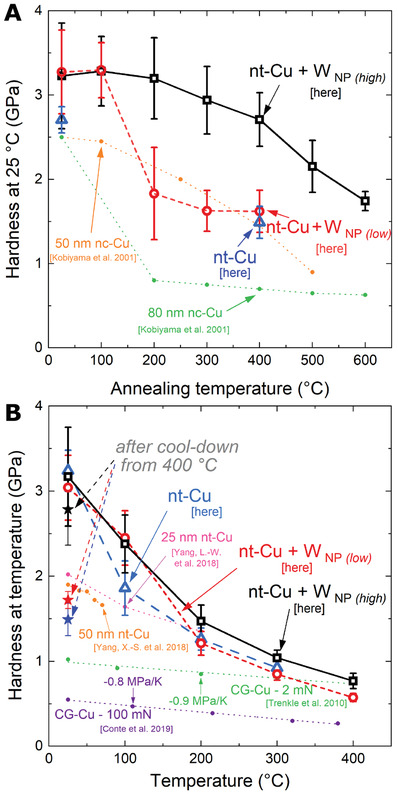

Figure 2.

Nanoindentation hardness of nt‐Cu films following heat treatments, and at high temperature. A) Room temperature hardness following successive 1 h anneals, demonstrating the mechanical stability of the nt‐Cu + 0.84 vol% W NP (“high”) condition. The pure nt‐Cu reference underwent all annealing steps, omitting selected intermediate hardness measurements. B) Hardness upon monotonic temperatures increase: a considerable drop occurs for all film compositions in 25–200 °C. Literature data from[ 15 ] is designated as CG: coarse grained (linear datafits given in B) ); nt: nanotwinned; nc: nanocrystalline; lengths indicate initial TB spacing and grain diameter, respectively. nc‐Cu data represent the extrema of performance previously identified.[ 15a ] Error bars relate the standard deviation of measured values—mainly from roughness of the as‐deposited films, which is somewhat reduced upon annealing. All indents were performed to 1 mN at a 0.2 s−1 indentation strain rate. Star‐shaped datapoints B) represent room temperature hardness upon cool‐down from the maximum temperature of 400 °C. Anneals at 500 and 600 °C were performed on separate samples as single temperature anneals.