Abstract

The current importance of pumpkin (Cucurbita moschata) in national food security has progressively encouraged research on this fruit. This is how pumpkin seeds constitute a potential raw material to obtain dehydrated products for direct consumption. In this research, we compared the drying kinetics, effective diffusivity (Def) and sensory perception in a non-trained panel of dehydrated pumpkin seeds through refractance window drying (RW) and convective air drying (CA). RW drying was carried out in a laboratory-scale hydro-dryer and CA drying was carried out in a dryer with hot air circulation; both at 80 ± 2 °C. Sensory acceptability (appearance, aroma, taste and texture) was evaluated by an affective test on a hedonic scale from 1 to 5 with 60 panelists. The drying curves (MR vs t) were fitted to four kinetic models: Newton, Logarithmic, Page and Midilli et al. Def was determined by the second Fick’s Law solution. The best model for RW drying was logarithmic, and Def was 6.60 × 10−10 m2/s (R2 = 0.9927); while for CA, it was Midilli et al., with the Def found through this method being 9.60 × 10−10 m2/s (R2 = 0.9928). Dry seeds by RW obtained a general acceptance of 3.82, compared to 3.63 by CA. Results allow us to conclude that among the drying methods evaluated, there is not statistically significant differences, in terms of dehydration characteristics and sensory acceptability, constituting RW drying as an alternative method for obtaining dehydrate pumpkins seeds for direct consumption.

Keywords: Kinetic models, Refractance window, Pumpkin seeds, Sensory characteristics

Kinetic models; Refractance window; Pumpkin seeds; Sensory characteristics.

1. Introduction

The pumpkin is a plant-based product belonging to the Cucurbitaceae family (Ávila Pinilla, 2017). In Colombia in 2017, its production was 124,001 tons (Correa Álvarez et al., 2019), Cucurbita moschata being the predominant species whose stem is long, thin, and knotted. The fruit has a medium size with a softer shell and dark colored seeds, depending on its variety. The fruit can be presented in different shapes: spherical, ellipsoidal, oblate, pear-shaped, straight or curved bottle-shaped (León, 2000). In addition to its high macro and micronutrient content, the pumpkin is rich in phytoconstituents and antioxidants, with antifungal, anti-inflammatory and anticancer properties also being attributed to it (especially against lung and colon cancer) (Yadav et al., 2010). Physiologically, a pumpkin is made up of four main parts: the pulp, shell, seeds, and strands, all of which are edible, either directly or processed as a form of food enrichment; for example, soups, creams, and homemade sweets to bakery products with partial pumpkin flour substitution, as well as different pulp and seed snacks (Syam et al., 2020).

Pumpkin seeds have a high nutritional content: proteins (between 274.85 and 308.92 g/kg), carbohydrates (between 122.2 and 140.19 g/kg), lipids (between 439.88 and 524.34 g/kg) and ashes (between 44.22 and 55.02 g/kg), depending on the variety (Mi et al., 2012). Therefore, it could constitute a response to the national or global food security policy, not only because of its nutritional value, but also because of the diversity of consumption or forms of use; from flour to enriched bakery products (Jacinto et al., 2020), oils, ready-to-eat snacks, whether toasted or dried, to it being an ingredient in cereal bar production (Silva et al., 2014).

Refractance window drying (RW) is an innovative and efficient method for drying thin materials (Ortiz-Jerez et al., 2015). This type of drying is theoretically based on three ways of transferring heat: conduction, convection and radiation, using water as a heating medium. Water, at atmospheric pressure conditions and below the boiling point, transfers thermal energy to the product through a transparent plastic sheet to infrared radiation (e.g. Mylar™) (Ochoa-Martínez et al., 2012).

In addition, to guarantee energy efficiency, hot water is recycled and reused, reducing the cost by almost half when compared to lyophilization (Nindo and Tang, 2007; Puente-Díaz et al., 2020). In addition, it provides benefits in terms of the retention of quality characteristics from dehydrated foods, a greater energy efficiency, and inactivation of most pathogenic vegetative bacteria (Waghmare, 2021).

