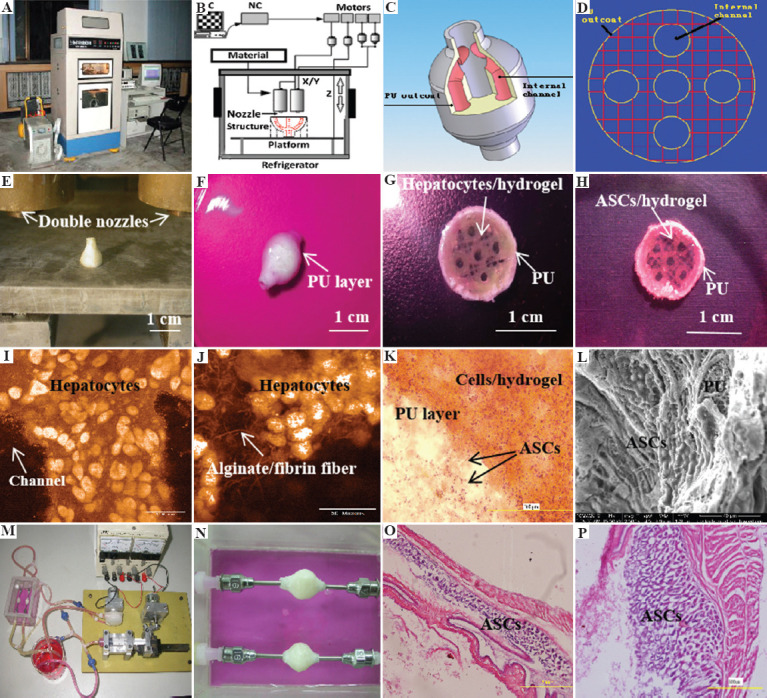

Figure 8.

A large scale-up 3D-printed complex organ with vascularized liver tissue constructed through the double-nozzle 3D bioprinter created at Prof. Wang’s laboratory in Tsinghua University: (A) The double-nozzle 3D bioprinter, (B) a computer-aided design (CAD) model containing a branched vascular network, (C) a CAD model containing the branched vascular network, (D) a cross-section of the CAD model containing five sub-branched channels, (E) working platform of the 3D bioprinter containing two nozzles, (F) an ellipse sample containing both a cell-laden natural hydrogel and a synthetic polyurethane (PU) overcoat, (G) several layers of the ellipse sample in the middle section containing a hepatocyte-laden gelatin-based hydrogel and a PU overcoat, (H) several layers of the ellipse sample in the middle section containing an adipose-derived stem cell (ASC)-laden gelatin-based hydrogel and a PU overcoat, (I) hepatocytes encapsulated in the gelatin-based hydrogel, (J) a magnified photo of (I) showing the alginate/fibrin fibers around the hepatocytes, (K) ASCs encapsulated in the gelatin-based hydrogel growing into the micropores of the PU layer, (L) ASCs on the inner surface of the branched channels, (M) pulsatile culture of two ellipse samples, (N) two samples cultured in the bioreactor, (O) static culture of the ASCs encapsulated in the gelatin-based hydrogel, (P) pulsatile culture of the ASCs encapsulated in the gelatin-based hydrogel. Reprinted from Materials Science and Engineering: C, Vol 33, Issue 6, Huang Y, He K, Wang X, Rapid prototyping of a hybrid hierarchical polyurethane-cell/hydrogel construct for regenerative medicine, 3220-3229., Copyright (2013), with permission from Elsevier.