Abstract

Diamond is a form of carbon that has been attracting attention for hundreds of years, owing to its physical and chemical properties of hardness, thermal conductivity, chemical inertness, and transparency. Labor and the long-term impact of a diverse workforce, is one of the most important factors in diamond mining and production and must be considered when assessing economic benefits. In the present study, we examined the labor input required to obtain one carat of diamond, via three methods: open-cast mining, high-pressure high-temperature synthesis and 2.45-GHz microwave plasma chemical vapor deposition. We discovered that to produce a carat of (near-) colorless diamond, the labor inputs are approximately 1.83 h and 3.43 h of work using the HPHT and 2.45-GHz MP CVD methods, respectively. We noted a lower labor input of work per carat for the mining of diamonds of assorted sizes and colors from the two main DeBeers diamond fields in Botswana (Orapa and Jwaneng). This paper is based on our observations and public reports, and we think that our findings will be helpful in understanding the labor input per carat for the analyzed methods, understanding the main technological challenges facing the diamond industry that could potentially affect future labor productivity.

Keywords: Labor productivity, Labor input, High-pressure high-temperature synthesis, Chemical vapor deposition, Diamond mining

Labor productivity; Labor input; High-pressure high-temperature synthesis; Chemical vapor deposition; Diamond mining.

1. Introduction

Diamond synthesis is a major challenge not only for the jewelry industry but also for electronics, quantum communication, thermal management and etc. Some companies, such as the DeBeers Group (Element Six, 2016), have already diversified their product range to offer customers both mined and lab-grown diamonds, at different prices (“Element Six | Synthetic Diamond and Tungsten Carbide Experts”). However, the majority of diamond mining and trading companies continue to focus only on mined diamonds, the quality of which are enough for the jewelry. Depending on the mine, the size of rough diamond can vary from a few hundredths of a carat to stones weighing more than 1000 carats. The largest and arguably the most famous gem-quality diamond ever to be found is the beautiful Cullinan diamond, the rough diamond weighed 3106 carats when it was mined in South Africa by Sir Thomas Cullinan, in 1905. Although Cullinan is known as one of the largest gemstones ever found, the Black Diamond was found in Brazil in 1893 and weighs a total of 3167 carats (“Top 8 largest diamonds in the world | CT Diamond Museum,” 2017). The average size of rough diamond mined can weight from 0.01 ct to more than 0.7 ct. (“Indian Minerals Yearbook 2019 (Vol - III: MINERAL REVIEWS)”).

Despite ongoing diamond mining and debates about the benefits and business opportunities of diamond synthesis, diamond growers have contributed significantly to the new range of meta-materials (Tikhomirova et al., 2020), quantum technology (Babinec et al., 2010), thermal management (Palko et al., 2017) much like medieval alchemists, who enhanced practical technology while looking for the “philosopher’s stone.” Businesses examining and comparing new manufacturing methods must estimate the main input costs of each method, in order to choose the most suitable one.

Diamond synthesis can be achieved through several different technologies. Briefly, these are the following:

-

1.

High-pressure high-temperature (HPHT) diamond synthesis (Yunin et al., 2018), was first used commercially after publication in the 1950s by General Electric and has undergone decades of intensive development. It is the oldest technique and is considered efficient. The majority of lab-grown diamonds, especially small diamonds and those used in technical applications, are grown using the HPHT method. According to the available data, the largest man-made colorless rough diamond grown by the HPHT method by St. Petersburg-headquartered New Diamond Technology LLC, in less than 300 h weighed 32.26 carats (“World’s largest colorless grown diamond | New Diamond Technology”). Also, New Diamond Technology managed to grow by HPHT method for 400 h a nitrogen-containing diamond weighing 129.47 carats and sized 29.5 × 29.5 × 21 mm (“New World Record in diamond Growing”). The blue crystal weighs 150.42 carats and sized 28.55 × 28.25 × 22.53 mm and the gray crystal weighs 141.58 carats and sized 28.90 × 28.50 × 20.75 mm. Both crystals were produced by biotech company Meylor Global using the HPHT process (“Lab-Grown Diamonds Setting New Size Records”)

-

2.

Chemical vapor deposition (CVD) is a new and promising diamond synthesis technology. There are several different types of sub-methods of CVD (Schwander and Partes, 2011; Spitsyn et al., 1981) such as hot filament (HF), direct current (DC), and microwave plasma (MP) CVD (Schwander and Partes, 2011). HF and DC CVD have many advantages, such as their productivity, but the resulting diamonds have limited applications, such as abrasive and cutting purposes (i.e. surgery scalpels), gemstones, and are not suitable for high-tech electronic and optic applications (Mankelevich et al., 1998; Polushkin et al., 1994). The MP CVD method, by contrast, creates superior-quality products that are acceptable for all the purposes mentioned above, i.e., from jewelry to quantum memory (Wu et al., 2016). MP CVD allows for excellent control of impurity levels, which is essential for growing high-quality crystals for optical, electronic, or gemstone usage. The largest CVD diamond is a 16.41-carat princess-cut stone grown by Shanghai Zhengshi Technology Co. Ltd (“GIA Examines Largest Known Diamond Grown Using CVD”)

-

3.

Other synthesis methods include detonation (Dolmatov, 2008; DeCarli and Jamieson, 1961) and cavitation (Galimov, 1973; Frank et al., 1973), in which diamonds are formed through explosive and ultrasonic impact, respectively. These methods, however, are still vastly inferior to HPHT and CVD, in terms of the size and quality of the resulting diamonds. Nonetheless, detonation and cavitation remain very promising in terms of cost-effectiveness. It seems only a question of time before these methods become developed enough to enter the mainstream.

