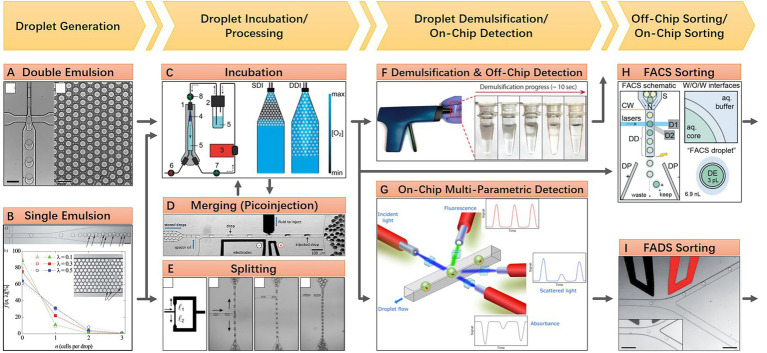

Figure 1.

A general workflow of floating droplet microfluidics. (A) Generating water-in-oil-in-water double emulsion droplets in a PDMS microfluidic chip, the monodispersed double emulsion droplets are compatible with a commercial flow cytometer (Reprinted from Bauer et al., 2010 with the permission of Royal Society of Chemistry); (B) Generating water-in-oil single emulsion droplets in a PDMS microfluidic chip, individual cells are encapsulated during droplet generation and distribution of cells in droplets follows a Poisson distribution. The monodispersed single emulsion droplets are more flexible to be handled and processed (Reprinted from Köster et al., 2008 with the permission of Royal Society of Chemistry); (C) A customized off-chip droplet incubator with enhanced oxygen supply (Reprinted from Mahler et al., 2015 with the permission of Royal Society of Chemistry); (D) An electrically induced droplet merging method called picoinjection for selective adding new reagents into droplets (Reprinted from Abate et al., 2010 with the permission of National Academy of Sciences); (E) A geometry induced droplet splitting method for removing partial contents with desired ratio (Reprinted from Link et al., 2004 with the permission of American Physical Society and the author); (F) An electric induced droplet demulsification method for downstream treatments after droplet processing (Reprinted from Karbaschi et al., 2017 with the permission of AIP Publishing); (G) On-chip multi-parametric detection after droplet incubation (Reprinted from Hengoju et al., 2020 with the permission of AIP Publishing); (H) Off-chip sorting of double emulsion droplets using commensal flow cytometer (Reprinted from Brower et al., 2020 with the permission of Royal Society of Chemistry); (I) On-chip sorting of single emulsion droplets using microfluidic sorter (Reprinted from Baret et al., 2009 with the permission of Royal Society of Chemistry).