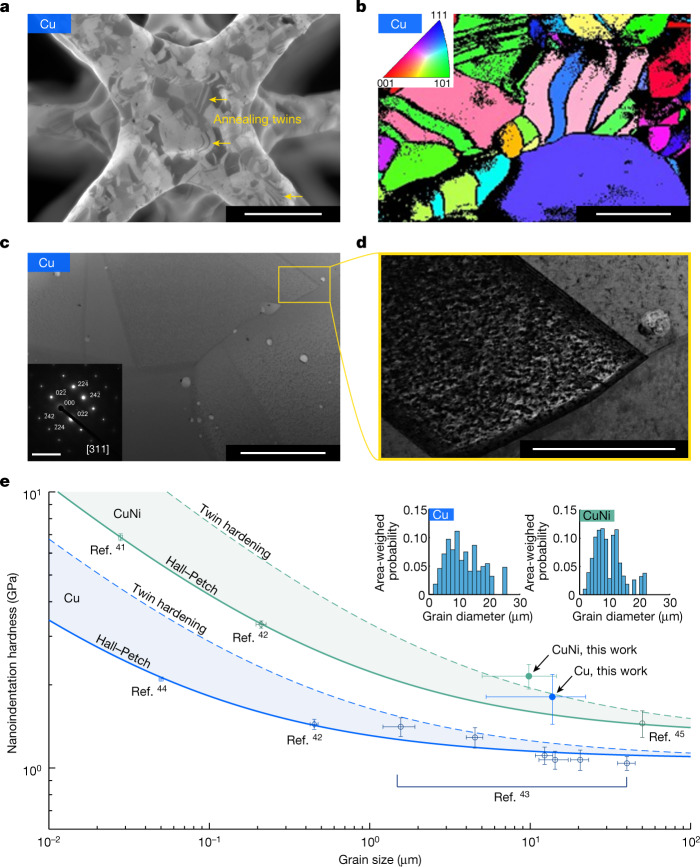

Fig. 4. Microstructure and mechanical properties of hydrogel infusion fabricated metals and alloys.

a,b, Ga+ ion-channelling image (a) and EBSD map of Cu (b) show annealing twins. Cu has a complex micrograined structure and multiple twinned regions denoted by yellow arrows. c, TEM images of Cu show well-formed grain boundaries and aluminosilicate inclusions. FCC copper is observed from the diffraction pattern in the inset of c. d, TEM image of a twin boundary and aluminosilicate inclusion. e, Nanoindentation hardness of HIAM-fabricated Cu and CuNi samples is higher than predicted based on Hall–Petch scaling (dashed lines show calculated twin-induced hardening). Error bars show standard deviations of grain size and nanoindentation hardness. Insets: area-weighted grain size distribution for Cu and CuNi. Sample sizes: Cu hardness, n = 22; CuNi hardness, n = 44; Cu grain size, n = 246; CuNi grain size, n = 309. Scale bars: a, 50 µm; b, 20 µm; c, 2 µm, inset 10 nm−1; d, 500 nm.