In our previous article, we already examined the expenditure of resources, such as water and energy, in mining and producing diamonds by various methods (Zhdanov et al., 2021). We have now decided to look at labor input as one of the major contributors to the operational expenses of synthetic diamond production and diamond mining. We hope that our practical data on a general breakdown of the labor required for various diamond synthesis methods, as well as for open-pit mining, will be useful to those interested in diamond synthesis, both for commercial and academic purposes.

2. Approach and assumptions used for analysis

2.1. Limitations and conditions

The present study focuses on diamond mining and two synthetic diamond production methods such as HPHT and 2.45 GHz MP CVD.

There are three stages to all methods of diamond production: upstream, middle stream, and downstream. These terms have been borrowed from the oil industry (Devold) and are used by the DeBeers Group in their reports (“The Diamond Insight Report 2021”), with mining forming part of their upstream process. Different lab manufacturers participate in different processes: some only grow diamonds, while others grow, cut, and polish them. There are also fully-integrated manufacturers who participate in all the processes, from synthesis to working with wholesale buyers. In this study, we focus on the production of both mined and synthesized diamonds, i.e., on the upstream stage.

Some data in this study were approximated, to present the potential of a particular method of synthesis. For instance, while promising techniques have been developed in the field of CVD synthesis, they are currently employed by a variety of entities. If they were combined into a single streamlined process and used together, the paradigm would shift. That is why we will map the main trends which have the potential to dramatically affect labor input.

The Organization for Economic Co-operation and Development (OECD) defines national labor productivity (OECD, 2021) as the gross domestic product (GDP) per hour worked; we also use the number of hours worked in our calculations, as a measure of labor. Moreover, we use the labor required to produce one carat of rough diamond (hw/ct) to compare labor input across different parts of the diamond industry. Therefore, 1 hw/ct indicates that 1 h of work is required to obtain one carat of a rough diamond.

2.2. Data sourses

To examine labor input in the diamond mining process, the relevant data were sourced from public reports of Debswana (“Welcome to Debswana”; “Botswana”), which is the main diamond contributor to DeBeers (68% in 2018, (“Production Reports”)). DeBeers is one of the most-studied companies by business schools, as an example of a company with an effective future-oriented approach, including the area of social responsibility.

To determine the labor input (hw/ct) required for each diamond production method, we first acquired a broad overview of each process, and the kinds of labor operations and staff required at each stage of the process. We then calculated the labor input (in hours worked) per carat of rough diamond produced, for each production method. For HPHT and CVD, we obtained data by visiting various diamond synthesizing plants in Russia.

2.3. Expected assumptions

Based on our experience and observations, we put forward several hypotheses about labor productivity in the diamond industry that need to be confirmed or refuted:

-

1.

The HPHT method has recently become more effective in terms of labor productivity than other synthesis methods.

-

2.

The CVD and HPHT methods have the potential to bridge the diamond labor productivity gap.

-

3.

There are unique diamond fields where labor input per carat is significantly lower for both HPHT and CVD methods.

3. Results

Although diamond mining does not leave as much toxic chemical waste as the extraction of precious metals, it involves the creation of deep pits, which means disturbing the soil and possibly cutting down the forest at the site of the deposit. All these factors can lead to changes in the ecosystem and should be considered. So based on our experience and ecological trends, we decided to focus first on synthetic diamond production analysis with the two most popular methods: HPHT and MPCVD, and then consider diamond mining.

3.1. HPHT

The HPHT method reflects the natural process of diamond formation under high pressure and temperature (Bundy et al., 1955). Central to the HPHT process is a chamber that contains a mix of iron, cobalt, nickel, and graphite (which acts as the source of carbon).

Tiny diamond seeds are initially placed into the mix in the chamber and later become the centers of nucleation. However, if the aim is to produce only powder-like diamonds, no seeds are needed. A powerful hydraulic system shown in Figure 1 pressurizes the chamber, up to 6 GPa, and an internal heating controller supports temperatures of approximately 1500 °C (Khmelnitskiy, 2015).

Figure 1.

HPHT synthetic diamond hydraulic press.

Our observations revealed that the common modern HPHT presses are highly productive, producing approximately 1200 carats per year, as confirmed by the published data of the Russia-based company New Diamond Technology (NDT), which is one of the global technological leaders in the HPHT area (Deljanin et al., 2015). The ability to grow approximately 1200 carats per year, using commercially-available HPHT presses, is very important in our further calculations of labor input which depends on press productivity (DHaenens-Johansson et al., 2015). However, each manufacturer for a set HPHT process has its own recipe with its own temperature and pressure modes and correspondingly its own performance. Moreover, as technology develops, the data changes rapidly and in most cases this information is kept confidential. The leading manufacturers of cubic presses on an industrial scale are currently Chinese companies. Using their upgraded HPHT press, it is possible to synthesize on average up to 200 carats of diamonds per month, respectively about 2400 carats per year, depending on the technology, size of synthesized crystals and quantity of initial seed diamonds. (“Technology vs monopoly. Market overview of lab-grown gem-quality diamonds. Part 1. Upstream∗”)

HPHT presses are typically assembled into an array, to optimize water-cooling, energy supply, and operational services. The total number of presses in one array varies widely between different manufactures. China-based market leaders use arrays of hundreds of presses, while quality-focused EU, Russia, and Ukraine “art-growers” use arrays of only a few presses. After visiting many HPHT facilities we arrived at a simple estimation: on average, one person is required to operate each press.

