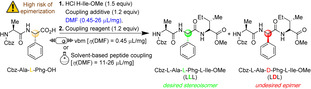

Table 7.

Comparative study between vibrating ball milling and solution synthesis of Z‐Ala‐Phg‐Ile‐OMe.[a,b] Adapted with permission from Ref. [115a]. Copyright 2021, American Chemical Society.

|

| ||||||

|---|---|---|---|---|---|---|

|

Entry |

Reagents |

T [°C] |

t [min] |

Yield [%] |

Purity[b] [%] |

LDL[b] [%] |

|

1 |

EDC⋅HCl/ Oxyma |

33 (33) |

10 (30) |

93 (88) |

>99 (32) |

<1 (9) |

|

2 |

EDC⋅HCl/HOBt⋅H2O |

34 (34) |

10 (30) |

90 (90) |

70 (48) |

25 (35) |

|

3 |

EDC⋅HCl/HOAt |

34 (34) |

10 (30) |

88 (90) |

95 (59) |

<1 (26) |

|

4 |

DIC/HOAt |

30 (31) |

10 (40) |

n.d. (n.d.)[c] |

67 (39) |

17 (33) |

|

5 |

DIC/Oxyma |

31 (31) |

10 (40) |

n.d. (n.d.)[c] |

46 (<10) |

<1 (n.d.)[c] |

|

6 |

HATU/Et3N |

34 (34) |

10 (60) |

85 (88) |

88 (58) |

1 (<1) |

|

7 |

HBTU/Et3N |

33 (33) |

10 (20) |

86 (82) |

71 (55) |

2 (9) |

|

8 |

EDC⋅HCl/ Oxyma[d] |

n.d.[c] |

30 |

96 |

>99 |

<1 |

[a] Milling reactions were performed in a 5 mL polytetrafluoroethylene (PTFE) jar with three stainless‐steel balls (5 mm diameter) at 25 Hz. The total mass of reactants was 50 mg. The values in parentheses correspond to solution reactions. [b] LDL=undesired epimer; determined by HPLC. [c] n.d.=not determined. [d] Reaction was performed on a total mass of 250 mg of reactants in a 15 mL PTFE jar with one stainless‐steel ball (10 mm diameter) at 25 Hz for 30 min using 1.7 equiv. of EDC⋅HCl. EtOAc was used as a liquid additive instead of DMF.