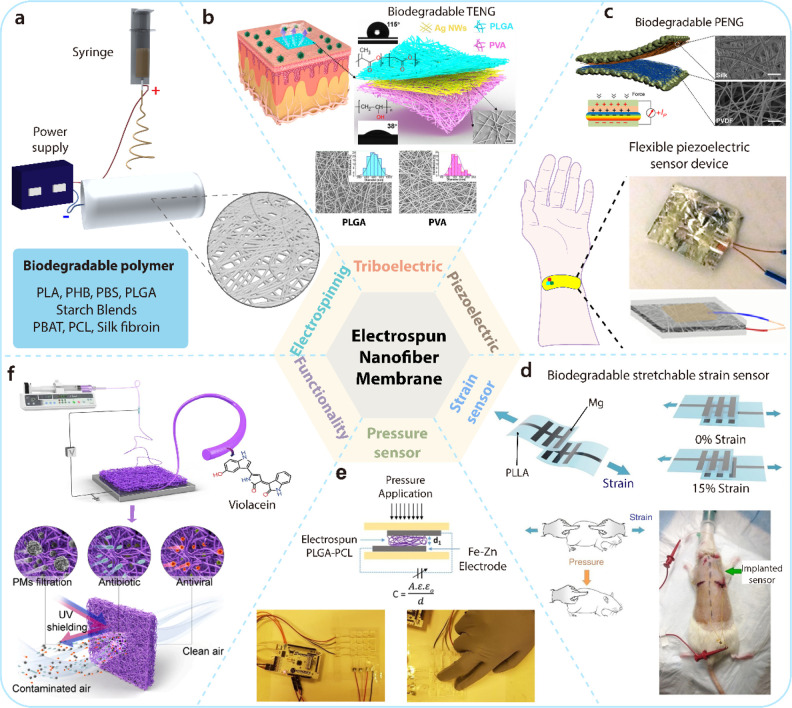

Figure 10.

Applications of electrospun nanofiber membranes. (a) Electrospun nanofiber membrane using various biodegradable polymers. (b) Schematic illustration of the 3D network structure of the all-nanofiber TENG-based e-skin and the application scenario for the e-skin can be quickly and conformally bonded to the epidermis and is porous, biodegradable, and antimicrobial.326 (c) Schematic illustration of an all-fiber hybrid triboelectric nanogenerator comprises electrodes (conductive fabric) and a triboelectric pair made of electrospun silk and PVDF nanofibers and schematic illustration of flexible sensor assembling and recording of radial artery pulse signals of a candidate. Reprinted with permission from ref (327). Copyright 2020 American Chemical Society.(d) Schematic illustration of biodegradable strain sensor. Strain sensing: When strain is applied, the two thin-film comb electrodes move about one another, causing the capacitance to change. As the strain on tendons in real life is less than 10%, the strain detecting range of 0 to 15% was chosen. Reprinted with permission from ref (332). Copyright 2018 Springer Nature. (e) Schematic illustration of a highly sensitive biodegradable pressure sensor and a commercially available pressure mapping platform coupled to a 4 by 4 array produced using a dielectric membrane and application of pressure. Reprinted with permission from ref (331). Copyright 2019 Elsevier. (f) Schematic illustration of the fabrication and properties of violacein-embedded nanofiber filter. Reprinted with permission from ref (328). Copyright 2022 Elsevier.