Mathematical models of drying processes are used to design new drying systems, to improve existing ones, or even to control the drying process (Doymaz, 2007). These are important when explaining the behavior of the process and extrapolating it to other operating conditions. Some models that have been successfully adjusted to the drying conditions of seeds of agricultural products, found in the literature, are the empirical or semi-theoretical models of Page, Lewis, or Henderson–Pabis for convective drying of grapes seeds (Roberts et al., 2008), Henderson-Pabis model for convective drying of Orange seed (Penteado-Rosa et al., 2015), Wang and Singh (empirical), Midilli et al., Page, Verma, Logarithmic and Approximation of Diffusion models for hot air drying of sunflower seeds (Smaniotto et al., 2017), Midilli et al., Logarithmic and Approximation of Diffusion, for convective drying of watermelon seeds (Dhurve et al., 2022), Logarithmic model for convective drying of hull-less pumpkin seeds (Sacilik, 2007), and Page model showed the best fitting result for fluidized bed drying of pumpkin seeds (Mujaffar and Ramsumair, 2019).

In order to dehydrate pumpkin seeds, several techniques have been used, such as fluidized bed drying with temperatures between 50 and 80 °C (Mujaffar and Ramsumair, 2019), solar tunnel drying (Sacilik, 2007), and traditional hot air drying (Can, 2007; Sacilik, 2007). However, there is little information on thin-layer modelling of pumpkin seeds using drying methods. There is, therefore, the need to study the thin-layer modeling of pumpkin seeds in order to understand the drying process. Currently, there are no literature reports for RW drying pumpkin seeds (C. moschata variety), nor information on the tastes and acceptability preferences by consumers for this product, which is important for knowing the market potential it may have, making it necessary to apply sensory analysis from methods known as consumer-oriented tests (COT) (Lawless and Heymann, 2010; Watts et al., 1989).

The objective of this research was to estimate the effective diffusivity and to determine the most appropriate thin layer kinetic model for refractance window (RW) drying of pumpkin seeds (C. moschata), as well as to evaluate the sensory perception of dehydrated samples in different attributes through a panel of untrained consumers.

2. Materials and methods

2.1. Plant material sampling and pretreatment

Pumpkin (C. moschata) was purchased at a local market in the city of Medellin (Colombia). It was then disinfected, peeled and cut around the equator, after which the seeds were separated from the strands and washed to remove residue. For this study, whole pumpkin seeds were used since no treatment was applied to remove the hull from the seed. They were kept at room conditions (RH = 68% and T = 25 °C) until the time of analysis. The samples' initial moisture was determined by the progressive heating infrared balance method using an analytical balance (Shimadzu, model ATX224, Japan).

2.2. Pumpkin seeds drying

Refractance window (RW) drying was carried out in a non-commercial laboratory scale hydro-dryer by using a 5 L thermostatic bath (Thermo Scientific, model TSGP05, USA) with water at a constant temperature of 80 ± 2 °C, covered with a transparent plastic sheet for infrared, in which approximately 25 g of the sample were placed, evenly spread, for each test (Figure 1). The plastic sheet is a sheet of polyethylene terephthalate (low-density polyethylene) transparent to infrared radiation known as Mylar® (Puente-Díaz et al., 2020).

Figure 1.

Schematic of the refractance window dryer (RW).

The bath temperature was set on the preliminary test basis, in which it was observed that a temperature above 80 °C created turbulence and air bubbles in the water bath, which interfered with the energy transfer through the sheet as mentioned in Clarke (2004). Additionally, according to literature revision, this temperature is equality efficient for the drying process while allows a better color and antioxidants content retention in food processing (Bernaert et al., 2019). For hot air drying (CA), a convective oven (Thermo scientific, model PR305225M, USA) was used at a constant temperature of 80 °C and an air speed of 0.8 m/s. All assays were carried out in triplicate. In each device, a single layer of pumpkin seeds distributed in the available drying area was dehydrated at the mentioned temperature (80 °C).

2.3. Sensory test

Consumer-oriented tests (COT) (Lawless and Heymann, 2010) such as preference (i.e., a comparison test) and acceptance (i.e., a hedonic scale), are easy to carry out. The latter is a test that measures the product’s subjective acceptance and preference by the consumer. It consists of delivering samples of the product to tasters and questioning them through a survey about their observations according to an established scale (Toscano-Palomar et al., 2020). In the hedonic scale, the taster expresses his or her acceptance of the product following a previously established scale, which gradually varies with the intensity of its attributes (Cordero-Bueso, 2017).

