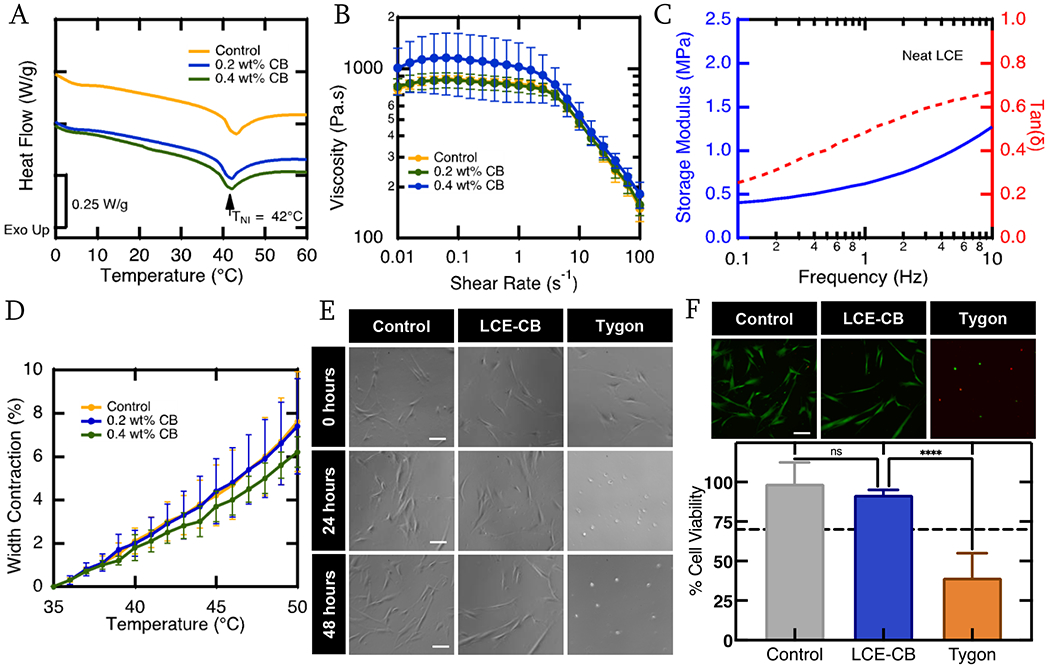

Figure 2.

Material Characterization. A) Representative DSC curves showing heat flow of LC ink without CB particles (yellow), 0.2 wt% CB concentration (Blue), and 0.4 wt% CB concentration (green) as a function of temperature. All three compositions exhibit an endothermic peak representing actuation (transition) temperature. B) Log-log plots of viscosity of the LC ink with 0 wt% – 0.4 wt% CB concentration as a function of shear rate at 38°C. C). Representative DMA curve showing storage modulus (solid blue) and tan delta (dashed red) as a function of frequency of a polydomain neat LCE sample. D) Heat actuation curve of rectangular 3D printed LCE samples with 0 wt% - 0.4 wt% CB concentration and uniaxial alignment along the short axis of the rectangle. Three samples are evaluated from three different batches for each composition (n=9). Error bars represent standard deviation. (E) Phase contrast micrographs of hDFAs at 0, 24, and 48 hours in the control, LCE extract and tygon extract media. Scale bars = 100 μm. (F) Representative fluorescent micrographs of the Live(green)/Dead(red) assay for hDFAs after 48 hours in control, LCE-CB extract or Tygon extract media. Scale bars = 100 μm. Quantification of live cell percentage for control, LCE-CB extract and tygon extract media conditions after 48 hours. Results shown are mean with standard error of mean. Statistical significance is noted as: ****p<0.0001, one way ANOVA. (n=3).