Our calculation considers a typical HPHT array consisting of 30 modern HPHT presses comprising two models, with working cylinder diameters of 750 mm and 850 mm, respectively. The yearly productivity of each press according to data of NDT company is approximately 1200 carats of jewelry-size colorless and near-colorless (D-J according to Gemology Institute of America classification (“Diamond Quality Factors”)) diamonds. The total productivity of a 30-press HPHT array is therefore nearly 700 carats per week if the machines are working on a 24/7 regime. In case of Chinise companies, yearly productivity of each press is approximately 2400 carats. The total productivity of a 30-press HPHT array is therefore nearly 1380 carats per week if the machines are working on a 24/7 regime.

An example of people distribution in an array of 30 HPHT presses is presented in Table 1.

Table 1.

The workforce required to operate a 30-press HPHT array running on a 24/7 regime.

| Functionality | Total |

|---|---|

| Operators | 5 |

| Engineer-technologists | 5 |

| Chemists | 5 |

| Tooling-specialists | 7 |

| Hydraulic engineer | 1 |

| Electric engineer | 1 |

| Water and infrastructure engineer | 1 |

| System administrators | 2 |

| Supply and logistic | 2 |

| Cooling-system engineer | 1 |

| Managers | 2 |

| Total | 32 |

This table shows approximately 32 people are needed to support a 30-press HPHT array, operating on a 24/7 regime, and growing approximately 700 carats of gem-quality average-sized (near-) colorless diamonds per week.

The core personnel, who are responsible for the entire process, are the operators, engineer-technologists, and chemists. They reload and launch the presses approximately once every 12 days, and control all the parameters during the process, including pressure and temperature; they also mix metal powders (iron with cobalt, nickel, and other additives) with graphite and the initial diamond seed(s). They extract the newly created diamonds at the end of the synthesis operation and use strong acids to remove them from the metal medium. This group of staff accounts for the main core competence (Prahalad and Hamel, 2000) of the operation and an inexperienced operator/technologist/chemist would reduce the performance dramatically. Other staff play supporting roles in the HPHT team, each focusing on a particular function that maintains the process. These roles include highly skilled engineers, suppliers, and administrators. Each role is important to ensure that the HPHT process runs on the 24/7 regime. Typically, these professionals work 40 h per week.

Taking all of this into consideration, we arrived at the following simple calculations for Russian based (Eq. (1)) and Chinise based companies (Eq. (2)), respectively:

| 32 × 40 h worked per week/700 carats = 1.83 h worked per carat (hw/ct) | (1) |

| 32 × 40 h worked per week/1380 carats = 0.93 h worked per carat (hw/ct) | (2) |

This estimation of labor input is applicable to (near-) colorless medium-sized rough diamonds and will be significantly different for the production of either “dark” nitrogen-rich or small diamonds (Hainschwang et al., 2020). The presence of nitrogen in the HPHT chamber can significantly enhance the speed of growth, as nitrogen readily replaces carbon (С) and produce solid solution. Growing many smaller diamonds in a chamber requires less time than growing larger ones. One press can produce small-sized diamonds in days, or medium-sized ones in weeks. The total mass of diamonds will depend on the graphite mass at the beginning of each cycle. Therefore, more nitrogen and a smaller target size result in greater productivity for an HPHT press, but the resulting diamonds are generally small, yellowish to dark brown in color, and are, therefore, less economically attractive to producers. We, therefore, focus on nitrogen-free (near-) colorless medium-sized diamonds, which are well-priced and are generally in more demand.

3.2. MP CVD

The MP CVD method of growing diamonds is very different from the HPHT method and does not replicate a natural process. It uses methane-hydrogen plasma, instead of an iron-based graphite melt, and takes place in a low vacuum inside a CVD chamber. The CVD method allows for the creation of complicated crystal structures for jewelry, optics and electronics and precise control of all relevant synthetic parameters.

There are plenty of academic studies about the CVD process (Bühlmann et al., 1999; Ivanov et al., 2015; Khomich et al., 2001), including a detailed DeBeers-affiliated handbook (Element Six, 2016). Different CVD processes are existing between them: hot filament (i.e. wolfram electrode), direct current (Lyu et al., 2019) (i.e. discharge between two molybdenum disks), or microwave radiation (Khmelnitskiy, 2015). Such processes are referred to as HF, DC, and MP CVD, respectively. Depending on the different CVD processes, the following condition should be achievable:

-

•

Methane (CH4; a large blue ball with four small red balls, Figure 2) and hydrogen (H2; red coupled balls, Figure 2) disintegrate into methyl radicals and atomic hydrogen, which are both very unstable, and the vast majority of them promptly integrate back into CH4 and H2. Some methyl radicals are absorbed to the diamond lattice (blue structure in Figure 2) and are later dehydrogenated (schematically: CH4 + 2H2 = CH3 + H + 4H = C + 4H2).

-

•

To support the dissociation of methane and hydrogen, a high temperature or plasma enhances are needed.

-

•

A low pressure combined with a temperature gradient (diamond surface should be slightly colder) is required to control the synthesis process.

Figure 2.

Scheme of MP CVD process chemistry and 2.45-GHz MP CVD reactor. (1) magnetron; (2) chamber (where diamonds grow); (3) control panel, (4) pumps, (5) electric, gas, and refringent supply cables.

