Abstract

One of the inevitable problems encountered during the petroleum well drilling process is “lost circulation” in which part of the drilling fluid is lost into the formation. A combination of nanoparticles with their unique properties and cost-effective biodegradable materials can play an effective role in treating fluid loss. In this study, our aim was to formulate drilling fluids modified with nanoparticles, pomegranate peel powder, and Prosopis farcta plant powder. The drilling fluids were identified and recognized using scanning electron microscopy, X-ray diffraction, and Fourier transform infrared spectroscopy techniques. Furthermore, experimental tests were conducted in order to investigate the performance of the newly formulated drilling fluid in improving fluid loss characteristics. The obtaining results have shown that adding 0.3 wt % of pomegranate peel powder to the reference (base) drilling fluid reduces the filter loss volume to 7.9 mL compared to the reference fluid (11.6 mL). As the optimal concentration of TiO2 was mixed with 0.3 wt % of pomegranate peel powder then added to the reference fluid, the filter loss volume was reduced to 8.6 mL.

1. Introduction

The demand for oil and gas has increased enormously, also increasing the need for cost-effective techniques to obtain them. Nonetheless, the drilling process should be safe, environmentally friendly, and economically feasible.1 During the drilling and production processes in the petroleum industry a large number of problems are faced. For instance, while the fluids are circulating in the borehole, some amounts of fluids, e.g., drilling fluid or completion fluid, can be lost underground to the subsurface formation.2 Consequently, fluid loss is considered as a very serious problem that is faced during most of the drilling processes.3 Fluid loss becomes more critical as the differential pressure and circulation rate between the circulating fluid and wellbore increases.3,4 Nanotechnology can be used in drilling technology in the oil and gas industry and provide many great potential advancements, especially in solving the various problems in the field. For instance, the addition of nanomaterials, i.e., nanoparticles, improves the rheological and filtration characteristics of the drilling fluids.5

As environmental awareness increases worldwide, especially in the oil and gas industry, and environmental protection agencies set stringent and firm regulations, rules, guidelines, and standards pertaining to management of drilling waste, obeying the rules and regulations as well as using, developing, and practicing environmentally friendly drilling fluids so that the side effect of the produced drilling waste is reduced on the environment becomes necessary. Therefore, several projects and experiments have been conducted for the purpose of mitigating the produced waste in the drilling and completion processes.6 Therefore, pro-environmental research efforts have become interesting topics to promote the application of biodegradable and ecofriendly waste materials as drilling fluid additives. One of the attempts in this wok was searching and looking for the proper use of agro-waste in formulating the drilling fluids because most of the waste materials produced in agriculture industry are harmless to human beings and the environment.7

Previous research and studies that were done on the effects of nanoparticles and naturally biodegradable materials on the rheological and filtration properties of the drilling fluids are being discussed. For example, Ragab and Noah8 discovered that using nanosilica in concentration 20–30% (by weight) reduces fluid loss by 56% when compared to the reference drilling fluid. Likewise, during their experiment evaluating the effects of nanosilica, Ismail9 found that the addition of 0.01 g of the nanoparticle to the drilling fluid at 200 °F gives a fluid loss volume of only 6.5 mL. Furthermore, Ismail9 pointed out that when TiO2 is added to a water-based drilling fluid reductions of 50% in fluid loss and 30% in filter cake thickness are achieved. Additionally, Nmegbu and Bari-Agara1 studied the corncob cellulose’s impacts on the water-based drilling fluids. The results suggest that corncob cellulose is a good candidate for controlling fluid loss because the drilling fluid formulated from corncob cellulose lowers the fluid loss to between 5.2 and 5.8 mL. Okon and co-workers10 delved into the use of rice husk as a fluid loss control additive by conducting several experiments. The results depict that when 20 g of rice husk is added to 350 mL of drilling fluid, fluid loss reduces by 65%. Furthermore, Hossain and Wajheeuddin11 examined the effect of powdered grass addition with various particle size distributions to the water-based drilling fluid on the rheological properties and filtration characteristics. The results show that the optimum concentration is 0.75 ppb of grass particles in the drilling fluid at 300 mL in which the fluid loss is reduced by 25%. Recently, Al-Saba and co-workers6 studied the effects of 20 biodegradable waste materials, including pomegranate peels, soy bean peels, henna, and tamarind gum, on the rheological properties and filtration characteristics. The optimum concentration of soya bean peel powder was found to be 5 ppb to prepare a drilling fluid which can be used as a filtration controlling agent and treat fluid loss up to 60%. Table 1 summarizes the most commonly used naturally biodegradable materials and nanomaterials in drilling fluids in the petroleum industry.

Table 1. Summary of the Published Research Studies Investigated Biodegradable Waste Materials and Nanoparticles within the Drilling Fluid.

| ref | biodegradable materials and NPs | optimum concentration | optimum results |

|---|---|---|---|

| Okon et al.10 | Rice husk | 20 g per 350 mL | Reduced the fluid loss 64.89% compared to PAC (59.57%) and CMC (62.77%), mud cake thickness of 3.2 mm |

| Hossain and Wajheeuddin11 | Grass | 0.75 ppb in drilling fluid (300 μm) | 25% filtration loss control |

| Dagde and Nmegbu12 | Cellulose processed from groundnut husk | 4.0 g | Fluid loss 6.5 m/s with maximum percentage deviation of −0.02% compared to PAC |

| Amanullah et al.13 | Date seed powder (DSP) | 6 g | Spurt reduction by 40% compared to clay-free starch contain drilling mud and HPHT fluid loss reduction by 60%. |

| Sharma and Vikas14 | Tamarind gum and tragacanth | 0.1% PAC and 0.2% Tamarind Gum | API filter press reduction of 12 mL and 21.40 mDarcy |

