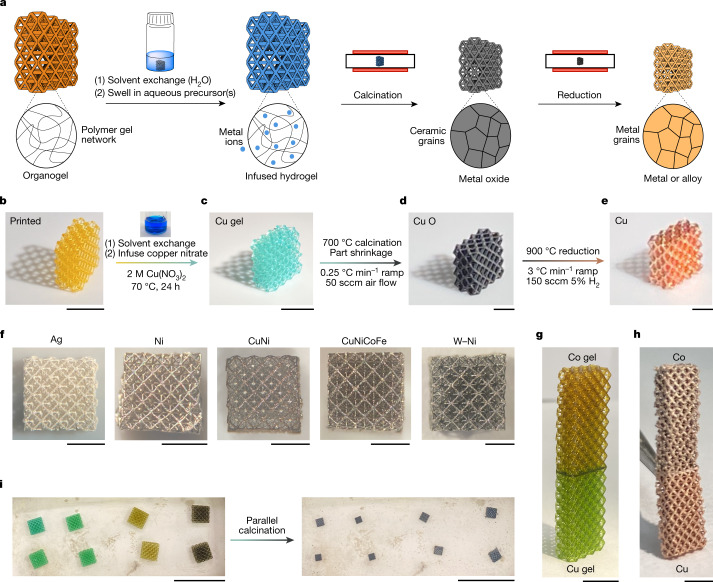

Fig. 1. HIAM process and materials.

a, Schematic of HIAM process. A DMF/PEGda-based 3D printed organogel structure is converted to an infused hydrogel replica after leaching out photoactive compounds, solvent exchange, and infusing an appropriate aqueous precursor. Subsequent calcination in air forms metal oxide structures, which are reduced to metals in forming gas. b–e, Optical images of the HIAM process for Cu metal, showing: b, printed organogel; c, infused hydrogel; d, calcined metal oxide; and e, reduced metal. f, Additional metals fabricated via HIAM including Ag and Ni, binary alloy CuNi, high-entropy alloy CuNiCoFe and refractory alloy W–Ni. g, An octet lattice infused with Cu(NO3)2 from one end and Co(NO3)2 from the other. h, After calcination and reduction, the Cu/Co gel is transformed to a Cu/Co multimaterial. i, Parallel calcination of several different infused gels. Scale bars: b,c, 5 mm; d–f, 1 mm; g, 1 cm; h, 2 mm; i, 2 cm.