We have already mentioned the disadvantages of HF and DC CVD, related to the risk of impurity. Such impurities are undesirable for electronic and optic projects, which is why we limit our analysis to MP CVD, where plasma is usually created by a magnetron (gyrotron-supported CVD reactors are also used, but are not very common (Glyavin et al., 2020; Vikharev et al., 2006)). CVD reactor magnetrons operate on specific frequencies of 915 MHz (Ando et al., 2002) or 2.45 GHz (Horino et al., 2006). As the authors of this study have no experience using 915 MHz magnetrons, we have limited our discussion to the 2.45 GHz MP CVD method. In the CVD process, the speed of diamond deposition, and therefore the productivity, depends to a large extent on the plasma density (Silva et al., 2009b), though many other parameters must also be taken into consideration. If all other parameters are equal (including magnetron power and the inner pressure of the CVD chamber), the main difference between the two magnetron frequencies is the plasma distribution. A 915-MHz magnetron results in a larger plasma “spot” than a 2.45-GHz magnetron.

The labor input for the CVD process is also correlated with the mix of gasses that are used. Methane CH4 is a widely used source of carbon in the CVD process, although some researchers have successfully used other carbon-based gasses (Kitaura et al., 2015). Such process has one major disadvantage in that it is explosive, which demands more attention when working to avoid any risk to staff. This fact is important for labor input, as someone experienced should be responsible for methane supply. On average, the plasma in the CVD reaction is based on hydrogen (H2), with only a small fraction of methane, just enough to support deposition (Figure 2). Although hydrogen is even more explosive than methane, modern hydrogen stations can work automatically on a 24/7 regime and do not require a lot of staff attention, and one hydrogen station can easily support an array of CVD reactors.

Nitrogen content has an influence on CVD productivity, as nitrogen always amplifies diamond synthesis. Adding nitrogen to hydrogen-methane plasma can increase the speed of deposition (Liang et al., 2009; Silva et al., 2009a) (Figure 3). Nitrogen is a perfect “parasite” in terms of any diamond synthesis, as it generally reduces the value of the diamond, sometimes significantly. In spite of the rise in demand for fancy colored diamonds (“Lab-Grown Diamonds – Lightbox Jewelry”; “Technology”) and quantum memory projects (Wu et al., 2016), nitrogen-free (near-) colorless diamonds (D-J by GIA classification (“Diamond Quality Factors”)) are still more sought-after for both jewelry and the field of optics and electronics.

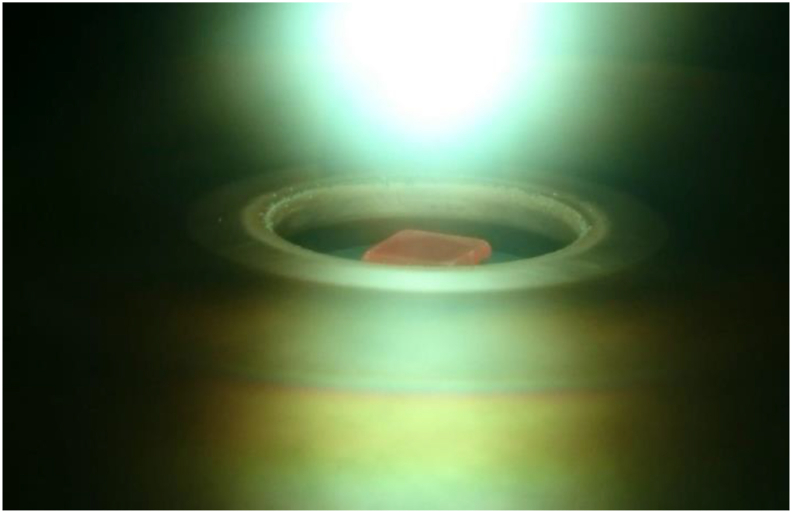

Figure 3.

Photo of growing process in CVD reactor after a few days of synthesis.

We observed that the average deposition rate of a 2.45-GHz MP CVD reactor is approximately 35 μm/h (sometimes exceeding 50 μm/h or 100 μm/h) (“Technical Specifications | ARDIS 300”) especially at the end of the cycle, but much lower at the beginning (Liang et al., 2009; Silva et al., 2009a). Following this, 1–2 days of downtime is required to reload the reactor. Based on our observations, each reactor we studied was able to synthesize, on average, 7 carats per week in a single-crystal regime (illustrated in Figures 3 and 4). There is one curious advantage of CVD synthesis: the growth of the diamond can be observed (Figure 3), which is impossible during the HPHT process.

Figure 4.

Cubic-shaped recently synthesized MP CVD diamond with parasitic polycrystalline jacket. This process is, therefore, beyond the upstream stage and has been omitted from our calculations.

Our observations are based on a relatively small MP CVD array of only 5 reactors. However, to make the estimate of hourly labor input more realistic we have based our estimate on an array of 10 reactors, as we feel that is the optimal number for a CVD array. To clarify: despite there being a positive correlation between the number of reactors and business performance, a 10-reactor unit can be run by only 1 operator, and so it can be used as the building block to construct larger arrays.

Each reactor requires servicing, including regular downtime, and all vital parameters must be controlled during the synthesis process. This means that an experienced member of staff is required to perform the following tasks:

-

•

Clean the chamber via different protocols (for hydrogen and oxygen usage) to remove all parasitic layers. If this is not done, the diamond will be impure.

-

•

Input a correctly oriented diamond seed (the Miller index (Schermer et al., 1995) should be {100} to maximize the speed of deposition), avoiding any pollution on its surface.

-

•

Start the synthesis, carefully raising the temperature and controlling the hydrogen-methane mix and the pressure (less than 1 atm) in the resonator.

-

•

Maintain the vital parameters during the whole cycle (which can last for days, weeks, or even months (if growing a polycrystalline diamond window for the International Thermonuclear Experimental Reactor (ITER) project (Thumm, 2011)).

-

•

Slow down plasma in the reactor before stopping it.