| Nmegbu and Bari-Agara1 | Corn cob | 2 g | 5.2 to 5.6 m/s lower fluid loss |

| Davoodi et al.15 | Pistachio shell powder (PSP) | 9 g of PSP-1 in 350 mL | Efficiency with 44% fluid loss reduction and the highest value of plastic viscosity, yield point, and gel strength |

| Al-saba et al.6 | Among 20 waste materials soya bean peel was most efficient | 2 ppb | Reduced the fluid loss up to 60% and enhanced yield point 330% and gel strength 640% |

| Ragab and Noah8 | Nanosilica | 20–30 wt % | Reduced up to 56% of the fluid loss compared to ordinary drilling fluids |

| Vryzas and Kelessidis16 | Iron oxide (Fe2O3) | 0.5 w/w % | Maximum reduction in filtration loss, which was 42.5% in comparison to the base fluid alone |

| Silica nanoparticles | 0.5% and 1.5% (w/w) | Increases of filtration volume 54.1% and 46.8% were observed, respectively | |

| Ismail9 | Nanosilica | 0.01 g | The temperature of 200 °F provided 6.5 mL fluid loss, which was the lowest. |

| Mahmoud et al.17 | Ferric oxide | 0.5 wt % | The best improvement by reducing the filtrate volume by 42.7% compared to the base fluid |

The primary objective of this study was to formulate an environmentally friendly agro-waste and nanoparticle modified drilling fluid with enhanced filtration characteristics such as pomegranate peel powder (PPP). The novelty of this work is using Prosopis farcta plant powder (PFPP) for the first time as a drilling fluid additive which is obtained from a local field. P. farcta is a deciduous, much-branched subshrub that usually grows about 30–80 cm tall or sometimes has a length of 2–3 m.25P. farcta is usually found in a more climbing environment and has deep roots into the ground that can spread freely. According to Shahbazi et al.,26 this plant can be used in many applications of medicine and has been reported as a weed in some places in Iraq and Iran. Here, we tested the effects of PFPP, PPP, SiO2, and TiO2 respectively. Later, the combination of the mentioned biodegradable waste materials with TiO2 and SiO2 at different concentrations was studied. Both SiO2 and TiO2 were used in this study based on the premise that these two nanoparticles provided satisfying and rewarding results in the previous works of other researchers. In addition, by reusing previously worked on nanoparticles, we have a chance to compare our results with theirs to assess the validity and accuracy of the results.

2. Materials and Methodology

2.1. Materials

Purified chemicals, bentonite, soda ash, polymer, and NaOH as well as nanomaterials with sizes ranging between 1 and 100 mn were purchased from companies as commercial materials. The P. farcta and pomegranate were collected at a local field. The P. farcta seeds and pomegranate peels were left at room temperature to dry and were powdered by grinding to small particles as shown in Figure 1.

Figure 1.

Biodegradable materials used in the study.

2.2. Preparation of the Base-Drilling Fluid

The base drilling fluid sample was essentially composed of water (base fluid) and bentonite in addition to other additives, such as caustic soda (NaOH) for controlling alkalinity, soda ash (Na2CO3) for treating contamination by Ca ions, and starch, which is a fluid loss agent. The drilling fluid base samples are prepared with an API-SPEC-13A-2010 standard in accordance with a recent published paper by Ali et al.18

The base drilling fluid was mixed for 30 min using a 3-speed Type GM20 Hamilton Beach mixer. The concentrations of the materials used for preparing 400 mL of the base drilling fluid are shown in Table 2. Drilling fluid samples were formulated using a 3-speed Type GM20 Hamilton Beach Commercial mixer, a Series 300 LPLT Filter Press was used to test the fluid loss, and the rheological properties were obtained using a FANN 35 Viscometer.

Table 2. Composition of the Base-Drilling Fluid Sample.

| Materials | Bentonite (gm) | Water (mL) | Soda ash (gm) | Polymer (gm) | NaOH (gm) |

| Concentration | 20 | 350 | 0.50 | 0.50 | 0.10 |

2.3. Preparation of the Novel Drilling Fluids

Excluding the base sample, 24 other drilling fluid samples were prepared by adding different additives, such as nanoparticles (titanium dioxide, TiO2, and silicon dioxide, SiO2) and biodegradable plant powder (pomegranate peel and local P. farcta plant powders) into the base drilling fluid at different concentrations (see Figure 2). Basically, different types of novel drilling fluids were prepared. The selected nanoparticles were added to the base drilling fluid at the same concentrations of 0.04, 0.08, and 0.12 wt % to prepare nanofluids (see Table 3). Initially, the selected nanoparticles were separately mixed with water using the UH-IID ultrasonic homogenizer for 2 h. Then, the bentonite and other basic materials of the drilling fluid were mixed with the prepared SiO2- and TiO2-based nanofluids using a 3-speed Type GM20 Hamilton Beach Commercial mixer for 1 h.

Figure 2.

Schematic diagram illustrates the experimental steps of the drilling fluid preparation.

