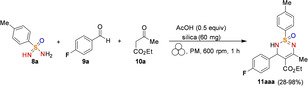

Table 1.

Optimization of the reaction conditions.[a] Adapted with permission from Ref. [58]. Copyright 2021, American Chemical Society.

|

| ||

|---|---|---|

|

Entry |

Deviation from standard conditions |

11 aaa yield[b] [%] |

|

1 |

none |

98 |

|

2 |

no silica, no acid |

n.r. |

|

3 |

no silica |

28 |

|

4 |

no acid |

28 |

|

5 |

NaCl instead of silica |

51 |

|

6 |

Na2SO4 instead of silica |

69 |

|

7 |

30 mg of silica |

89 |

|

8 |

100 mg of silica |

88 |

|

9 |

NH4Cl instead of AcOH |

93 |

|

10 |

Yb(OTf)3 (0.1 equiv.) instead of AcOH |

91 |

|

11 |

Cs2CO3 instead of AcOH |

92 |

|

12 |

39 balls instead of 20 |

95 |

|

13 |

0.20 mmol scale |

89[c] |

|

14 |

reflux in EtOH, AcOH (2.0 equiv.), 24 h |

n.r. |

[a] Reaction conditions: 8 a (0.10 mmol), 9 a (0.17 mmol), 10 aaa (0.15 mmol), planetary ball mill (PM) with ZrO2 Mg‐stabilized jars (size: 12 mL) and 20 ZrO2 Y‐stabilized balls (size: 5 mm). [b] Determined by quantitative 19F NMR spectroscopy [standard: 4,4′‐bis‐(trifluoromethyl)benzophenone]. [c] Yield after flash column chromatography. n.r.=no result.