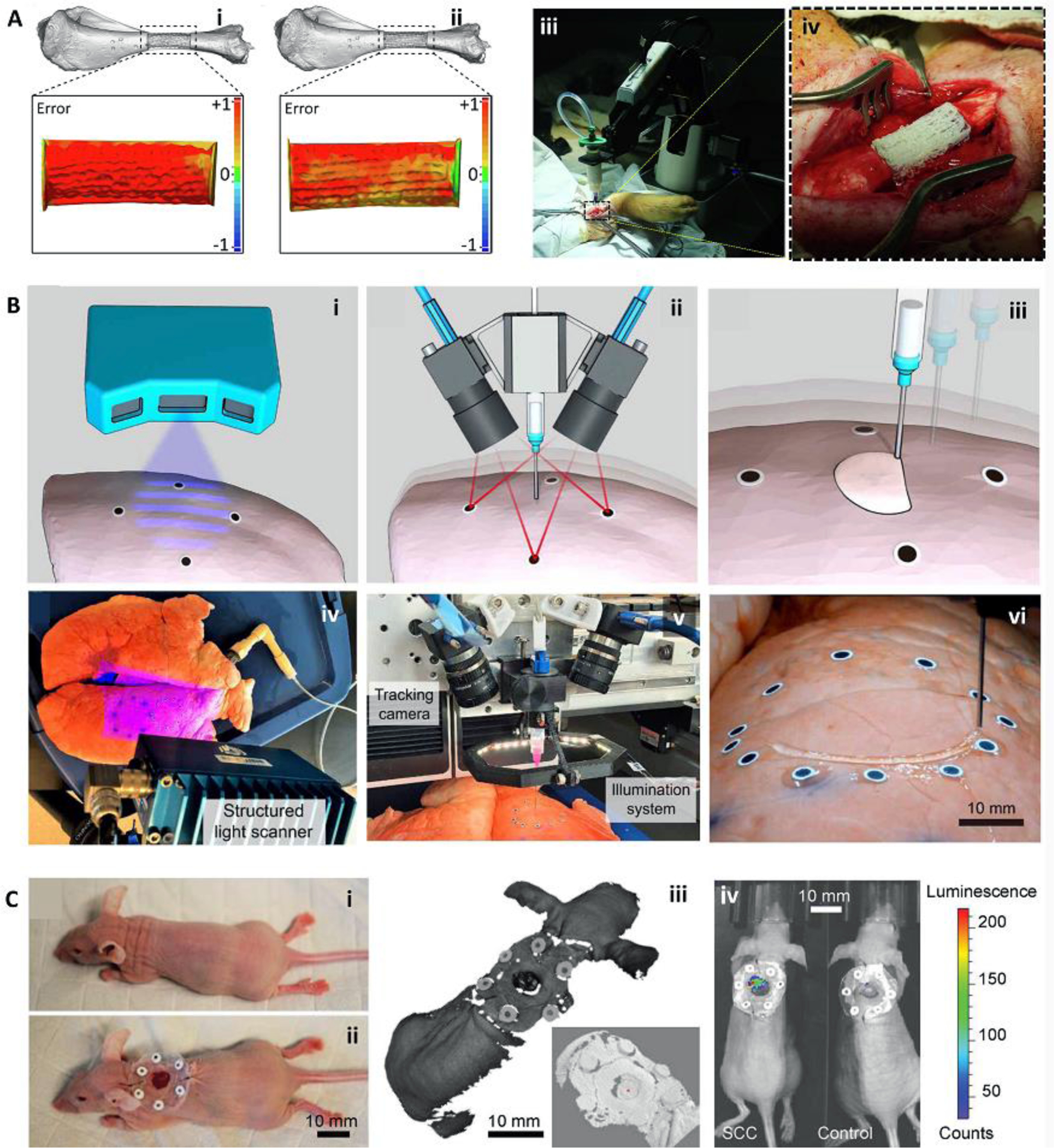

Figure 1.

Bioprinting integrated with scanning for minimizing errors during in situ bioprinting. (A) Error compensation before the main bioprinting procedure. Bioprinting was performed on a prototype defect model (i), the accumulative error of printing was detected with a scanner and compensated in the new printing process to reduce the error (ii). The corrected G-code was then used for in situ bioprinting of the bioink in a porcine long segmental bone defect (iii, iv). (B) Adaptive in situ printing using a closed-loop integrated scanning and printing system. The process of in situ printing on a breathing lung is shown schematically (i-iii), with the images of the actual setup (iv-vi). The surface of the lung was scanned (i, iv) and tracked in real-time using the fiducial guiding points (ii, v) while closed-loop feedback from the tracking module enabled printing on the moving lung (iii, vi). (C) Adaptive bioprinting for regeneration of the skin defects in live animals. Due to the movement of the body under anesthesia, in situ printing strategies can be improved by using adaptive bioprinting to compensate for movements during printing. A murine model (i) was used by the creation of a full-thickness wound and placement of fiducial markers (ii). The surface was scanned (iii, zoom-in inset) and a bioink was printed inside the defect. After 4 hr, the presence of live cells was confirmed using bioluminescence imaging (iv). Adapted with permission from Elsevier [28] (A), American Association for the Advancement of Science [27] (B), and Wiley [26] (C).