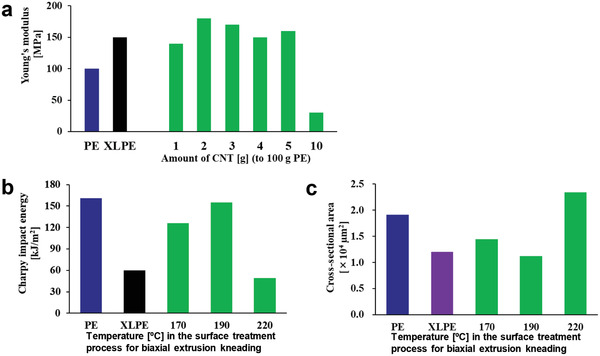

Figure 11.

Mechanical properties of MWCNT/UHMWPE composites. PE: UHMWPE. XLPE: crosslinked UHMWPE. a) Tensile testing of MWCNT/UHMWPE composite test pieces showed that Young's modulus is maximized at a 100:2 composition of UHMWPE and CNTs to make the composite harder than crosslinked UHMWPE. b) The temperature in the last stage of processing using a twin‐screw extruder‐kneader (surface treatment step) and the absorption energy of the prepared test piece in the Charpy impact test are measured. The impact absorption energy is maximized at 190 °C processing to a level equivalent to that obtained with non‐MWCNT‐composite UHMWPE. c) In the wear resistance test, cross‐sectional areas with surface wear are measured and evaluated. When the test piece is processed at 190 °C in the surface treatment step of twin‐screw extrusion‐kneading, the wear resistance is maximized to a level equivalent to that of crosslinked UHMWPE. Adapted with permission.[ 33 ] Copyright 2020, ACS Publications.