Table 3. Biodegradable and Nanodrilling Fluids Prepared by Mixing Pomegranate Peel Powder, P. farcta Plant Powder, Titanium Dioxide, and Silicon Dioxide with the Base Drilling Fluid.

| Biodegradable

drilling fluid |

Nanodrilling

fluid |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PPM |

PFM |

SNF |

TNF |

||||||||||

| Drilling fluid component | Drilling fluid | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 |

| Bentonite, g | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Water, mL | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 |

| Soda ash, g | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 |

| Polymer, g | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 |

| NaOH, g | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 |

| Pomegranate peel powder, wt % | 0.1 | 0.2 | 0.3 | ||||||||||

| P. farcta plant powder, wt % | 0.1 | 0.2 | 0.3 | ||||||||||

| Silicon dioxide, wt % | 0.04 | 0.08 | 0.12 | ||||||||||

| Titanium dioxide, wt % | 0.04 | 0.08 | 0.12 | ||||||||||

The powder of pomegranate peel and P. farcta plant as the biodegradable additives were used to fabricate the biodegradable drilling fluids (see Table 3). From adding the P. farcta plant powder into the base drilling fluid at 0.10, 0.20, and 0.30 wt % concentrations, the P. farcta-based drilling fluids (PFMs) were prepared. Additionally, the pomegranate peel powder as the second biodegradable waste material was added into the base drilling fluid at the same concentrations to formulate the pomegranate peel-based drilling fluids (PPMs). These drilling fluids were prepared by mixing the plant powders within the base drilling fluid using a 3-speed Type GM20 Hamilton Beach Commercial mixer for 30 min. Furthermore, to prepare the nanobiodegradable drilling fluids, 0.12 wt % of SiO2 and TiO2 were mixed to the biodegradable drilling fluids (see Table 4). First, the nanoparticles were mixed with water using the UH-IID ultrasonic homogenizer for 2 h. Then, the bentonite, other basic materials for the drilling fluid, and biodegradable waste powders were mixed with the prepared SiO2- and TiO2-based nanofluids using a 3-speed Type GM20 Hamilton Beach Commercial mixer for 1 h.

Table 4. Nano-biodegradable Drilling Fluids Prepared by Mixing Titanium Dioxide and Silicon Dioxide with the Biodegradable Drilling Fluids.

| Nanobiodegradable

drilling fluid |

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S-PPM |

T-PPM |

S-PFM |

T-PFM |

||||||||||

| Drilling fluid component | Drilling fluid | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 |

| Bentonite, g | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Water, mL | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 |

| Soda ash, g | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 |

| Polymer, g | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 |

| NaOH, g | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 |

| Pomegranate peel powder, wt % | 0.1 | 0.2 | 0.3 | 0.1 | 0.2 | 0.3 | |||||||

| P. farcta plant powder, wt % | 0.04 | 0.08 | 0.12 | 0.04 | 0.08 | 0.12 | |||||||

| Silicon dioxide, wt % | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | |||||||

| Titanium dioxide, wt % | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | |||||||

2.4. Rheological Measurements of the Drilling Fluids

The apparent viscosity, plastic viscosity, yield point, and gel strength, which are all rheological properties, of all the prepared drilling fluid samples were measured using the FANN 35 viscometer (see Tables 3 and 4). The cup of the FANN 35 viscometer was filled with the reference drilling fluid, and the apparatus was set up. The gear switch was turned on, and the rotor was rotated at various rotation speeds. Readings at 600 and 300 rpm were noted. These readings help in calculating apparent viscosity, plastic viscosity, and yield point. The apparatus was reworked to measure gel strengths at 10 s and 10 min by reading the highest, or maximum, deflection of the dial before the gel breaks. Both procedures were repeated for all samples mentioned in Tables 3 and 4. Shear stresses and shear rates were also determined from the measured deflections of various speeds of the rotational viscometer. The gel strength of drilling fluids measured at 10 s and 10 min.

To measure the apparent viscosity, plastic viscosity and yield point the below equations were used:

| 1 |

| 2 |

| 3 |

2.5. Filtration Measurements of the Drilling Fluids

The filtration properties including both fluid loss and filter cake were studied for various concentrations of PPP, PFPP, nanosilica (SiO2), nanotitanium (TiO2), and a combination of biodegradable materials and nanoparticles using a Series 300 LPLT Filter Press at 100 psi and room temperature. For all samples shown in Tables 3 and 4, the thickness of the filter cake after 30 min and the fluid loss at different periods from 0 to 30 min were measured. A filter paper was placed in the right place in the cell of the Series 300 LPLT Filter Press correctly, and the reference drilling fluid was poured into the filter cell. A graduated cylinder was placed under the filtrate tube, and the filter press was set up for the tests. As the apparatus was all set up, timing was initiated and the test was started. The test was allowed to continue for 30 min. The amount of filtrate in the graduated cylinder was read and noted at various periods during the 30 min. The filter cake thickness was then measured. This procedure was repeated for all samples mentioned in Tables 3 and 4.

3. Results and Discussion

3.1. Rheological Properties

In this section, the rheological measurements including the plastic viscosity (μp), apparent viscosity (μa), yield point and gel strength of the base drilling fluid, biodegradable drilling fluid, nanodrilling fluid, and nanobiodegradable drilling fluid are presented and discussed as shown in Table 5. The measurements included plastic viscosity, apparent viscosity, yield point, and gel strengths at 10 s and 10 min. As can be seen, the plastic and apparent viscosities of the base sample were 19.5 and 7 cP, respectively, while the yield point was 10.5 lb/100 ft2 and 10 s and 10 min gel strengths were 15 and 24 lb/100 ft2, respectively.

Table 5. Measured Vales of the Plastic Viscosity (μp), Apparent Viscosity (μa), Yield Point and Gel Strength (10 s and 10 min) of the Base Drilling Fluid, Biodegradable Drilling Fluids, Nanodrilling Fluids and Nano-biodegradable Drilling Fluids.