-

•

Extract the diamond and repeat the process.

All the tasks mentioned above require highly skilled professionals: there should be someone near the reactor throughout the 24/7 regime, one person should be responsible for the more complicated process of re-loading, and another person should manage all the processes, including the supply operations (e.g. methane delivery and the purchase of spare parts). Thus, if staff work 8-hour shifts, an array of up to 10 MP (or HF) CVD reactors requires at least 4 CVD operators, 1 senior grower (or head of the laboratory, in our terminology), and 1 administrator (Table 2):

Table 2.

The staff required to support an array of 10 2.45-GHz MP CVD reactors.

| Functionality | Total |

|---|---|

| Operators | 4 |

| Senior grower (head of the laboratory) | 1 |

| Administrator (supply, external operations) | 1 |

| Total | 6 |

We use the same approximation as for the HPHT process, i.e., an average of one person per reactor. Therefore, our estimate of labor input required per carat for an array of 10 CVD reactors is as follows (Eq. (3)):

| 6∗40 h worked per week/70 carat = 3,43 h worked per carat (hw/ct), | (3) |

Although some additional labor input is required to remove parasitic crystal deposits from the body of the single crystal (Figure 4), some customers prefer to perform this operation themselves in order to maximize the weight of the final polished diamonds.

3.3. Mined diamond

As mentioned in Section 1, this study focuses on the upstream part of the diamond “pipeline” other stages that add value through cutting, polishing, and marketing are beyond the scope of our research, despite their importance. For diamond mining, kimberlite ore must first be extracted, then moved to the concentrating factory. Moreover, the diamond field must be explored in advance of any mining activities. Exploration for diamonds also falls into the upstream process. However, here we exclude the input hours worked by geologists, as these figures are insignificant compared to the total hours worked to exploit the field. Exploration for a new diamond field is akin to manufacturing a new HPHT press or CVD reactor, i.e., it is a preliminary step, which is, of course, important, but is insignificant in terms of total further labor input per carat.

This study considers two diamond pipes mined by the DeBeers Group. These are Orapa and Jwaneng (“Botswana”), both situated in Botswana. In 2018, 12.2 and 11.9 million carats of diamond, respectively, were mined from these kimberlite pipes. There are 3037 and 2000 employees at Orapa and Jwaneng, respectively. Thus, the calculation of the average labor unit of these upstream diamond operations is given in Eq. (4)

| (3037Orapa + 2000Jwaneng) ∗ 40 h per week/((12.2 + 11.9) millions of carats)/52weeks) = 0.43 hw/ct, | (4) |

3.4. Summary

Summary data are presented in Table 3.

Table 3.

Comparison of discussed parameters for HPHT, MP CVD, and mined diamonds.

| Process | Origin | № of people | Labor input, hw/ct | Quality control | Productivity | Mobility | Preliminary work | Notes |

|---|---|---|---|---|---|---|---|---|

| HPHT | Nature replication | Medium | 1.83 | Medium | High | High | High | The cubic HPHT press, producing ∼23 carats of (near-) colorless average-sized diamonds per week |

| HPHT | Nature replication | Medium | 0.93 | Medium | High | High | High | The cubic HPHT press, producing ∼46 carats of (near-) colorless average-sized diamonds per week |

| 2.45-GHz MP CVD | Not natural | Low | 3.43 | High | Low | High | Low | 2.45-GHz MP reactor, with a capacity of ∼7 carats of (near-) colorless, single-crystal diamonds per week |

| Mining | Natural | High | 0.43 | Low | Very high | Very low | High | Orapa and Jwaneng Mines, Botswana, DeBeers Group, mixed size of diamonds |

The labor input of key DeBeers kimberlite pipes is significantly different from that of the artificial-diamond competitors. On average, it is necessary to spend less than half an hour of a miner’s work to obtain one carat of a diamond from the Orapa or Jwaneng pits, while it takes more than 1 or 3 h of growers' time to achieve the same, using the HPHT or MP CVD methods, respectively. We are able to modify the “classical” (OECD, 2021; Thomson and Webster, 2013; Freeman et al., 2008) labor productivity, which is measured using currency (i.e. USD), to “diamond” labor productivity (hourly, not annually), measured in carats. Obviously, this measure should be inversed to the labor inputs that we found, namely 1/1.83, 1/0.93, 1/3.43, and 1/0.43 hw/ct, to obtain the carats obtained per hour worked for HPHT, MP CVD, and the Orapa/Jwaneng pits, respectively (Figure 5).

Figure 5.

Labor productivity diagram showing how many carats of a rough diamond can be produced per worked hour, using the HPHT, 2.45-GHz MP CVD, and mining (Orapa and Jwaneng) methods.

It is important to note that mining labor input will vary for different types of deposits (alluvial, etc.). Our findings are applicable to two Botswana-based deposits. However, these two have recently been the main contributors (“Production Reports”) to DeBeers Group diamond production.

Furthermore, the MP CVD findings do not include the removal of the parasitic polycrystalline “jacket” from the single diamond crystal (Figure 4). Indeed, the mass of the polycrystalline “jacket” is not zero, and its inclusion would reduce labor input by increasing the carat weight. However, it was excluded as there is no economic demand for powder-like polycrystalline diamonds.

Сalculated labor input figures for lab-grown diamonds are only applicable to colorless diamonds, while very few mined diamonds are truly colorless. This should also be taken into consideration. Nitrogen-free diamonds are significantly slower to synthesize, which means that more labor hours are needed.