In order to know the acceptability of dried pumpkin seeds by refractance window as an alternative for direct consumption, the sensory characteristics of dehydrated products were evaluated by both drying methods: RW and CA, by the perception of an untrained panel and in a hedonic scale from 1 to 5, where 1 corresponds to “I dislike it very much”, 2 to “I dislike it”, 3 to “I slightly like it”, 4 to “I like it” and 5 corresponds to “I like it a lot”. An affective liking level test was applied to the attributes of appearance, aroma, taste and texture. 60 panelists of both sexes between 25 and 60 years old participated, belonging to different sectors of the city of Medellín. For all attributes, means and standard deviations were calculated for each treatment. An analysis of variance (ANOVA) was carried out using the Excel Statistical Add-in (Microsoft, version 2019). Sensory panelists were asked to sign a consent form to participate in a survey sponsored by the Universidad de Antioquia before receiving a set of paper instructions for performing the sensory test. The panelists were not informed about the differences between the samples used in the sensory tests, but they were assured of their safety and the confidentiality of data provided by each of them was guaranteed.

2.4. Kinetic drying model

Product moisture data (Xt) were taken at 80 °C every 5 min for 60 min, which were used to calculate the moisture dimensionless ratio (MR), defined as presented in Eq. (1):

| (1) |

where Xt, is the moisture content at any time t; X0, is the initial moisture content; and Xeq is the equilibrium moisture content, all expressed on a dry basis (kg water/kg dry solid). A Xeq of 0.005 kg water/kg dry solid was considered (Can, 2007; Pinho et al., 2011), which corresponded to the moisture reached by the samples in a long period of time, in which it is assumed that equilibrium with the surrounding humidity was reached.

Experimental curves (MR vs t) were fitted using Excel (Microsoft, version 2019), to four thin-layer kinetic models, which are frequently used to describe the drying of agricultural products. The Newton, Logarithmic, Page and Midilli et al. models, shown in Table 1, were selected. The goodness of fit for the empirical models was obtained with the following statistical parameters: R2 (distribution coefficient), 2 (chi square) and RMSE (root mean square error).

Table 1.

Kinetic models selected to describe pumpkin seeds drying.

| Model | Equation | Reference |

|---|---|---|

| Newton | MR= exp(-kt) | Lewis (1921) |

| Page | MR= exp(-ktn) | Page (1949) |

| Logarithmic | MR= a exp(-kt)+c | Sacilik (2007) |

| Midilli et al. | MR= a exp(-ktn)+bt | Midilli et al. (2002) |

2.5. Estimation of effective diffusivity

Effective diffusivity (Def) was obtained by the second Fick’s Law analytical solution (Eq. (2)) in rectangular coordinates, under the assumptions of moisture migration by diffusion in a single direction, with negligible shrinkage and external resistance. By solving Eq. (2), applying Crank’s solution (Crank, 1975), it gives Eq. (3) as a result:

| (2) |

| (3) |

where the Fourier number (Fo) is given by , where L is the product thickness (m).

3. Results and discussion

3.1. Sampling and pretreatment

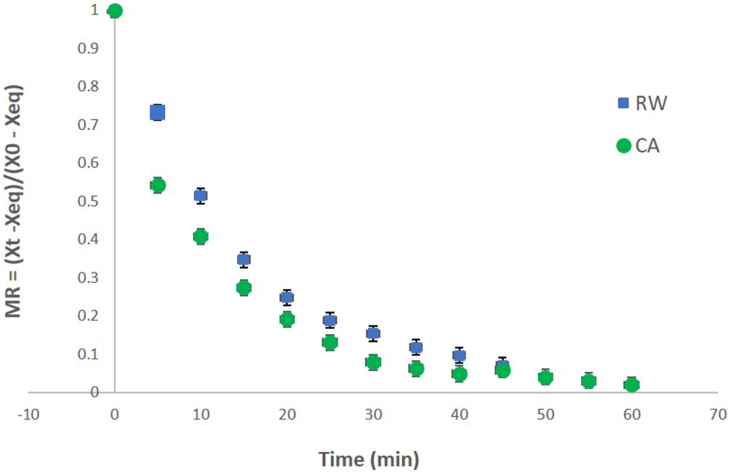

The samples had a thickness of 2.9 ± 0.3 mm and an initial moisture of 0.738 ± 0.013 kg water/kg dry solids (41.38 ± 3.12 % wb), these were dried to the final moisture content of 0.0112 kg water/kg dry solids for RW drying, and of 0.0129 kg water/kg dry solids for CA until no further changes in their mass were observed. Figure 2 shows that the CA method appears to be faster than RW drying. However, the vertical error bars may indicate that the differences are not statistically significant. The moisture ratio (MR) had values below 0.1 for both techniques. The samples reached a final moisture ratio of 0.07 for RW drying after 45 min and 0.02 for CA after 60 min. Similar results show that RW has a great capacity to dry foods in less time when is compared to CA at same temperature (Ochoa-Martínez et al., 2012; Jafari et al., 2015; Franco et al., 2019). Furthermore, RW drying has been suggested as a gentler method that can preserve the sensory attributes of the product (Jafari et al., 2015).

