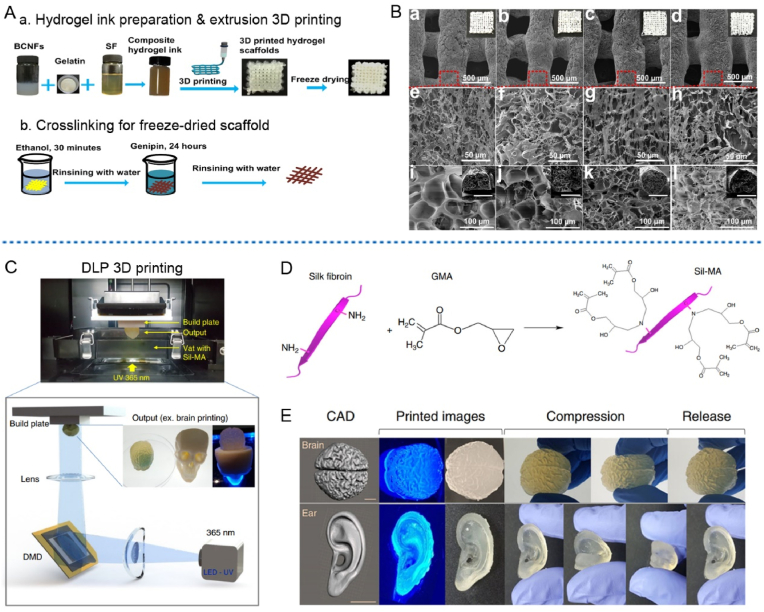

Fig. 5.

Fabrication of SF based bioinks and corresponding printability evaluation by using extrusion or DLP printers. (A) Schematic illustration of the processing route for preparing SF/gelatin/BCNFs hydrogel bioink and corresponding 3D printed scaffold. (B) SEM images of (a, e, i) BCNFs-0 wt%, (b, f, j) BCNFs-0.35 wt%, (c, g, k) BCNFs-0.70 wt%, (d, h, l) BCNFs-1.40 wt% scaffolds to show the hierarchical structure of the printed scaffolds. (a–h) Surface observation of printed scaffolds. (i–l) Cross section of printed filaments (inserted scale bars: 500 μm). (C) Schematic presentation of the DLP bioprinting procedure using DLP printer and Sil-MA bioink. DMD was the digital micromirror device. (D) Schematic illustration of the chemical modification of SF molecule with GMA to fabricate Sil-MA bioink. Herein, GMA is a donor of vinyl double bond as a UV-crosslinking site. (E) CAD models and corresponding gross views of the 3D printed brain and ear shape mimicked RSF scaffolds. Scale bar indicates 1 cm. Images (A)–(B) were modified with permission [91]. Copyright 2019, Elsevier Ltd. Images (C)–(E) were modified with permission [86]. Copyright 2018, Springer Nature.