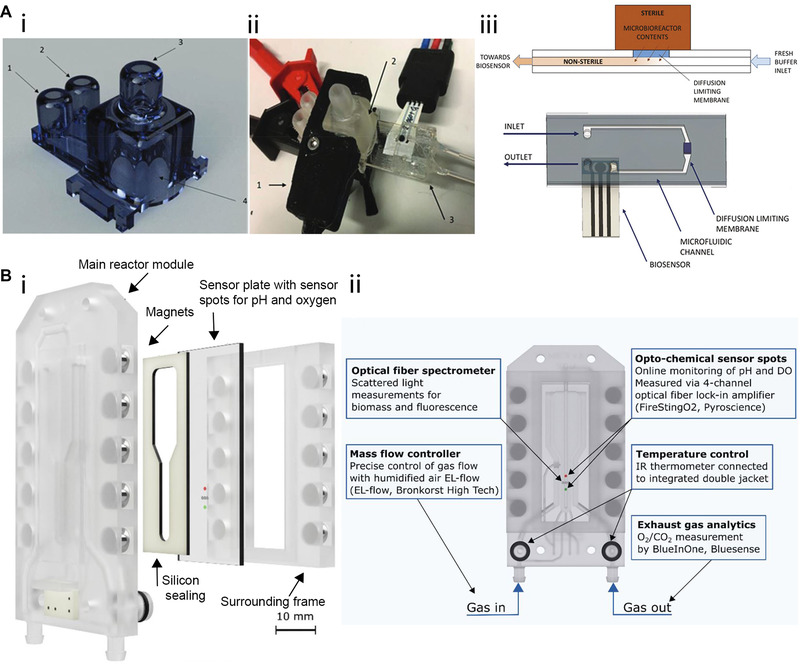

FIGURE 2.

3D‐printed microbioreactors for microbial cultivation. (A‐i) 3D‐printed microbioreactor consisting of (1) inlet (2) outlet (3) gas outlet and (4) the main reactor chamber with biosensor integration port. (A‐ii) In the experimental setup, a (1) OD sensor is clipped onto the (2) reactor chamber, and the (3) glucose biosensor is integrated. (A‐iii) Sterile integration of the glucose biosensors guaranteed by separating the microbioreactor and the biosensing unit with a diffusion limiting membrane. Adapted with permission from [48]. Copyright 2018, the Royal Society of Chemistry. Published under Creative Commons Attribution‐NonCommercial 3.0 Unported license (CC BY‐NC 3.0). (B‐i) Exploded view of the micro bubble column reactor consisting of the main reactor module, sensor plate within a surrounding frame, and silicon sealing being held together by magnets. (B‐ii) Schematic of the reactor depicting the position of microsensor spots for process analysis, gassing in‐, and outlet as well as the connectors for temperature control. Adapted with permission from [49]. Copyright 2021, the authors. Published under Creative Commons Attribution 4.0 International license (CC BY 4.0)