Figure 2.

Experimental drying curves for pumpkin seeds (C. moschata) by refractance window (RW) and convective air (CA) drying, at 80 °C.

In RW drying, the variation only decreases, which indicates that the governing mechanism is humidity diffusion, since the water evaporation on the surface is immediate thanks to the refractance window, making drying faster and more efficient (Nindo and Tang, 2007). On the other hand, for convective air drying, rates correspond to two zones: constant and decreasing, controlled by the evaporative and diffusional mechanisms, respectively. A slow diffusional stage can extend the drying time because most of the drying occurs in it, since moisture diffuses through a solid state at a slower rate (Montes et al., 2008; Olawoye et al., 2017).

3.2. Kinetic modeling

Table 2 presents the Newton, Logarithmic, Page, and Midilli et al. model parameters, as well as the goodness of fit parameters of each model. These results indicate that the four models satisfactorily describe the pumpkin seeds drying curves at the studied temperature, once their distribution coefficient values (R2) were higher than 95% and the relative mean errors (RMSE) less than 5%, for both drying methods. However, the model that best describes the data behavior in RW drying is the Logarithmic model, closely followed by the Midilli et al. model. Lately, this was also observed by Dhurve et al. (2022) in the convective drying of watermelon seeds. Similarly, the Midilli et al. model shows the best fit for CA, closely followed by the Page model. Likewise, Page model showed the best fitting result in a recent study about fluidized bed drying of pumpkin seeds (Mujaffar and Ramsumair, 2019).

Table 2.

Parameters and goodness of fit for the thin-layer mathematical models selected to describe the pumpkin seeds drying kinetics by refractance window and convective air drying.

| Model | Refractance window |

Convective air |

|||||||

|---|---|---|---|---|---|---|---|---|---|

| Parameter | Value | R2 | χ2 | RMSE | Value | R2 | χ2 | RMSE | |

| Newton | k | 0.0657 | 0.9981 | 0.0003 | 0.0185 | 0.0896 | 0.9945 | 0.0014 | 0.0377 |

| Logarithmic | k | 0.0703 | 0.9985 | 0.0003 | 0.0162 | 0.1021 | 0.9957 | 0.0007 | 0.0265 |

| a | 0.9847 | 0.9271 | |||||||

| c | 0.0223 | 0.0500 | |||||||

| Page | k | 0.0731 | 0.9982 | 0.0003 | 0.0177 | 0.1626 | 0.9981 | 0.0003 | 0.0175 |

| n | 0.9636 | 0.7772 | |||||||

| Midilli et al. | k | 0.0680 | 0.9984 | 0.0003 | 0.0166 | 0.1645 | 0.9982 | 0.0003 | 0.0174 |

| a | 1.0051 | 0.9974 | |||||||

| b | 0.0004 | -0.0001 | |||||||

| n | 1.0016 | 0.7690 | |||||||

These results indicate that the Midilli et al. model is a good model to represent the drying kinetics for both studied methods, as observed by Smaniotto et al. (2017), who studied eleven thin-layer models to adjust the sunflower seeds convective drying kinetics. In another research, Sacilik (2007) studied hull-less seed pumpkin (Cucurbita pepo L variety) drying at different temperatures with hot air, open solar drying and tunnel solar drying methods, and found that for all of them, the Logarithmic model is the one that best represents the thin-layer drying kinetics.

All of these studies about agricultural products seeds drying with thin-layer models analysis refer to good fit results with the models Logarithmic, Page and Midilli et al. mainly. The latter proved to be the most appropriate for RW drying of pumpkin seeds of C. moschata variety.

