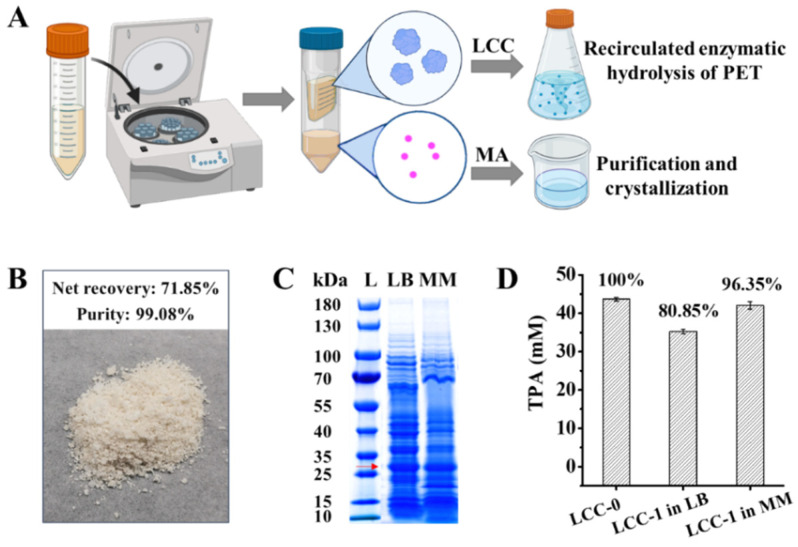

Figure 5.

Separation of LCC from MA and used for the new round of hydrolysis of PET. (A), The process for separating the end product MA and the reproduced LCC; (B), recovery rate and purity of the obtained MA powder; (C), SDS-PAGE analysis of the crude enzyme produced when the bioconversion of PET hydrolysates occurred concurrently in LB or mineral medium (MM). There is a clear thickened band at the size of LCC (approximately 27.8 kDa); (D), activity comparison of LCC crude enzyme form different resources. LCC-0, crude enzyme produced from LB without bioconversion of PET hydrolysates; LCC-1 in LB, crude enzyme produced from LB when the bioconversion occurred concurrently; LCC-1 in MM, crude enzyme produced from MM when the bioconversion occurred concurrently. Error bars indicate the standard deviation based on duplicate parallels.