Van Craeyveld V.; Delcour J. A.; Courtin C. M. Extractability and chemical and enzymic degradation of psyllium (Plantago ovata Forsk) seed husk arabinoxylans. Food Chem. 2009, 112, 812–819. 10.1016/j.foodchem.2008.06.035. [DOI] [PubMed] [Google Scholar]

- Wei Z.-h.; Wang H.; Chen X.-y.; Wang B.-s.; Rong Z.-x.; Wang B.-s.; Su B.-h.; Chen H.-z. Time- and dose-dependent effect of psyllium on serum lipids in mild-to-moderate hypercholesterolemia: a meta-analysis of controlled clinical trials. Eur. J. Clin. Nutr. 2009, 63, 821–827. 10.1038/ejcn.2008.49. [DOI] [PubMed] [Google Scholar]

- Mallikarjunan N.; Deshpande R.; Jamdar S. N. Radiation processing of psyllium and its application in development of low glycaemic food. Radiat. Phys. Chem. 2021, 186, 109477. 10.1016/j.radphyschem.2021.109477. [DOI] [Google Scholar]

- Patel M. K.; Tanna B.; Gupta H.; Mishra A.; Jha B. Physicochemical, scavenging and anti-proliferative analyses of polysaccharides extracted from psyllium (Plantago ovata Forssk) husk and seeds. Int. J. Biol. Macromol. 2019, 133, 190–201. 10.1016/j.ijbiomac.2019.04.062. [DOI] [PubMed] [Google Scholar]

- Kaialy W.; Emami P.; Asare-Addo K.; Shojaee S.; Nokhodchi A. Psyllium: a promising polymer for sustained release formulations in combination with HPMC polymers. Pharm. Dev. Technol. 2014, 19, 269–277. 10.3109/10837450.2013.775156. [DOI] [PubMed] [Google Scholar]

- Ladjevardi Z. S.; Gharibzahedi S. M. T.; Mousavi M. Development of a stable low-fat yogurt gel using functionality of psyllium (Plantago ovata Forsk) husk gum. Carbohydr. Polym. 2015, 125, 272–280. 10.1016/j.carbpol.2015.02.051. [DOI] [PubMed] [Google Scholar]

- Ren Y.; Yakubov G. E.; Linter B. R.; MacNaughtan W.; Foster T. J. Temperature fractionation, physicochemical and rheological analysis of psyllium seed husk heteroxylan. Food Hydrocolloids 2020, 104, 105737. 10.1016/j.foodhyd.2020.105737. [DOI] [Google Scholar]

- Jiang C.; Yu B.; Ma Q.; Dong H.; Dong H.; Zhao H.; Sakinejad P.; Luo Y.; Tang Y. Crosslinked polymers as “smart” viscosifiers used in hostile environments. J. Pet. Sci. Eng. 2019, 173, 1332–1339. 10.1016/j.petrol.2018.11.003. [DOI] [Google Scholar]

- Thaemlitz C.; Patel A.; Coffin G.; Conn L.. A New Environmentally Safe High-Temperature, Water-Base Drilling Fluid System. SPE/IADC Drilling Conference: Amsterdam, 4–6 March 1997.

- Wahid A.; Mahmoud S. M. N.; Attia E. Z.; Yousef A. E.-S. A.; Okasha A. M. M.; Soliman H. A. Dietary fiber of psyllium husk (Plantago ovata) as a potential antioxidant and hepatoprotective agent against CCl4-induced hepatic damage in rats. South Afr. J. Bot. 2020, 130, 208–214. 10.1016/j.sajb.2020.01.007. [DOI] [Google Scholar]

- Patel M. K.; Tanna B.; Mishra A.; Jha B. Physicochemical characterization, antioxidant and anti-proliferative activities of a polysaccharide extracted from psyllium (P. ovata) leaves. Int. J. Biol. Macromol. 2018, 118, 976–987. 10.1016/j.ijbiomac.2018.06.139. [DOI] [PubMed] [Google Scholar]

- Blumenkrantz N.; Asboe-Hansen G. New method for quantitative determination of uronic acids. Anal. Biochem. 1973, 54, 484–489. 10.1016/0003-2697(73)90377-1. [DOI] [PubMed] [Google Scholar]

- Gao X.; Zhong H.-Y.; Zhang X.-B.; Chen A.-L.; Qiu Z.-S.; Huang W.-A. Application of sustainable basil seed as an eco-friendly multifunctional additive for water-based drilling fluids. Petrol. Sci. 2021, 18, 1163–1181. 10.1016/j.petsci.2021.05.005. [DOI] [Google Scholar]

- Li J.; Liu Y.; Luo J.; Liu P.; Zhang C. Excellent lubricating behavior of Brasenia schreberi mucilage. Langmuir 2012, 28, 7797–7802. 10.1021/la300957v. [DOI] [PubMed] [Google Scholar]

- Samateh M.; Pottackal N.; Manafirasi S.; Vidyasagar A.; Maldarelli C.; John G. Unravelling the secret of seed-based gels in water: the nanoscale 3D network formation. Sci. Rep. 2018, 8, 7315. 10.1038/s41598-018-25691-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Vargas J.; Roldán L. J.; Lopera S. H.; Cardenas J. C.; Zabala R. D.; Franco C. A.; Cortés F. B.. Effect of silica nanoparticles on thermal stability in bentonite free water-based drilling fluids to improve its rheological and filtration properties after aging process. Offshore Technology Conference Brasil: Rio de Janeiro, 29–31 October 2019.

- Hall L. J.; Deville J. P.; Santos C. M.; Rojas O. J.; Araujo C. S.. Nanocellulose and biopolymer blends for high-performance water-based drilling fluids. IADC/SPE Drilling Conference and Exhibition, Texas 6–8 March, 2018.

- Shah S.; Heinle S. A.; Glass J. E.. Water-soluble polymer adsorption from saline solutions. SPE Oilfield and Geothermal Chemistry Symposium: Arizona, 9–11 March, 1985.

- Burchill S.; Hall P. L.; Harrison R.; Hayes M. H. B.; Langford J. I.; Livingston W. R.; Smedley R. J.; Ross D. K.; Tuck J. J. Smectite-polymer interactions in aqueous systems. Clay Miner. 1983, 18, 373–397. 10.1180/claymin.1983.018.4.04. [DOI] [Google Scholar]

- Guo Q.; Cui S. W.; Wang Q.; Goff H. D.; Smith A. Microstructure and rheological properties of psyllium polysaccharide gel. Food Hydrocolloids 2009, 23, 1542–1547. 10.1016/j.foodhyd.2008.10.012. [DOI] [Google Scholar]