3.3. Estimation of effective diffusivity

It has been reported that the first three terms in Eq. (3), are enough to describe the drying process of small seed products (Can, 2007). However, considering a single direction of moisture flow and for sufficiently long times, the first term of the infinite series gives a good estimate (Dissa et al., 2011; Guiné and Barroca, 2012; Doymaz, 2018). The dimensionless Fo ratio was optimized using Excel SOLVER (2019) by truncating the infinite series in the first term. The linear section slopes of the dimensionless ratio Fo vs. time were obtained by linear regression analysis and were used to determine the effective water diffusivity coefficient (Def) (Table 3).

Table 3.

Pumpkin seeds thermal diffusivity according to the drying method.

| Drying | Effective diffusivity, Def (m2/s) | R2 |

|---|---|---|

| Refractance window (RW) | 6.60 × 10−10 | 0.9927 |

| Convective air (CA) | 9.60 × 10−10 | 0.9928 |

Table 3 shows the effective diffusivity average values of pumpkin seeds dried through the RW and CA techniques, at 80 °C. A comparison of means was made with the LSD method, and it was found that there is not statistically significant differences between both dryings Def values. These values are in the same order of magnitude as those reported in a study of melon seeds convective drying at temperatures between 50 and 70 °C (Almeida et al., 2020), and of pumpkin seeds drying in a fluidized bed at different air temperatures, including 80 °C (Mujaffar and Ramsumair, 2019). In another study, Sacilik (2007) observed that the hull-less seed pumpkin effective diffusivity was in the order of 10−11 at lower drying temperatures (40–60 °C). This was also observed by Smaniotto et al. (2017) during the sunflower seeds convective drying in a wide range of temperatures (35–95 °C). These variations occur because as the temperature increases, the vibration of water molecules increases and contributes to a faster diffusion (Coradi et al., 2016). It may also be due to the difference in reserves found in the seeds; because the higher the oil content inside, the lower the energy required for water removal (Smaniotto et al., 2017).

3.4. Sensory analysis

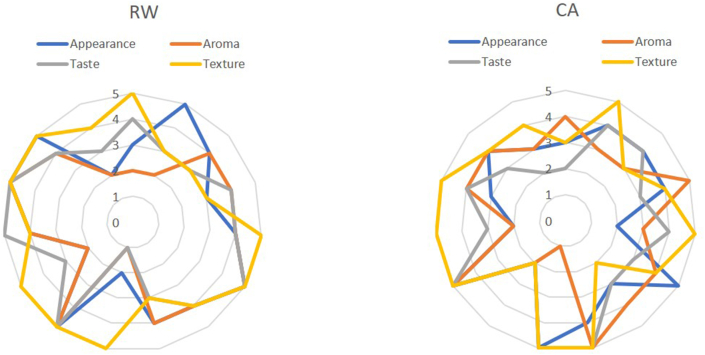

Figure 3 shows the test results for the four attributes (appearance, aroma, taste, texture) and general perception. The ANOVA indicated no statistically significant differences between the drying treatments, with a significance level of 95% (p < 0.05). Dry seeds by both drying methods, obtained a general acceptance between the range of 3–4, where 3 corresponds to “I like it slightly” and 4 to “I like it”. None of the values fell into the extreme category: “I dislike it a lot” or “I like it a lot”. For both RW and CA drying, the attribute with the highest rating was texture, while the attribute with the lowest rating was aroma, as seen in Figure 3. This can also be corroborated in the radial graphs shown in Figure 4.

Figure 3.

Sensory analysis of dried seeds by refractance window (RW) and convective air (CA) drying on a hedonic scale of 1–5.

Figure 4.

Sensory analysis in a radial graph for refractance window drying (a) and convective drying (b) on a hedonic scale of 1–5.

In a recent study with trained panelists, pumpkin seeds sensory profiles were evaluated, which were irradiated with high and low intensity electron beams. For aroma intensity, values between 4.2 and 4.5 were reported, and for taste between 6.0 and 6.3, on a scale from 1 to 10, when high irradiation intensity is used (Aisala et al., 2021), which are below those found in this study. In another study on sunflower seeds microwave drying and convective drying, according to the judges, the aroma intensity for convective drying was between 60 and 70%; this is similar to the aroma results found in the present study, whereas for the taste attribute these were lower (Goszkiewicz et al., 2020).

