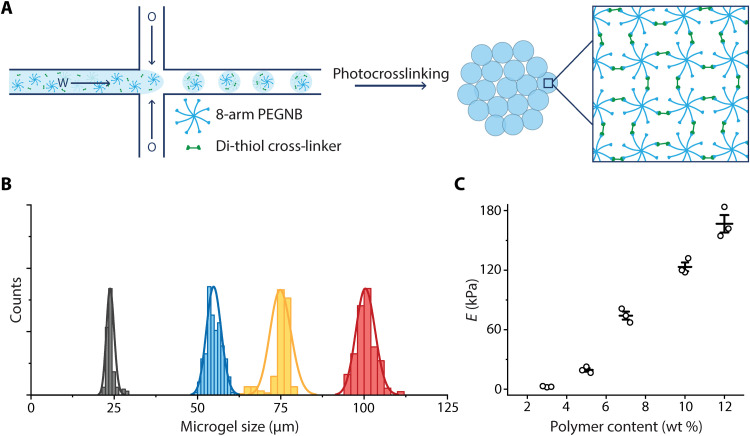

Fig. 2. Microfluidic production of thiol-ene microgels.

(A) Schematic of the microfluidic synthesis procedure. Eight-arm PEG macromers (Mn = 10,000 g mol−1) were end-functionalized with norbornene (PEGNB). Hydrogel precursor solutions containing PEGNB, DTT, photoinitiator (LAP), and droplet generation oil were injected into the microfluidic device, and aqueous droplets were produced at the flow-focusing junction. Microgels were formed by thiol-ene photopolymerization of PEGNB and DTT. (B) By controlling the microfluidic channel geometry and the relative flow rates of the aqueous and oil phases, distinct microgel sizes were achieved with low dispersity (calculated from at least 100 microgels), from left to right: Ø = 25 μm, gray; Ø = 55 μm, blue; Ø = 75 μm, yellow; Ø = 100 μm, red. (C) Stiffnesses (represented as means ± SEM, n = 3) of the hydrogels were controlled by the polymer content of the precursor solution. The measurements represent bulk network properties measured via shear rheology, which were converted to Young’s moduli (assuming ν = 0.5), and were supported by compression and nanoindentation measurements (figs. S4 to S7).