4. Discussion

We performed an in-depth analysis of one of the main contributors to operation expenditure (OpEx) in diamond production, namely, the number of people required to produce diamonds. We showed that diamond mining at the Orapa and Jwaneng mines is still the most effective way to produce diamonds in terms of labor input per carat. The HPHT method of diamond synthesis comes second, which explains its global dominance. The 2.45-GHz MP CVD technique is the least labor efficient among the three. Industrial applications of this method should therefore be focused on both management (less staff for more reactors) and innovation (raising diamond productivity per reactor).

There are positive trends for all three methods of diamond fabrication. First, the hydraulic presses used in HPHT have become bigger and smarter; the success of Russia-based company NDT in growing large diamonds is an example of this trend (DHaenens-Johansson et al., 2015). Consequently, the inner chamber can be made bigger, which would allow one to grow more diamonds per cycle. The rise of equipment productivity can reduce the labor input per carat. Currently, presses are limited to six cylinders with a maximum diameter of 1000 mm. If this diameter is increased to be several meters, the volume of the inner chamber where diamonds are grown could also be increased dramatically.

Innovations in the CVD method could also reduce labor input. Mainly, the size of the initial seed influences labors input. Logically, a larger seed is better, as it results in more carats per hour of labor worked. The synthesis of a 92 mm single-crystal diamond plate (Figure 6) by German scientists (Schreck et al., 2017) has been perhaps the most important development in CVD methods over the last decade.

Figure 6.

Schreck’s 92 mm single-crystal diamond plate (Schreck et al., 2017).

Schreck et al. (2017) grew a large plate using CVD in 2014. It is merely a question of time before this result is duplicated and scaled up in DC or MP CVD reactors. As a potential consequence, the size of lab-grown diamonds will increase dramatically. For example, two-inch-diameter high-quality free-standing diamond layers were grown on substrate, which allows step-flow growth and delamination without cracking (Kim et al., 2021). We believe that the CVD method, not HPHT, will allow for the synthesis of a record-sized diamond in the near future. There is at least one limitation to obtaining large diamonds via the HPHT method: uniform carbon convection is required when growing crystals inside the chamber. If the size of the crystal is below a dozen carats, this is not difficult, but if the size is close to hundreds of carats, carbon convection is not uniform across all zones of the growing crystal, resulting in a funnel-shape inside the large HPHT diamond. There are no such issues with the CVD method. This nuance is essential if someone were aiming to grow enormous diamonds. In other words, the CVD technology is technically more controllable, despite performing worse in terms of labor input (2.45-GHz MP CVD), as mentioned above.

Mining also has great potential for enhancing labor productivity, such as autonomous carrier trucks, robotized concentrate factories, etc. There are endless innovations, and many aspects can be improved. Despite the mining technologies being more “mature” than those based on applied physics, mining remains a very innovative industry.

5. Conclusions

In this paper, we have shared our estimates of the labor input required to obtain diamonds. According to the labor input breakdown for the HPHT and 2.45-GHz MP CVD methods, one carat of a (near-) colorless average-sized diamond requires 1.83 and 3.43 h of work, respectively. Our evaluation confirms the hypothesis that among the methods of diamond synthesis, HPHT is more productive in terms of labor input. Analysis of public reports from the global diamond producer De Beers shows that it takes approximately 0.43 h of work to obtain one carat of a diamond from the Orapa and Jwaneng mines (Botswana), the 5th and 2nd biggest diamond fields in the world, respectively. Thus, we have shown that diamond mining remains the most labor-efficient, compared to diamond production.

Furthermore, there are many technologies that could significantly decrease the labor input required for the analyzed methods; the increase in capacity of hydraulic-based HPHT presses, the availability of large initial diamond seeds for CVD, and automation innovations in mining are all good examples. These trends will have a strong impact on the diamond industry, and consequently, diamonds may find application as construction materials with unique physical properties in optics, electronics, medicine, quantum technologies, and many other fields.

Declarations

Author contribution statement

Vladislav Zhdanov: Conceived and designed the experiments; Performed the experiments; Wrote the paper.

Pavel Smirnov, Lukasz Andrzejewski: Performed the experiments; Analyzed and interpreted the data.

Julia Bondareva, Stanislav Evlashin: Analyzed and interpreted the data; Wrote the paper.

Funding statement

Stanislav Evlashin was supported by Ministry of Science and Higher Education of the Russian Federation [075-15-2020-903].

Data availability statement

Data included in article/supp. material/referenced in article.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- Ando Y., Yokota Y., Tachibana T., Watanabe A., Nishibayashi Y., Kobashi K., Hirao T., Oura K. Large area deposition of ⟨100⟩-textured diamond films by a 60-kW microwave plasma CVD reactor. Diamond and related materials, 12th European conference on diamond, diamond- like materials, carbon nanotubes. Nitrides Silicon Carbide. 2002;11:596–600. [Google Scholar]

- Babinec T.M., Hausmann B.J.M., Khan M., Zhang Y., Maze J.R., Hemmer P.R., Lončar M. A diamond nanowire single-photon source. Nat. Nanotechnol. 2010;5:195–199. doi: 10.1038/nnano.2010.6. [DOI] [PubMed] [Google Scholar]

- Botswana https://www.debeersgroup.com/about-us/our-operations/our-mines/botswana

- Bühlmann S., Blank E., Haubner R., Lux B. Characterization of ballas diamond depositions. Diam. Relat. Mater. 1999;8:194–201. [Google Scholar]

- Bundy F.P., Hall H.T., Strong H.M., Wentorfjun R.H. Man-made diamonds. Nature. 1955;176:51–55. [Google Scholar]

- DeCarli P.S., Jamieson J.C. Formation of diamond by explosive shock. Science. 1961 doi: 10.1126/science.133.3467.1821. [DOI] [PubMed] [Google Scholar]

- Deljanin B., Alessandri M., Peretti A., Åström M. NDT breaking the 10 carat barrier: world record faceted and gem-quality synthetic diamonds investigated. Contrib. Gemol. 2015:1–7. [Google Scholar]

- Devold, H., n.d. Oil and Gas Production Handbook 108.