| Gel strength,

lb/100 ft2 |

||||||

|---|---|---|---|---|---|---|

| Drilling fluid | Sample | YP (Ib/100 ft2) | μp (cP) | μa (cP) | Gelinitial | Gelfinal |

| Base sample | BM | 10.5 | 19.5 | 7 | 15 | 24 |

| Biodegradable drilling fluids | PPM_1 | 7.5 | 13.5 | 7 | 10 | 20 |

| PPM_2 | 8 | 12.5 | 6 | 7 | 18 | |

| PPM_3 | 5.5 | 14.5 | 7 | 9 | 24 | |

| PFM_1 | 7.5 | 16 | 8 | 16 | 41 | |

| PFM_2 | 7 | 14.5 | 7 | 14 | 38 | |

| PFM_3 | 5 | 15 | 8 | 11 | 29 | |

| Nanodrilling fluids | SNF_1 | 5.5 | 16.75 | 11 | 22 | 47 |

| SNF_2 | 7 | 18 | 8 | 9 | 25 | |

| SNF_3 | 5 | 14.5 | 7 | 9 | 22 | |

| TNF_1 | 8.5 | 15.5 | 8 | 18 | 41 | |

| TNF_2 | 7.5 | 16 | 7 | 19 | 39 | |

| TNF_3 | 7 | 14 | 6 | 15 | 36 | |

| Silica-biodegradable drilling fluids | PP_SNF_1 | 5.75 | 11.5 | 6 | 6 | 16 |

| PP_SNF_2 | 10 | 12 | 5 | 8 | 20 | |

| PP_SNF_3 | 8.5 | 11 | 6 | 9 | 24 | |

| PF_SNF_1 | 6.5 | 13.5 | 6 | 16 | 32 | |

| PF_SNF_2 | 6.5 | 13 | 5 | 10 | 30 | |

| PF_SNF_2 | 7.5 | 12.5 | 7 | 9 | 25 | |

| Titanium-biodegradable drilling fluids | PP_TNF_1 | 8 | 12.5 | 5 | 14 | 24 |

| PP_TNF_2 | 7.5 | 13 | 6 | 10 | 21 | |

| PP_TNF_3 | 7 | 11 | 8 | 9 | 19 | |

| PF_TNF_1 | 9 | 14.5 | 7 | 17 | 34 | |

| PF_TNF_2 | 7.5 | 13.5 | 6 | 14 | 33 | |

| PF_TNF_3 | 8 | 13 | 6 | 11 | 30 | |

Biodegradable Drilling Fluid

The rheological properties of the drilling fluid with 0.1 wt % of pomegranate peel powder (PPM_1) were measured and it was found that the plastic viscosity and yield point are 13.5 cP and 6.5 lb/100 ft2, respectively. However, the apparent viscosity remained the same as what achieved with the base sample. The gel strength at 10 s and 10 min were also found to be 10 and 20 lb/100 ft2, respectively. As the concentration of the PPP increased to 0.2 wt %, the plastic and apparent viscosities and gel strengths at 10 s and 10 min were reduced. However, the yield point remained the same in comparison to the biodegradable drilling fluid with 0.1 wt % of PPP. The gel strength at 10 min and plastic viscosity stayed the same, but the other properties decreased. When 0.3 wt % PPP was added to the drilling fluid, plastic and apparent viscosities, yield point, and gel strengths at 10 s and 10 min were increased compared with the formulated base drilling fluid with 0.2 wt % PPP. The gel strength at 10 s was found to be 9 lb/100ft2, which is the same result that Al-Saba et al.6 obtained (see Figures 3a and 4a).

Figure 3.

Results of the gel strength at 10 s and 10 min of the biodegradable drilling fluids and nanodrilling fluids: (a) pomegranate peel powder, (b) P. farcta plant powder, (c) SiO2, and (d) TiO2.

Figure 4.

Results of the plastic viscosity (μp), apparent viscosity (μa), and yield point of the biodegradable drilling fluids and nanodrilling fluids: (a) pomegranate peel powder, (b) P. farcta plant powder, (c) SiO2, and (d) TiO2.

In addition, Figures 3b and 4b illustrate the rheological measurements of the biodegradable drilling fluids prepared by mixing P. farcta plant powder (PFPP) with the base drilling fluid at three different concentrations. With the addition of 0.05, 0.1, and 0.2 wt % of PFPP, the plastic viscosity and gel strength at 10 min were reduced significantly, whereas the apparent viscosity, yield point and gel strength at 10 s increased surprisingly. The plastic viscosity and 10 min gel strength were reduced to be 8 cP and 16 lb/100 ft2, respectively, and apparent viscosity, yield point and 10 s gel strength were increased to 11 cP, 16 and 41 lb/100 ft2, respectively, as 0.05 wt % PFPP were added to the drilling fluid as shown in Figure 4b.

Nanodrilling Fluid

As the nanosilica was added to the base drilling fluid, the plastic viscosity and yield point decreased. It was noticed that as 0.04 and 0.08 wt % nanosilica were added to the drilling fluid, the apparent viscosity and gel strength at 10 min were increased as shown in Figures 3c and 4c. Reductions in all of the measured rheological properties are perceived apart from the apparent viscosity, which kept its initial value. The test results proved that as 0.04, 0.08, and 0.12 wt % nanotitanium were mixed with the drilling fluid the plastic viscosity and gel strengths were reduced. On the other hand, as the three different concentrations of the TiO2 NP were added to the drilling fluid, the yield point increased. The behavior of the change in the apparent viscosity that was produced by the addition of nanotitanium was different. When 0.04 wt % NT (nanotitanium) was used, the apparent viscosity maintained its value; when 0.08 wt % NT was used, the apparent viscosity increased, while the apparent viscosity was reduced when 0.12 wt % NT was added to the base drilling fluid (see Figures 3d and 4d). The changes in viscosities obtained using different concentrations of nanotitanium in our work can be verified by the results gained by Wrobel.19

Nanobiodegradable Drilling Fluid

The results of the rheological measurements of the biodegradable drilling fluids under the influence of SiO2 and TiO2 nanoparticles at the optimum concentration are shown in Figures 5 and 8. The values of all measured rheological properties of the prepared samples of drilling fluid using the optimum concentration of nanosilica and various concentrations of PPP, 0.1, 0.2, and 0.3 wt %, reduced in comparison to the reference fluid except the 10 min gel strength when 0.3 wt % of nanosilica was used in which it stayed 24 lb/100 ft2 as shown in Figures 5a and 8a. Additionally, it was found that as the optimum concentration of SiO2 nanoparticles are mixed with various concentrations of PFPP and added to the base drilling fluid, plastic viscosity and yield point are reduced, whereas gel strengths at 10 min were increased (see Figures 5b and 6b). This formulation had a different behavior when applied to the apparent viscosity. To be clear, as the optimum nanosilica concentration and 0.2% PFPP (by weight) were used to formulate a drilling fluid sample, the apparent viscosity kept its value. However, as lower concentrations were used, the apparent viscosity started to decrease (see Figures 5b and 6b).