After texture, appearance and taste were the attributes best valued by participants. Since the appearance encompass all visually perceptible sensory impressions of foods, the advantages of drying foods using the RW technique in terms of this sensory aspect have been widely documented (Abonyi et al., 2002; Nayak et al., 2011; Baeghbali et al., 2016; Jafari et al., 2015; Puente et al., 2020). Given that it presents a slightly higher acceptability of the dry product, RW drying can be constituted as an alternative method for obtaining ready-to-eat dehydrated pumpkin seeds.

4. Conclusions

The drying kinetic characteristics of pumpkin seeds (C. moschata) are affected by the type of drying applied. The resulting effective diffusivities (Def) for both methods are in the same order of magnitude (10−10) and are in agreement with reports for similar agricultural products. The four evaluated kinetic models are useful for adjusting the pumpkin seeds drying curves, Midilli et al., model being the most suitable for this adjustment by refractance window (RW) drying. The dry product sensory acceptability is the same for both RW and CA, with texture being the attribute with the best rating, with aroma being the worst. RW drying is an alternative method for obtaining dehydrated pumpkin seeds for direct consumption (snack type). For future work, it is recommended to review the effect of RW drying' benefits on the nutritional and physical characteristics of seeds using instrumental methods.

Declarations

Author contribution statement

Mónica Jimena Ortiz-Jerez: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Angie Franco Sánchez: Performed the experiments.

Jose Edgar Zapata Montoya: Contributed reagents, materials, analysis tools or data; Analyzed and interpreted the data; Wrote the paper.

Funding statement

This work was supported by Universidad de Antioquia (2019-21550).

Data availability statement

Data included in article/supp. material/referenced in article.

Declaration of interest’s statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Acknowledgements

The authors would like to acknowledge to the Committee for the Development of Research, CODI – of University of Antioquia for financing this work, and the kind assistance of Instrumentation and maintenance of equipment team of University of Antioquia.

References

- Abonyi B.I., Feng H., Tang J., Edwards C.G., Chew B.P., Mattinson D.S. Quality retention of strawberry and carrot purees dried with refractance window system. J. Food Sci. 2002;6:1051–1056. [Google Scholar]

- Aisala H., Nygren H., Seppänen-Laakso T., Heiniö R.L., Kießling M., Aganovic K., Waser A., Kotilainen H., Ritala A. Comparison of low energy and high energy electron beam treatments on sensory and chemical properties of seeds. Food Res. Int. 2021;148 doi: 10.1016/j.foodres.2021.110575. [DOI] [PubMed] [Google Scholar]

- Almeida R.L., Santos N., Pereira T., Silva V., Ribeiro V., Silva L., Cordeiro Gomes F., Moreira F., Lima S., Eduardo R. Research, Society and Development; 2020. Cinética de secagem de sementes de melão descrita por um modelo de difusão. [Google Scholar]

- Ávila Pinilla N.S. 2017. El cultivo de auyama (Cucurbita moschata) híbrido bárbara un modelo demostrativo y productivo a corto plazo en la vereda La Unión del municipio de Puerto Lleras Meta.https://ciencia.lasalle.edu.co/ingenieria_agronomica/73 Retrieved from. [Google Scholar]

- Baeghbali V., Niakousari M., Farahnaky A. Refractance window drying of pomegranate juice: quality retention and energy efficiency. LWT Food Sci. Technol. 2016;66:34–40. [Google Scholar]

- Bernaert N., van Droogenbroeck B., van Pamel E., de Ruyck H. Innovative refractance window drying technology to keep nutrient value during processing. Trends Food Sci. Technol. 2019;84:22–24. [Google Scholar]

- Can A. An analytical method for determining the temperature dependent moisture diffusivities of pumpkin seeds during drying process. Appl. Therm. Eng. 2007;27(2–3):682–687. [Google Scholar]

- Clarke P.T. Proceedings of the 14th International Drying Symposium. IDS; 2004. Refractance window—Down under; pp. 813–820. [Google Scholar]

- Coradi P.C., Fernandes C.H.P., Helmich J.C. Adjustment of mathematical models and quality of soybean grains in the drying with high temperatures. Rev. Bras. Eng. Agrícola Ambient. 2016;20(4):385–392. [Google Scholar]

- Cordero-Bueso G.A. Tipos de pruebas de análisis sensorial. first ed. vol. 4. AMV Ediciones; Madrid (España): 2017. Análisis Sensorial de los Alimentos; pp. 155–182. [Google Scholar]