- Dhaenens-Johansson U., Katrusha A., Moe K., Johnson P., Wang W. Gems & Gemology; 2015. Large Colorless HPHT-Grown Synthetic Gem Diamonds from New Diamond Technology, Russia. [Google Scholar]

- Diamond Quality Factors http://www.gia.eduhttps://www.gia.edu/diamond-quality-factor

- Dolmatov V.Yu. On the mechanism of detonation nanodiamond synthesis. J. Superhard Mater. 2008;30:233–240. [Google Scholar]

- Element Six . 2016. The Element Six CVD Diamond Handbook. [Google Scholar]

- Element Six|Synthetic Diamond and Tungsten Carbide Experts [Element Six] https://www.e6.com/en/home URL.

- Frank F.C., Lang A.R., Moore M. Cavitation as a mechanism for the synthesis of natural diamonds. Nature. 1973;246:143–144. [Google Scholar]

- Freeman R.B., Kruse D., Blasi J. 2008. The same yet different: worker reports on labour practices and outcomes in a single firm across countries; pp. 749–770. (Labour Economics, European Association of Labour Economists 19th annual conference/Firms and Employees 15). [Google Scholar]

- Galimov E.M. Possibility of natural diamond synthesis under conditions of cavitation, occurring in a fast-moving magmatic melt. Nature. 1973;243:389–391. [Google Scholar]

- GIA Examines Largest Known Diamond Grown using CVD https://www.nationaljeweler.com/articles/10577-gia-examines-largest-known-diamond-grown-using-cvd URL.

- Glyavin M., Sabchevski S., Idehara T., Mitsudo S. Gyrotron-based technological systems for material processing—current status and prospects. J. Infrared, Millim. Terahertz Waves. 2020;41:1022–1037. [Google Scholar]

- Hainschwang T., Notari F., Pamies G. A defect study and classification of Brown diamonds with non-deformation-related color. Minerals. 2020;10:914. [Google Scholar]

- Horino Y., Chayahara A., Mokuno Y., Yamada H., Fujimori N. High-rate growth of large diamonds by microwave plasma chemical vapor deposition with newly designed substrate holders. N. Diamond Front. Carbon Technol. 2006;16:7. [Google Scholar]

- Indian Minerals Yearbook 2019 (Vol - III : MINERAL REVIEWS) http://ismenvis.nic.in/Database/Indian_Minerals_Yearbook_2019_Vol-III_23929.aspx

- Ivanov O.A., Muchnikov A.B., Chernov V.V., Bogdanov S.A., Vikharev A.L., Butler J.E. Experimental study of hydrogen plasma etching of (100) single crystal diamond in a MPACVD reactor. Mater. Lett. 2015;151:115–118. [Google Scholar]

- Khmelnitskiy R.A. Prospects for the synthesis of large single-crystal diamonds. Phys. Usp. 2015;58:134. [Google Scholar]

- Khomich A.V., Ralchenko V.G., Vlasov A.V., Khmelnitskiy R.A., Vlasov I.I., Konov V.I. 2001. Effect of high temperature annealing on optical and thermal properties of CVD diamond; pp. 546–551. (Diamond and Related Materials, 11th European Conference on Diamond, Diamond-like Materials, Carbon Nanotubes, Nitrides and Silicon Carbide 10). [Google Scholar]

- Kim S.-W., Takaya R., Hirano S., Kasu M. Two-inch high-quality (001) diamond heteroepitaxial growth on sapphire (1120) misoriented substrate by step-flow mode. APEX. 2021;14 [Google Scholar]

- Kitaura R., Miyata Y., Xiang R., Hone J., Kong J., Ruoff R.S., Maruyama S. Chemical vapor deposition growth of graphene and related materials. J. Phys. Soc. Jpn. 2015;84 [Google Scholar]

- Lab-Grown Diamonds – Lightbox Jewelry https://lightboxjewelry.com/pages/lab-grown-diamonds

- Lab-Grown Diamonds Setting New Size Records https://www.jckonline.com/editorial-article/lab-grown-diamonds-size-records/ n.d. URL.

- Liang Q., Yan C., Meng Y., Lai J., Krasnicki S., Mao H., Hemley R.J. vol. 18. 2009. Recent advances in high-growth rate single-crystal CVD diamond. Diamond and related materials; pp. 698–703. (Proceedings of Diamond 2008, the 19th European conference on diamond, diamond-like materials, Carbon Nanotubes, Nitrides and Silicon Carbide). [Google Scholar]

- Lyu J., Wang S., Wang B., Nishimura K., Jiang N. Synthesis of multiple single crystal diamonds by DC-GD-CVD. Surf. Eng. 2019;35:91–95. [Google Scholar]

- Mankelevich Y.A., Rakhimov A.T., Suetin N.V. Three-dimensional simulation of a HFCVD reactor. Diam. Relat. Mater. 1998;7:1133–1137. [Google Scholar]

- New World Record in diamond Growing Rough&Polished. https://www.rough-polished.com/en/news/119081.html

- OECD . Organisation for Economic Co-operation and Development; Paris: 2021. OECD Compendium of Productivity Indicators. [Google Scholar]