Figure 5.

Results of the gel strength at 10 s and 10 min of the nanobiodegradable drilling fluids: (a) optimum of SiO2 with pomegranate peel powder, (b) optimum of SiO2 with P. farcta plant powder, (c) optimum of TiO2 with pomegranate peel powder, and (d) optimum of TiO2 with P. farcta plant powder.

Figure 8.

Viscosity as functions of shear rates for of the drilling fluids with nanosilica, pomegranate peel powder, nanotitanium, and P. farcta plant powder.

Figure 6.

Results of the plastic viscosity (μp), apparent viscosity (μa), and yield point of the nanobiodegradable drilling fluids: (a) optimum of SiO2 with pomegranate peel powder, (b) optimum of SiO2 with P. farcta plant powder, c) optimum of TiO2 with pomegranate peel powder, and d) optimum of TiO2 with P. farcta plant powder.

In Figures 5c and 6c, it is shown that when the optimal concentration of nanotitanium and 0.1 and 0.2 wt % PPP were mixed with the base sample of drilling fluid, all the rheological properties experienced reductions in their values apart from the gel strength at 10 min which remained 24 lb/100 ft2 when 0.2 wt % PPP were used. Likewise, when 0.3 wt % PPP was used with an optimum concentration of nanotitanium to formulate a drilling fluid, reductions were felt in the rheological properties expect in apparent viscosity, which recorded a higher value. Moreover, as 0.1 and 0.3 wt % PFPP were used with optimum concentration of nanotitanium, apparent viscosity and 10 s gel strengths were lowered as well. However, when a PFPP of 0.05 wt % was mixed with an optimum concentration of TiO2 nanoparticles, the apparent viscosity did not change, on the other hand, the gel strength at 10 s increased a little compared to that of the base fluid (see Figures 5d and 6d).

3.3. Shear Stress and Shear Rate Relationship

The relationship between the shear stresses and shear rates for the prepared drilling fluids including the base sample, biodegradable drilling fluids, nanodrilling fluids, and nanobiodegradable drilling fluids is depicted in Figure 7. As can be seen, the relationship between the shear stress and shear rate is dependent on the composition of the drilling fluid as it changes from a drilling fluid to another one. Starting from the base drilling fluid, the maximum shear stress can be seen as shear rate increases from 0 to 500–1. According to the Bingham-plastic model, the shear stress and shear rate curve are defined as the plastic viscosity and the intersect of the Y axis is the yield point. For the base sample, a high yield point was observed at 120 dyn/cm2. The drilling fluids prepared from the pomegranate peel powder with or without the presence of the nanoparticles presented the lowest relationship of the shear stress and shear rate and the yield point.20 The minimum yield point of 28 dyn/cm2 was achieved with the biodegradable drilling fluid prepared from 0.3 wt % of PPP and nanobiodegradable prepared from missing the optimum concentrations of TiO2 and SiO2 with the PPP. Other curves of the shear stress and shear rate relationships from other drilling fluids ranged between the mentioned-above ranges of yield points from 28 to 120 dyn/cm2. Even though, irregular values were noticed at the shear rate between 300 to 400–1 for all the used drilling fluids except the base sample.

Figure 7.

Shear stress versus shear rate behavior of the drilling fluids with nanosilica, pomegranate peel powder, nanotitanium, and P. farcta plant powder.

In addition, Figure 8 shows the shear rate viscosity of the base sample, biodegradable drilling fluids, nanodrilling fluids and nanobiodegradable drilling fluids. The viscosity is reduced with an increase in the shear rate from 170 to 1000–1 for all used samples of drilling fluids. This confirms the thinning behavior of the drilling fluids which is necessary to provide a good gelation under static conditions and a smooth flow with the minimum pressure loss during caring cutting to the surface.20−22 The nanobiodegradable drilling fluids (PP_SNF, PP_TNF, PF_SNF, and PF_TNF) prepared from mixing PPP, PSP, TiO2, and SiO2 showed the best thinning performance. The minimum shear rate viscosity of 14 cP was obtained with the PF_TNF_2 at 1000–1 shear rate, while the maximum shear rate viscosity of 420 cP was determined at shear rate of 170–1 with the base sample of the drilling fluid.

3.4. Filtration Properties

The filtration characteristics, both fluid loss volume and filter cake thickness, of the water-based drilling fluids modified with nanoparticles and biodegradable materials were studied and determined. Figure 9 illustrates the filtration rate of the base drilling fluid, biodegradable drilling fluids, nanodrilling fluids, and nanobiodegradable drilling fluids during 30 min. As can be seen, the base drilling fluid had the highest filtration rate which increases during the time to 11.6 mL at 30 min. Generally, the biodegradable drilling fluids prepared from pomegranate peel and local P. farcta plant powders showed the best performance in reducing the filtration rate due to creating sufficient filter cakes which are impermeable while the nanodrilling fluids prepared from the adding SiO2 and TiO2 nanoparticles into the base drilling fluid were not effective in decreasing the filtration rate to favorable rates. In addition, nanobiodegradable drilling fluids performed well in sealing the permeable filters that represent the wall of the borehole due to loss of effective filter cakes. The minimum filtration rate of 7.9 mL at 30 min was obtained with the biodegradable drilling fluid prepared by mixing 0.3 wt % pomegranate peel powder with the base drilling fluid.

