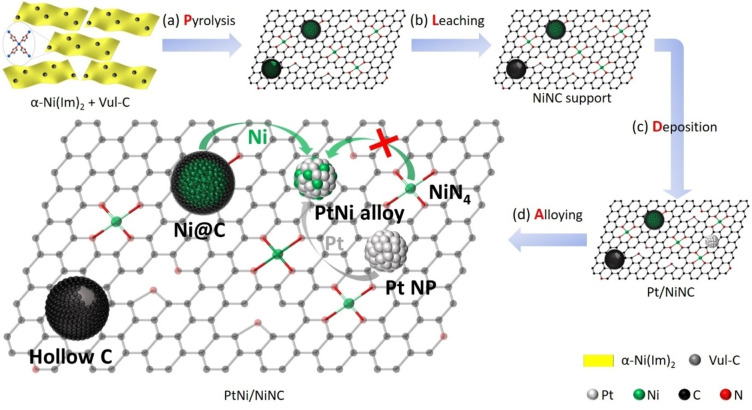

Figure 1.

Schematic illustration of the pyrolysis‐leaching‐deposition‐alloying (PLDA) strategy reported in this study. a) Pyrolysis of homogeneous mixture of nickel coordination polymer (NCP) precursor, α‐Ni(Im)2, and Vulcan carbon. During high‐temperature pyrolysis, Ni cations in α‐Ni(Im)2 either were reduced to metallic Ni NPs, or were transformed to single NiN x sites. b) Subsequent acid leaching to remove the partial unstable Ni NPs which were incompletely protected by the carbon shell, leaving a hollow carbon structure with an opening. Due to their acidic resistance, Ni NPs thoroughly covered by carbon shell, that was Ni@C structure, and single NiN x sites were left unchanged in this corrosive step. c) In situ deposition of 3 wt % Pt NPs onto NiNC support via simple polyol process. d) Formation of PtNi alloy NP was triggered by thermal annealing treatment. In the enlarged inset, the green and grey arrows represented the supplying routes of Ni and Pt during alloying process, respectively, whereas one green arrow with red cross indicated that the supplying route of Ni from single NiN x sites was not viable.