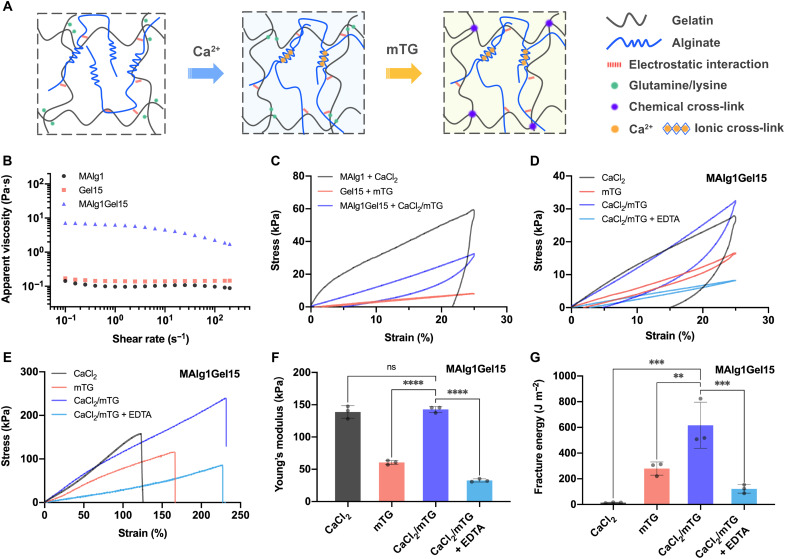

Fig. 1. Design and mechanical properties of tough DN hydrogel (bio)inks.

(A) Schematics of DN hydrogel containing physically cross-linked alginate by calcium as the first network and chemically cross-linked gelatin by mTG as the second network. (B) Apparent viscosities as a function of shear rate for (bio)ink (MAlg1Gel15) and its individual components (MAlg1 and Gel15) at 37°C. (C) Loading-unloading tensile stress-strain curves of MAlg1, Gel15, and MAlg1Gel15 hydrogels cross-linked by CaCl2, mTG, and CaCl2/mTG, respectively. The maximum strain was 25%. (D) Loading-unloading tensile stress-strain curves of the MAlg1Gel15 hydrogels with four different cross-linking and posttreatment methods: CaCl2, mTG, CaCl2/mTG, and CaCl2/mTG/EDTA. The maximum strain was 25%. Tensile stress-strain curves (E), Young’s moduli (F), and fracture energies (G) of MAlg1Gel15 hydrogels with four different cross-linking and posttreatment methods: CaCl2, mTG, CaCl2/mTG, and CaCl2/mTG/EDTA. ns, no significant difference. **P < 0.01, ***P < 0.001, and ****P < 0.0001.