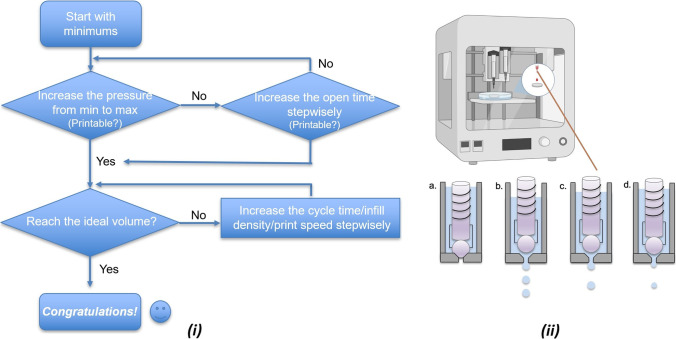

Fig. 1.

(i) Decision flow chart for selecting print parameters.; (ii) Schematic diagram of the working principle of the DoD droplet deposition printing technology. Before printing, the system is closed (a); after printing, the valve is opened (b, c, d) and the pressurized fluid can flow. Open time and cycle time determine how long and how often the valve opens, changing the droplet size and frequency of droplet discharge. For example, if only the cycle time is reduced, the frequency of droplet discharge decreases while the droplet size remains the same (b, c). If the open time is reduced while the cycle time remains the same, it will only reduce the droplet size (c, d). [Figure adapted from manufacturer’s respective Printhead User Manual Page 44].