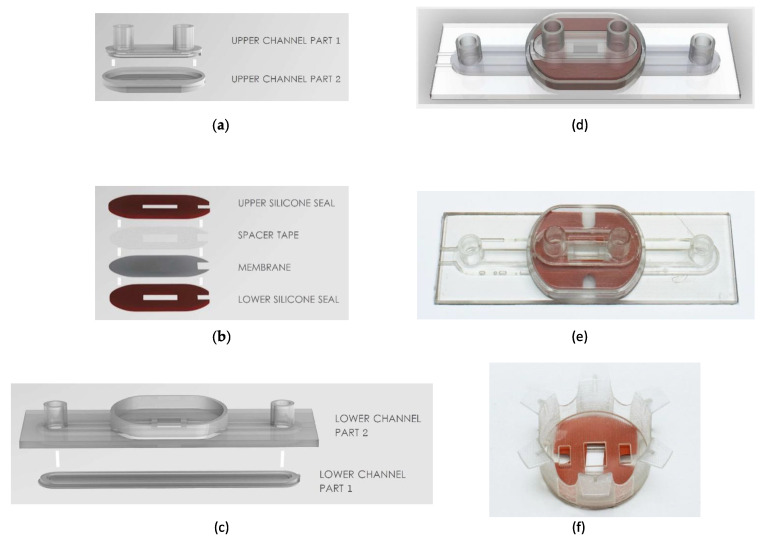

Figure 1.

The fabrication process of the TripleB fluidic chip, beginning with the sub-assembly in (a) which shows the formation of the upper fluid channel (for endothial cells) comprising two rigid bodies (upper channel part 1 and upper channel 2), which are 3D printed using biocompatible MED610 resin, and are then sealed along the edges using uncured MED610 resin, which is then separately cured with a UV lamp; (b) then, the assembly of the removeable membrane is performed, which consists of a porous membrane with 3.0 µm pore size (Oxyphen) and spacer tape to support the delicate porous membrane structure, which are then sandwiched between an upper and lower layer of silicone rubber (Shore hardness 30 A) to ensure a tight seal between the rigid bodies of the upper and lower channels—the shapes of these components were fabricated using mechanical die-cutting and punching and exposed a surface area of 4 × 8 mm or 0.32 cm2 on either side of the porous membrane for the growth of the endothelial and astrocyte cells; (c) the formation of the lower fluid channel (for astrocyte cells) comprising two rigid bodies (lower channel part 1 and part 2). These parts are fabricated and sealed using the same method as the upper channel. These three sub-assemblies are combined together, as shown with (d) a render and (e) a photograph of the fabricated TripleB fluidic chip. A photograph of the novel transwell insert is shown in (f) which comprises the two rigid bodies (the flanged carrier and the cover with bayonet-type connection) and the removable membrane assembly.