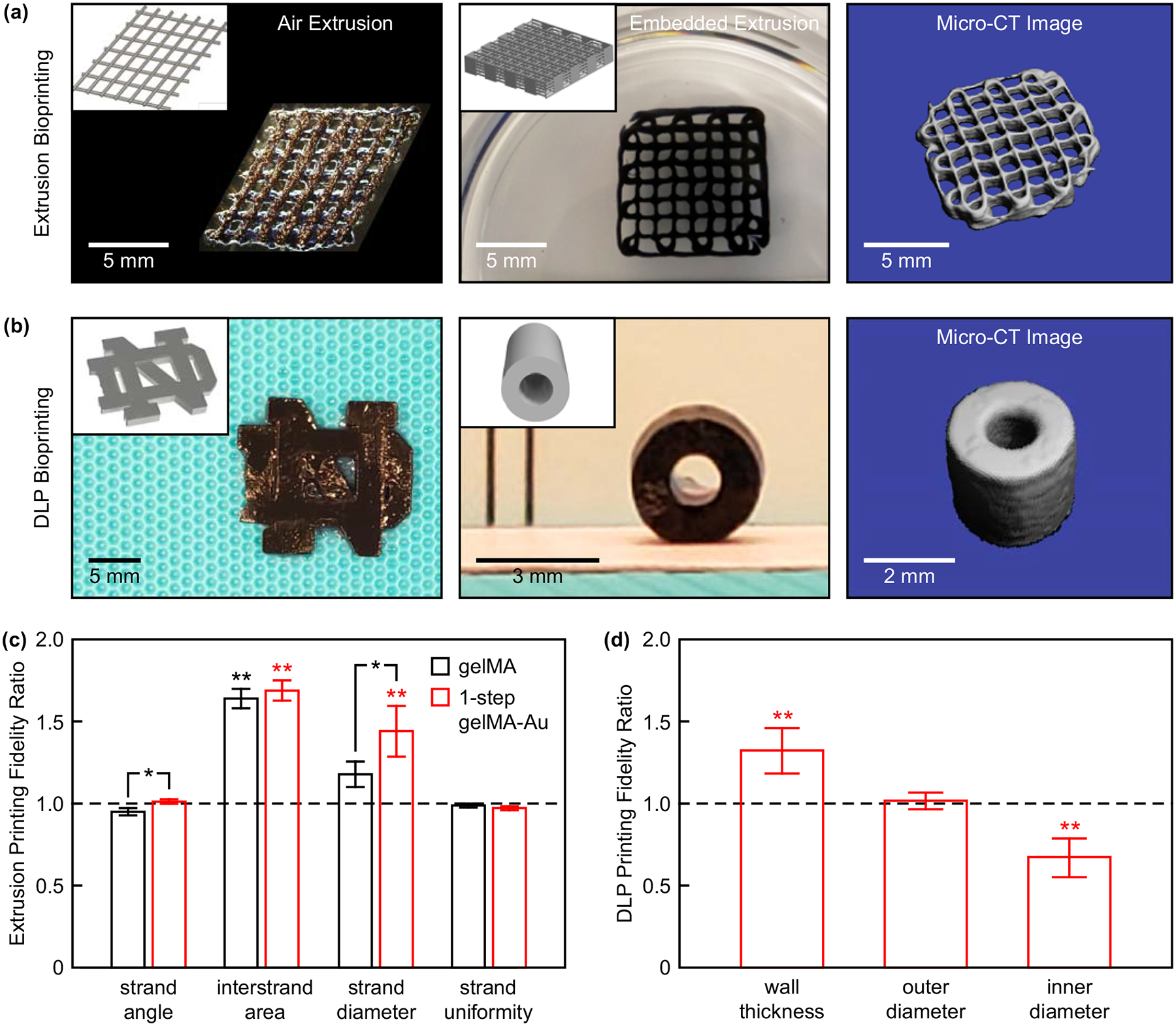

Figure 5. 3D bioprinting of 1-step gelMA-Au NP hydrogel constructs.

(a) A two-layer lattice scaffold printed by air extrusion and 10-layer lattice scaffold printed by embedded extrusion. (b) The University of Notre Dame logo (left) and a cylindrical tube mimicking a blood vessel printed by DLP bioprinting. Insets show corresponding CAD models. Segmented micro-CT image reconstructions of the 10-layer lattice scaffold and cylindrical tube show feasibility of non-invasive radiograph imaging. (c) Microscale printing fidelity measured for two-layer lattice scaffolds printed by air extrusion with gelMA and 1-step gelMA-Au hydrogels. The printing fidelity of 1-step gelMA-Au hydrogels was comparable to that of gelMA alone. Error bars show one standard deviation of the mean (n = 5/group). (d) Macroscale printing fidelity measured for cylindrical tubes printed by DLP bioprinting with 1-step gelMA-Au hydrogels. Error bars show one standard deviation of the mean (n = 9/group). In (c) and (d), a ratio of one (dashed line) indicates no deviation from the CAD models. *p < 0.05, Tukey. **p < 0.005 vs. 1, exact t-test.