Figure 9.

Results of filtration rate of the base drilling fluid (BM), biodegradable and nanodrilling fluids (PPM, PFM, SNF, and TNF) and nanobiodegradable drilling fluids (PP_SNF, PP_TNF, PF_SNF, and PF_TNF).

Figure 10 demonstrates the filtration rates of the base drilling fluid, biodegradable drilling fluids, and nanodrilling fluids at 30 min of the filtration measurement test. The base drilling fluid had the highest rate of filtration, 11.6 mL, due to failing the creating of the filter cake. As is clear, the biodegradable drilling fluids prepared from PPP and PFP at different concentrations of 0.1–0.3 wt % demonstrated the best performance compared with drilling fluid, nanodrilling fluids, and nanobiodegradable drilling fluids (see Figure 10b). When 0.3 wt % of PPM was added into the base drilling fluid, the filtration rate was reduced by 32% from 11.6 to 7.9 cc. PFM_3 drilling fluid enabled to drop the filtration rate to 9.6 mL at 0.3 wt %. However, the formulated drilling fluid with an optimum concentration of 0.12 wt % of nanotitanium recorded a fluid loss volume of 11 mL. As 0.08% (by weight) nanosilica was added to the base drilling fluid, a filtration rate of 9.7 mL was recorded. Despite the fact that Ragab and Noah8 used 20–30 wt % nanosilica and a fluid loss reduction of 56% was obtained, this can validate our results of more than 16% reduction in fluid loss volume using only 0.08 wt % SiO2 (see Figure 10a).

Figure 10.

Measured filtration rates at 30 min of the filtration experiment of the base drilling fluid (BM): (a) biodegradable and nano drilling fluids and (b) nanobiodegradable drilling fluids.

During the investigation of the drilling fluid with the optimum concentration of nanoparticles mixed with the PFP and PPP biodegradable drilling fluids. The filtration rates of the reference drilling fluid and combinations of biodegradable material- and NPs-modified drilling fluids are illustrated in Figure 10b. Results have shown that the addition of 0.2 wt % PFP to the nanosilica reduced the fluid loss by 12% in comparison with the base drilling fluid. Moreover, the addition of 0.3 wt % of PPP to the nanosilica decreased the fluid loss by 75% compared with the base drilling fluid. In addition, combination of nanotitanium with PFP and PPP, respectively, are studied. The results show that the addition of 0.2 wt % PFP to nanotitanium dropped the fluid loss by as much as 12% in comparison with the base drilling fluid, while the most efficient result used 0.3 wt % of PPP in addition to nanotitanium which decreased the fluid loss by 25.8% (8.6 mL) (see Figure 10b). As is shown in Figure 10a,b, the biodegradable drilling fluid prepared from mixing 0.3 wt % of pomegranate peel powder within the base drilling fluid was the most effective sample in terms of the fluid loss reduction that recorded 7.9 mL of filtration compared with the other used drilling fluids.27

The thickness of the filter cake as the second crucial parameter of the filtration was also measured for all prepared samples of the drilling fluids including base drilling fluid, biodegradable drilling fluids, and nanobiodegradable drilling fluids at different concentrations. Figure 11 shows the recorded values of fluid loss taken from the filtration measurement. As can be seen, the thickest filter cake achieved when the base drilling fluid in the presence of the biodegradable and nanoparticles used was 4 mm. On the other hand, the cake thickness was reduced to 2 and 1.5 when 0.3 wt % of the pomegranate peel and P. farcta plant powders were added into the base drilling fluid.23,24 As can be seen in Figure 11a, the filter cake of the drilling fluid became thinner with an increasing concentration of the biodegradable materials that is consistent with the experimental outcomes reported by Okon et al.10 By adding 0.3 wt % PPP, tremendous reduction in the filter cake thickness by 50% was recorded when compared to those of the base drilling fluid. When 0.2 wt % PFPP was used, the cake thickness was reduced by 25% in comparison to the base mud. Even though the nanoparticles were as effective as the biodegradable materials, SiO2 and TiO2 nanoparticles (NPs) built a thinner cake thickness compared with the base drilling fluid. Their impact on reducing the thickness of the filter cake was increased by increasing the concentration of the NPs.9 As is clear, the silica NPs had a stronger impact on the lowering the cake thickness that was by 50% compared with the titanium NPs (see Figure 11a).

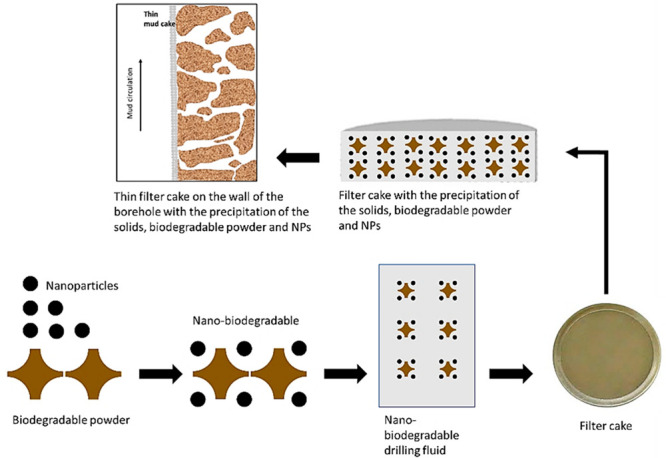

Figure 11.

Measured thicknesses (mm) of filter cakes of the base-drilling fluid (BM): (a) biodegradable and nanodrilling fluids and (b) nanobiodegradable drilling fluids.