- Correa Álvarez E.M., Yacomelo Hernández M.J., León Pacheco R.I., Orozco Guerrero A.R., Silva Acosta G.E., Tamara Morelos R.E. Siembra; 2019. Modelo productivo de ahuyama para la región caribe colombiana; p. 1. [Google Scholar]

- Crank J. second ed. Oxford University Press; London: 1975. The Mathematics of Diffusion; pp. 69–88. [Google Scholar]

- Dissa A., Bathiebo D., Desmorieux H., Coulibaly O., Koulidiati J. Experimental characterisation and modelling of thin layer direct solar drying of Amelie and Brooks mangoes. Energy. 2011;36(5):2517–2527. [Google Scholar]

- Dhurve P., Kumar Arora V., Kumar Yadav D., Malakar S. Drying kinetics, mass transfer parameters, and specific energy consumption analysis of watermelon seeds dried using the convective dryer. Mater. Today Proc. 2022;59:926–932. [Google Scholar]

- Doymaz I. The kinetics of forced convective air-drying of pumpkin slices. J. Food Eng. 2007;79:243–248. [Google Scholar]

- Doymaz İ. Effect of pre-treatment and air temperature on drying kinetics and quality of Jerusalem artichoke. Sci. Stud. Res.: Chem. Chem. Eng., Biotechnol., Food Ind. 2018;19:395–409. [Google Scholar]

- Franco S., Jaques A., Pinto M., Fardella M., Valencia P., Núñez H., Ramírez C., Simpson R. Dehydration of salmon (Atlantic salmon), beef, and apple (Granny Smith) using Refractance windowTM: effect on diffusion behavior, texture, and color changes. Innovat. Food Sci. Emerg. Technol. 2019;52:8–16. [Google Scholar]

- Goszkiewicz A., Kołodziejczyk E., Ratajczyk F. Comparison of microwave and convection method of roasting sunflower seeds and its effect on sensory quality, texture and physicochemical characteristics. Food Struct. 2020;25 [Google Scholar]

- Guiné R.P., Barroca M.J. Effect of drying treatments on texture and color of vegetables (pumpkin and green pepper) Food Bioprod. Process. 2012;90(1):58–63. [Google Scholar]

- Jacinto G., Stieven A., Maciel M.J., Souza C.F.V. Effect of potato peel, pumpkin seed, and quinoa flours on sensory and chemical characteristics of gluten-free breads. Braz. J. Food Technol. 2020;23:1–12. [Google Scholar]

- Jafari S.M., Azizi D., Mirzaei H., Dehnad D. Comparing quality characteristics of oven-dried and refractance window-dried Kiwifruits. J. Food Process. Preserv. 2015;40(3):362–372. [Google Scholar]

- Lawless H.T., Heymann H. Food Science Texts Series. second ed. vol. 23. Springer; 2010. Sensory evaluation of food: principles and practices; p. 596. [Google Scholar]

- León J., editor. Botánica de los cultivos tropicales. third ed. Agroamérica; 2000. [Google Scholar]

- Lewis W.K. The rate of drying of solid materials. J. Ind. Eng. Chem. 1921;13:427–432. [Google Scholar]

- Mujaffar S., Ramsumair S. Fluidized bed drying of pumpkin (Cucurbita sp.) seeds. Foods. 2019;8(5):147. doi: 10.3390/foods8050147. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mi Y.K., Eun J.K., Young-Nam K., Changsun C., Bo-Hieu L. Comparison of the chemical compositions and nutritive values of various pumpkin (Cucurbitaceae) species and parts. Nutr. Res. Pract. 2012;6(1):21–27. doi: 10.4162/nrp.2012.6.1.21. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Midilli A., Kucuk H., Yapar Z. A new model for single layer drying. Dry. Technol. 2002;20:1503–1513. [Google Scholar]

- Montes E.J., Torres Gallo R., Andrade Pizarro R.D., Pérez Sierra O.A., Marimon Escobar J.L., Meza Herazo I.I. Modelling the kinetics of thin-layer yam (dioscorea rotundata) drying. Ing. Invest. 2008;28(2):45–52. [Google Scholar]

- Nayak B., Berrios J.D.J., Powers J.R., Tang J., Ji Y. Coloured potatoes (Solanum tuberosum L.) dried for antioxidant-rich value-added foods. J. Food Process. Preserv. 2011;35:571–580. [Google Scholar]

- Nindo C.I., Tang J. Refractance window dehydration technology: a Novel Contact drying method. Dry. Technol. 2007;25(1):37–48. [Google Scholar]

