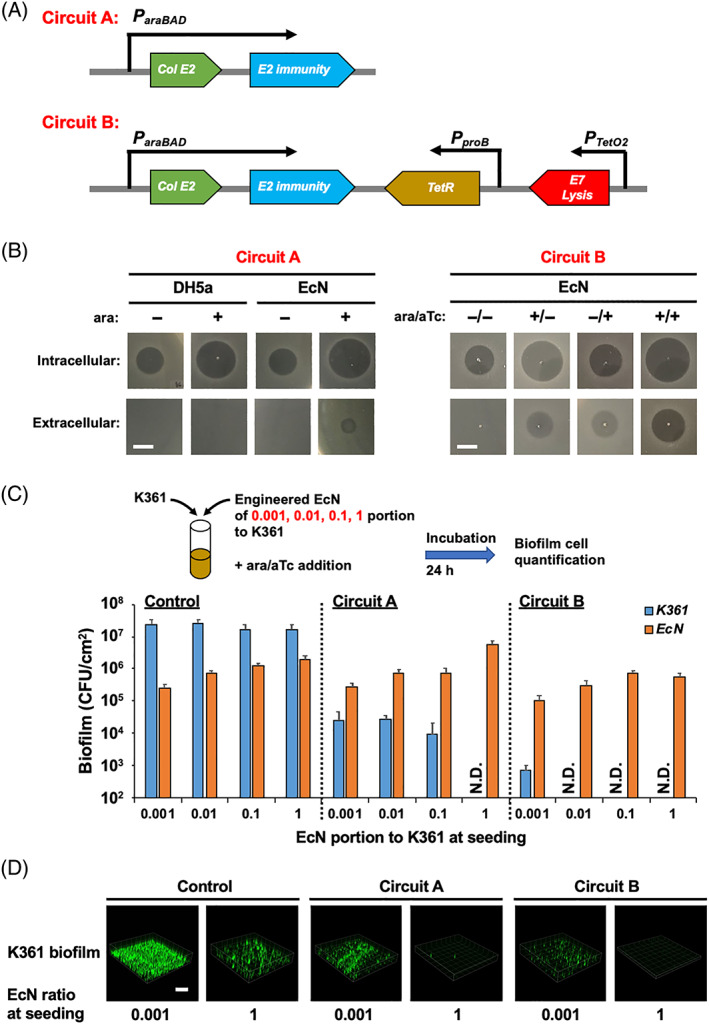

FIGURE 3.

Design and validation of colicin‐producing genetic circuits. (A) Genetic circuit for colicin E2 and its immunity gene expression controlled by L‐arabinose (circuit A). Improved genetic circuit with the addition of E7 lysis gene expression induced by anhydrotetracycline; tetR gene was added to circuit A (or circuit B). (B) For circuit A, colicin E2 was produced with 0.1% L‐arabinose (ara) induction and secretion. For circuit B, colicin E2 was produced with 0.1% ara, and lysis protein was produced with 500 nM of anhydrotetracycline (aTc). K361 inhibition zones were formed at 37°C for 24 h with cell‐free supernatants containing colicin E2, with sonication (intracellular) and without sonication (extracellular). The scale bar indicates 0.5 cm. (C) Dual‐species biofilm formation of engineered EcN with circuit A (pBAD‐E2), circuit B (pBAD‐E2+lys), or control (pBAD‐gfp) with K361 indicator cells in various proportions (0.001, 0.01, 0.1, and 1 ratios of EcN to the K361 population) at seeding. Biofilms were formed at 37°C for 8 h and incubated for an additional 16 h with 0.1% ara or 500 nM of aTc. Viable biofilm cells are quantified in colony‐forming units per area (CFU/cm2). Error bars indicate the standard deviation from two independent cultures with three replicates. (D) K361 biofilm images under the same conditions as in (C). The scale bar indicates 200 μm