- Palko J.W., Lee H., Zhang C., Dusseault T.J., Maitra T., Won Y., Agonafer D.D., Moss J., Houshmand F., Rong G., Wilbur J.D., Rockosi D., Mykyta I., Resler D., Altman D., Asheghi M., Santiago J.G., Goodson K.E. Extreme two-phase cooling from laser-etched diamond and conformal, template-fabricated microporous copper. Adv. Funct. Mater. 2017;27 [Google Scholar]

- Polushkin V.M., Rakhimov A.T., Samorodov V.A., Suetin N.V., Timofeyev M.A. OES study of plasma processes in d.c. discharge during diamond film deposition. Diam. Relat. Mater. 1994;3:1385–1388. [Google Scholar]

- Prahalad C.K., Hamel G. In: Strategic Learning in a Knowledge Economy. Cross R.L., Israelit S.B., editors. Butterworth-Heinemann; Boston: 2000. Chapter 1 - the core competence of the corporation∗ ∗reprinted by permission of harvard business review, May–June 1990, pp. 79–91. Copyright (1990 by the resident and fellows of harvard business college, all rights reserved; pp. 3–22. [Google Scholar]

- Schermer J.J., van Enckevort W.J.P., Giling L.J. Orientation dependent surface stabilization on flame deposited diamond single crystals. J. Cryst. Growth. 1995;148:248–260. [Google Scholar]

- Production Reports https://www.debeersgroup.com/reports/production-reports

- Schreck M., Gsell S., Brescia R., Fischer M. Ion bombardment induced buried lateral growth: the key mechanism for the synthesis of single crystal diamond wafers. Sci. Rep. 2017;7 doi: 10.1038/srep44462. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Schwander M., Partes K. A review of diamond synthesis by CVD processes. Diam. Relat. Mater. 2011;20:1287–1301. [Google Scholar]

- Silva F., Achard J., Brinza O., Bonnin X., Hassouni K., Anthonis A., De Corte K., Barjon J. vol. 18. 2009. High quality, large surface area, homoepitaxial MPACVD diamond growth. Diamond and Related Materials; pp. 683–697. (Proceedings of Diamond 2008, the 19th European Conference on Diamond, Diamond-Like Materials, Carbon Nanotubes, Nitrides and Silicon Carbide). [Google Scholar]

- Silva F., Hassouni K., Bonnin X., Gicquel A. Microwave engineering of plasma-assisted CVD reactors for diamond deposition. J. Phys. Condens. Matter. 2009;21 doi: 10.1088/0953-8984/21/36/364202. [DOI] [PubMed] [Google Scholar]

- Spitsyn B.V., Bouilov L.L., Derjaguin B.V. Vapor growth of diamond on diamond and other surfaces. J. Cryst. Growth. 1981;52:219–226. [Google Scholar]

- Technical Specifications|ARDIS 300 https://www.cvd-diamond.ru/en/specificiations/

- Technology vs monopoly. Market overview of lab-grown gem-quality diamonds. Part 1. Upstream∗ Rough & Polished https://www.rough-polished.com/en/expertise/117092.html

- Technology https://www.debeersgroup.com/about-us/our-operations/technology

- The Diamond Insight Report 2021 https://www.debeersgroup.com/reports/insights/the-diamond-insight-report-2021

- Thomson R., Webster E. Innovation and productivity. Aust. Econ. Rev. 2013;46:483–488. [Google Scholar]

- Thumm M. Progress on gyrotrons for ITER and future thermonuclear fusion reactors. IEEE Trans. Plasma Sci. 2011;39:971–979. [Google Scholar]

- Tikhomirova K.A., Tantardini C., Sukhanova E.V., Popov Z.I., Evlashin S.A., Tarkhov M.A., Zhdanov V.L., Dudin A.A., Oganov A.R., Kvashnin D.G., Kvashnin A.G. Exotic two-dimensional structure: the first case of hexagonal NaCl. J. Phys. Chem. Lett. 2020;11:3821–3827. doi: 10.1021/acs.jpclett.0c00874. [DOI] [PubMed] [Google Scholar]

- Top 8 Largest Diamonds in the World|CT Diamond Museum . Cape Town Diamond Museum; 2017. https://www.capetowndiamondmuseum.org/blog/2017/04/top-8-largest-diamonds-in-the-world/ URL. [Google Scholar]

- Vikharev A.L., Gorbachev A.M., Kozlov A.V., Koldanov V.A., Litvak A.G., Ovechkin N.M., Radishev D.B., Bykov Yu.V., Caplan M. Diamond films grown by millimeter wave plasma-assisted CVD reactor. Diamond Rel. Mater., Diamond. 2006;15:502–507. 2005. [Google Scholar]

- Welcome to Debswana [WWW Document] http://www.debswana.com/ n.d. URL.

- World’s Largest Colorless Grown diamond|New Diamond Technology http://ndtcompany.com/news_feed/news_1/

- Wu Y., Jelezko F., Plenio M.B., Weil T. Diamond quantum devices in biology. Angew. Chem. Int. Ed. 2016;55:6586–6598. doi: 10.1002/anie.201506556. [DOI] [PubMed] [Google Scholar]

- Yunin P.A., Volkov P.V., Drozdov Yu.N., Koliadin A.V., Korolev S.A., Radischev D.B., Surovegina E.A., Shashkin V.I. Study of the structural and morphological properties of HPHT diamond substrates. Semiconductors. 2018;52:1432–1436. [Google Scholar]

- Zhdanov V., Sokolova M., Smirnov P., Andrzejewski L., Bondareva J., Evlashin S. A comparative analysis of energy and water consumption of mined versus synthetic diamonds. Energies. 2021;14:7062. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supp. material/referenced in article.