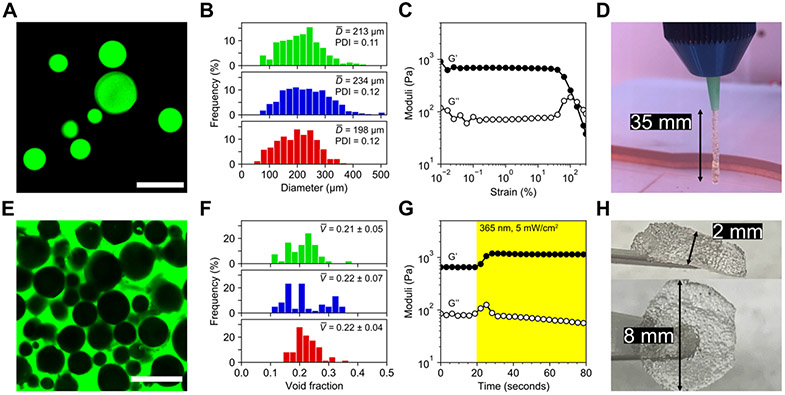

Figure 2.

Characterization of granular hydrogels as an extrudable bioink. A) Fluorescein-tagged microgels were imaged and sized. Scale bar = 500 μm. B) Size distributions for amide (top), ester (middle), and thioester (bottom) microgels did not vary significantly with material chemistry. Average diameters ranged ~200-230 μm and were relatively monodisperse with PDIs <0.15. Bin widths are ~20 μm. C) Jammed microgels exhibited strain yielding behavior on oscillatory rheological testing near 100% strain, demonstrating printability. D) Microgels were printed by extrusion through an 18 gauge conical tip. Hanging filament tests indicated strong stiction forces between microgels, conferring short-term stability to printed constructs before secondary photocrosslinking. E) Printed scaffold voids were filled with fluorescent solution and imaged for analysis. Scale bar = 500 μm. F) Void fraction analysis revealed similar packing between amide (top), ester (middle), and thioester (bottom) microgels, with average post-printing void fractions near 0.2. Bin widths are ~0.02. G) Post-printing irradiation with mild UV light was used to crosslink network-tethered norbornene groups with free multi-arm PEG thiol, resulting in a ~2-fold increase in scaffold storage modulus, from ~600 Pa to >1 kPa, within seconds of light exposure. H) Annealing by secondary photocrosslinking afforded large, easy-to-handle scaffolds composed of tens of thousands of microgels.