Figure 11b shows the measured values of the cake thicknesses of the drilling fluids under the influence of the biodegradable and nanoparticles. Mixing the SiO2 at the optimum concentration within the biodegradable drilling fluids prepared from PPP and PFP at different concentrations reduced the thickness of the drilling fluid by 75% from 4 to 1 mm. As can be seen, the silica–pomegranate peel powder and silica–P. farcta plant powder nanobiodegradable drilling fluids had a larger impact on developing the thinner filter cake compared with pomegranate peel powder biodegradable and nanodrilling fluids; PP-SNF and PF-SNF nanodrilling fluids enabled a decrease in the cake thickness with an increase in concentration (see Figure 11b). Moreover, the addition of the TiO2 NPs into the PP-biodegradable drilling fluid at 0.3 wt % enabled production of the thinnest filter cake at 0.8 mm, with a reduction of 80% compared with the base drilling fluid and 60% in comparison with the SiO2-nano and PP-biodegradable drilling fluids. The mechanism of the influence of the nanoparticles on the filtration properties of biodegradable drilling fluids as shown in Figure 12. As can be seen, when the nanobiodegradable drilling fluid flows through the borehole (or in the filtration sample cell), the biodegradable power precipitates on the filter paper (wall of the borehole) and nanoparticles also sediment in combination with the biodegradable powder. This combined precipitation of the biodegradable and nanomaterials on the filter paper prevent higher fluid loss due to sealing the permeability of the wall of borehole quickly. Thus, the thinner cake thickness can be developed, which is good in terms of drilling a wider borehole. In order to have a better vision on the precipitation of novel and environmentally friendly materials used in this study, the SEM images of the filter cakes of the developed drilling fluids at the optimum concentrations, such as base sample drilling fluid, biodegradable drilling fluids, nanobiodegradable drilling fluids, and nanobiodegradable drilling fluids, are shown in Figure 13. A clear difference between all the images can be noticed in terms of the materials precipitated on the filter cakes obtained at 30 min of the filtration press. The surface of the filter cake developed from using the base drilling fluid (BM) is smooth. While, the presence of the pomegranate peel and P. farcta plant powders in the biodegradable drilling fluids (PFM and PPM) with the large particles are observed clearly as shown in Figure 13. The silica and titanium nanoparticles can also been seen on the surface of filter cakes created when nanodrilling and nanobiodegradable drilling fluids are used.

Figure 12.

Schematic diagram illustrates the mechanism of precipitation of the biodegradable and nanomaterials on the wall of the borehole.

Figure 13.

SEM images of filter cakes developed during the filtration experimental test of the drilling fluid, biodegradable drilling fluids, nanodrilling drilling fluids, and nano-biodegradable drilling fluids.

4. Conclusions

The main goal of this study was to formulate a drilling fluid using nanoparticles (as nanodrilling fluids), biodegradable waste materials (biodegradable drilling fluids), and a combination of both of them as nanobiodegradable drilling fluids to achieve better filtration and rheological properties. During the investigation period, the optimum concentrations of nanosilica and nanotitanium were discovered to be 0.08 and 0.12 wt %, respectively, based on achieving the lowest filtration rate. The results reveal that as the nanoparticles were mixed with various concentrations of the biodegradable materials, optimum concentrations in weight percentage of the combination were 0.2 for NFS and NFT and 0.3 for NPT and NPS. Using the nanoparticles and biodegradable materials under study in any concentration resulted in reductions in the filtration rates and filter cake thickness. The results show that the optimum results were acquired when pomegranate peel powder of 0.3% (by weight) was added to the base mud and fluid loss volume was reduced to 7.9 mL. Additionally, an optimum filter cake thickness of 1 mm was achieved when 0.3 wt % PPP was mixed with an optimum concentration of nanotitanium as well as when an optimum concentration of nanotitanium was mixed with 0.3 wt % PPP and 0.2 wt % PFPP.

Acknowledgments

The authors acknowledge Soran University for its support and funding this study through the research grant.

The authors declare no competing financial interest.

References

- Nmegbue G. C.; Bari-Agara B. Evaluation of corn cob cellulose and its suitability for drilling mud formulation. Int. J. Eng. Res. Appl. 2014, 4 (5), 112–117. [Google Scholar]

- Wagle V.; Kalgaonkar R.; Al-Yami A. S.. Nanoparticle-Based Chemical Treatment for Preventing Loss Circulation. In SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition. S. Petrol. Eng. 2018. 10.1115/1.4049600 [DOI] [Google Scholar]

- Nutskova M.; Rudyaeva E. Substantiation and development of mixtures for quick liquidation of drilling fluid loss of circulation. Constr. oil gas wells land sea 2018, (9), 15–20. 10.30713/0130-3872-2018-9-15-20. [DOI] [Google Scholar]

- Iscan A. G.; Kok M. V.; Bagci A. S. Permeability reduction due to formation damage by drilling fluids. Energy Sources 2007, 29 (9), 851–859. 10.1080/00908310600713958. [DOI] [Google Scholar]

- Al-Yasiri M. S.; Al-Sallami W. T. How the drilling fluids can be made more efficient by using nanomaterials. American J. Nano Res. Appl. 2015, 3 (3), 41–45. 10.11648/j.nano.20150303.12. [DOI] [Google Scholar]

- Al-Saba M. T.; Amadi K. W.; Al-Hadramy K. O.; Al Dushaishi M. F.; Al-Hameedi A.; Alkinani H.. Experimental Investigation of Bio-Degradable Environmentally Friendly Drilling Fluid Additives Generated from Waste. SPE International Conference and Exhibition on Health, Safety, Security, Environment and Social Responsibility; Society of Petroleum Engineers, 2018.

