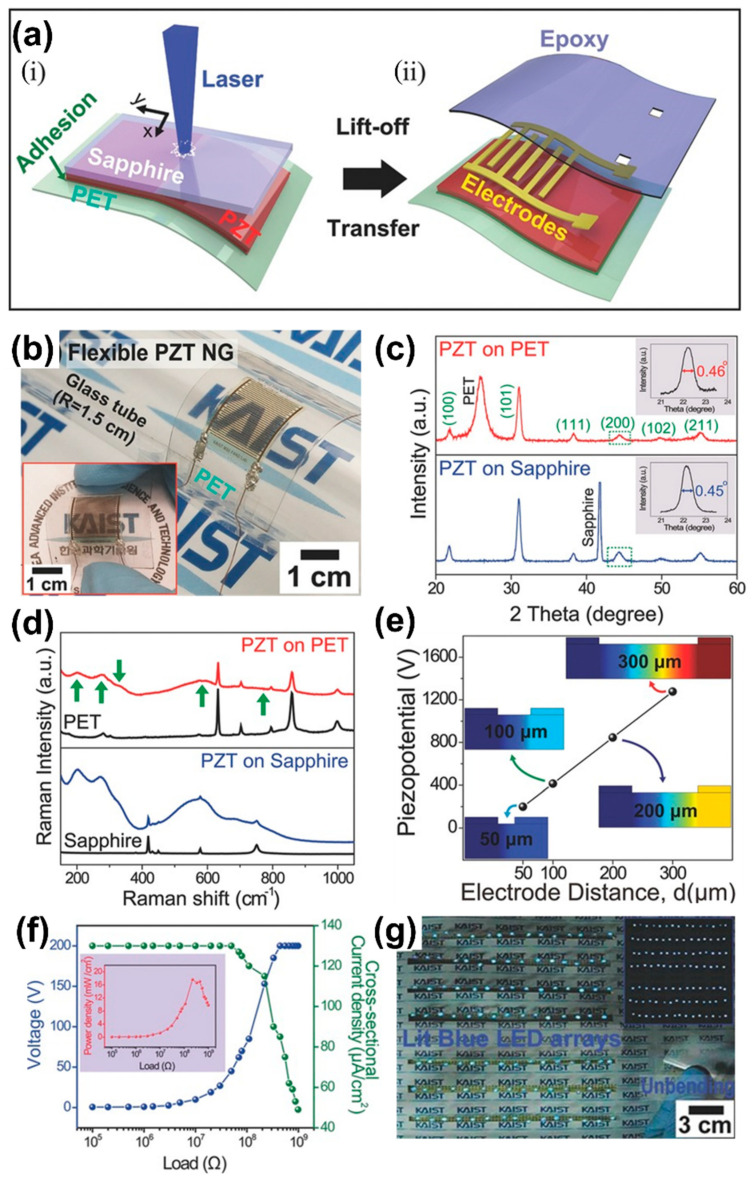

Figure 7.

(a) Schematic illustration of the fabrication process of PZT thin film harvester by LLO process. (a-i) PZT thin on transparent sapphire substrate film was transferred onto PET substrate by laser irradiation. (a-ii) Interdigitated electrodes and a protective layer were coated on PZT thin film for the fabrication of the harvesting device. (b) Flexible PZT thin film harvester attached to a glass tube and bent by fingers (inset). (c) X-ray diffraction patterns of PZT thin films on sapphire and flexible PET substrate. Magnified view of X-ray diffraction of (200) peak (inset). (d) Piezo-potential in PZT film with different electrode distances calculated by the simulation model. (e) The calculated piezo-potential in the PZT thin film varied with the distance between adjacent electrodes and increased linearly with an inter-electrode gap on the PZT film. (f) The generated voltage and cross-sectional current density of PZT generator as a function of load resistance from 2 kΩ to 1 GΩ. Output power versus load resistance (inset). (g) Photograph shows 105 lighted LEDs when the PZT film harvester was unbent by the human finger and driven LEDs in a dark room (inset). Reproduced with permission [26].