- Ochoa-Martínez C.I., Quintero P.T., Ayala A.A., Ortiz M.J. Drying characteristics of mango slices using the Refractance Window technique. J. Food Eng. 2012;109:69–75. [Google Scholar]

- Olawoye B.T., Kadiri O., Babalola T.R. Modelling of thin-layer drying characteristic of unripe Cardaba banana (Musa ABB) slices. Cogent Food Agric. 2017;3(1) [Google Scholar]

- Ortiz-Jerez M.J., Gulati T., Datta A.K., Ochoa-Martínez C.I. Quantitative understanding of refractance WindowTM drying. Food Bioprod. Process. 2015;95:237–253. [Google Scholar]

- Page G.E. Purdue University; West Lafayette: 1949. Factors Influencing the Maximum Rates of Air Drying Shelled Corn in Thin Layers. [Google Scholar]

- Penteado-Rosa D., Cantú-Lozano D., Luna-Solano G., Polachini T.C., Telis-Romero J. Mathematical modeling of Orange seed drying kinetics. Cienc. E Agrotecnol. 2015;39(3):291–300. [Google Scholar]

- Pinho S., Guiné R.P., Barroca M.J. Study of the convective drying of pumpkin (Cucurbita maxima) Food Bioprod. Process. 2011;89(4):422–428. [Google Scholar]

- Puente-Díaz L., Spolmann O., Nocetti D., Zura-Bravo L., Lemus-Mondaca R. Effects of infrared-assisted refractance WindowTM drying on the drying kinetics, microstructure, and color of Physalis fruit Purée. Foods. 2020;9(3):343. doi: 10.3390/foods9030343. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Puente L., Vega-Galvez A., Ah-Hen K.S., Rodríguez A., Pasten A., Poblete J., et al. Lebensmittel-Wissenschaft und -Technologie- Food Science and Technology; 2020. Refractance Window Drying of Goldenberry (Physalis Peruviana L.) Pulp: A Comparison of Quality Characteristics with Respect to Other Drying Techniques; p. 131. [Google Scholar]

- Roberts J.S., Kidd D.R., Padilla-Zakour O. Drying kinetics of grape seeds. J. Food Eng. 2008;89(4):460–465. [Google Scholar]

- Sacilik K. Effect of drying methods on thin-layer drying characteristics of hull-less seed pumpkin (Cucurbita pepo L.) J. Food Eng. 2007;79(1):23–30. [Google Scholar]

- Silva J.S., Marques T.R., Simão A.A., Corrêa A.D., Pinheiro A.C.M., Silva R.L. Development and chemical and sensory characterization of pumpkin seed flour-based cereal bars. Food Sci. Technol. (Campinas) 2014;34(2):346–352. [Google Scholar]

- Smaniotto T.A.D.S., Resende O., Sousa K.A.D., Oliveira D.E.C.D., Campos R.C. Drying kinetics of sunflower grains. Rev. Bras. Eng. Agrícola Ambient. 2017;21(3):203–208. [Google Scholar]

- Syam A., Zainal, Kurniati Y., Hardiyanti, Ulfasari I., Ishak A., Akhmar A.M. Preference test of biscuit products from pumpkin seeds (Cucurbita sp.) Enfermería Clínica. 2020;30:375–378. [Google Scholar]

- Toscano-Palomar L., García-Gómez G., Gómez-Puentes F.J., Beltrán-González G., Valenzuela-Espinoza I.G., Armenta-Gálvez J.M. Análisis de las propiedades físico-químicas y sensoriales de barra alimenticia a base de semillas y nueces sin componentes de origen animal. Rev. Española Nutr. Humana Dietética. 2020;24(2):143–153. [Google Scholar]

- Waghmare R. Refractance window drying: a cohort review on quality characteristics. Trends Food Sci. Technol. 2021;110:652–662. [Google Scholar]

- Watts B.M., Ylimaki G.L., Jeffery L.E., Elias L.G. International Development Research Centre; Ottawa (Canada): 1989. Basic Sensory Methods for Food Evaluation. [Google Scholar]

- Yadav M., Jain S., Tomar R., Prasad G., Yadav H. Medicinal and biological potential of pumpkin: an updated review. Nutr. Res. Rev. 2010;23(2):184–190. doi: 10.1017/S0954422410000107. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supp. material/referenced in article.