- Irawan S.; Azmi A. Z. A.; Saaid I. M.. Corncob and sugar cane waste as a viscovifer in hydrocarbon drilling fluid. Numerical and model test results for truss spar platform 2009, 9. [Google Scholar]

- Ragab A. S.; Noah A. Reduction of formation damage and fluid loss using nano-sized silica drilling fluids. Petrol. Technol. Dev. 2014, 2, 75–88. [Google Scholar]

- Ismail A. R. Improve performance of water-based drilling fluids. Sriwijaya International Seminar on Energy-Environmental Science and Technology 2014, 1 (1), 43–47. [Google Scholar]

- Okon A. N.; Udoh F. D.; Bassey P. G.. Evaluation of rice husk as fluid loss control additive in water-based drilling mud. SPE Nigeria Annual International Conference and Exhibition; Society of Petroleum Engineers, 2014. [Google Scholar]

- Hossain M. E.; Wajheeuddin M. The use of grass as an environmentally friendly additive in water-based drilling fluids. Petrol. Sci. 2016, 13 (2), 292–303. 10.1007/s12182-016-0083-8. [DOI] [Google Scholar]

- Dagde K.; Nmegbu G. C. J.. Drilling fluid formulation using cellulose generated from groundnut husk. Int. J. Adv. Res. Technol. 2014, 3( (6), ). [Google Scholar]

- Amanullah M. D.; Ramasamy J.; Thuwaini T.; Alsubaie M.; Fuwaires O. M.. Date seed powder as a fluid loss additive for drilling fluids WO2016172287A1, 2016

- Sharma V. P.; Mahto V.. Studies on less expansive environmentally safe polymers for development of water based drilling fluids. SPE Europec featured at 81st EAGE Conference and Exhibition, 2006.

- Davoodi S.; SA A. R.; Jamshidi S.; Jahromi A. F. A novel field applicable mud formula with enhanced fluid loss properties in High Pressure-High Temperature well condition containing pistachio shell powder. J. Petrol. Scie. Eng. 2018, 162, 378–385. 10.1016/j.petrol.2017.12.059. [DOI] [Google Scholar]

- Vryzas Z.; Kelessidis V. C. Nano-based drilling fluids: A review. Energies 2017, 10 (4), 540. 10.3390/en10040540. [DOI] [Google Scholar]

- Mahmoud O.; Nasr-El-Din H. A.; Vryzas Z.; Kelessidis V. C. Nanoparticle-based drilling fluids for minimizing formation damage in HP/HT applications. Int. Petrol. Technol. Conf. 2016, 10.2118/178949-ms. [DOI] [Google Scholar]

- Ali J. A.; Kolo K.; Sajadi S. M.; Hamad K. H.; Salman R.; Wanli M.; Hama S. M. Modification of rheological and filtration characteristics of water-based mud for drilling oil and gas wells using green SiO2@ZnO@Xanthan nanocomposite. IET Nanobiotechnology 2019, 13 (7), 748–755. 10.1049/iet-nbt.2018.5205. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wrobel S.Development of an improved Nanoparticle-modified Water Based Drilling Fluid. Master’s thesis. University of Stavenger, 2016. [Google Scholar]

- Wang Z.; Wu Y.; Luo P.; Tian Y.; Lin Y.; Guo Q. Poly (sodium P-styrene sulfonate) modified Fe3O4 nanoparticles as effective additives in water-based drilling fluids. J. Petrol. Scie. Eng. 2018, 165, 786–797. 10.1016/j.petrol.2018.03.001. [DOI] [Google Scholar]

- Ali J. A.; Hamadamin A. B.; Ahmed S. M.; Mahmood B. S.; Sajadi S. M.; Manshad A. K. Synergistic effect of Nanoinhibitive drilling fluid on the shale swelling performance at high temperature and high pressure. Energy Fuels 2022, 36 (4), 1996–2006. 10.1021/acs.energyfuels.1c03804. [DOI] [Google Scholar]

- Ali J. A.; Kalhury A. M.; Sabir A. N.; Ahmed R. N.; Ali N. H.; Abdullah A. D. A state-of-the-art review of the application of nanotechnology in the oil and gas industry with a focus on drilling engineering. J. Petrol. Scie. Eng. 2020, 191, 107118. 10.1016/j.petrol.2020.107118. [DOI] [Google Scholar]

- Xinfeng D.; Yongzhe Z.. Study on drilling and completion techniques of horizontal well for coalbed methane in Binchang mining area. 4th Electronic System-Integration Technology Conference, 2012.

- Yang X.; Cai J.; Jiang G.; Zhang Y.; Shi Y.; Chen S.; Li H. Modeling of nanoparticle fluid microscopic plugging effect on horizontal and vertical wellbore of shale gas. Energy 2022, 239, 122130. 10.1016/j.energy.2021.122130. [DOI] [Google Scholar]

- Kalfatovic M. R.; Costantino G. The biodiversity heritage library: Empowering discovery through free access to biodiversity knowledge. KULA: Knowledge Creation, Dissemination, and Preservation Studies 2018, 2, 17. 10.5334/kula.41. [DOI] [Google Scholar]

- Shahbazi B.; Feyzmand S.; Jafari F.; Ghiasvand N.; Bahrami G.; Fattahi A.; Shokoohinia Y. Antidiabetic potential of Prosopis farcta roots: In vitro pancreatic beta cell protection, enhancement of glucose consumption, and bioassay-guided fractionation. Evidence-Based Compl. Alt. Med. 2020, 2020, 1–9. 10.1155/2020/8048273. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lyu S.; Wang S.; Chen X.; Shah S.; Li R.; Xiao Y.; Gu Y. Experimental study of a degradable polymer drilling fluid system for coalbed methane well. J. Petrol. Scie. Eng. 2019, 178, 678–690. 10.1016/j.petrol.2019.03.065. [DOI] [Google Scholar]