Abstract

Emerging sutureless wound-closure techniques have led to paradigm shifts in wound management. State-of-the-art biomaterials offer biocompatible and biodegradable platforms enabling high cohesion (toughness) and adhesion for rapid bleeding control as well as robust attachment of implantable devices. Tough bioadhesion stems from the synergistic contributions of cohesive and adhesive interactions. This Review provides a biomacromolecular design roadmap for the development of tough adhesive surgical sealants. We discuss a library of materials and methods to introduce toughness and adhesion to biomaterials. Intrinsically tough and elastic polymers are leveraged primarily by introducing strong but dynamic inter- and intramolecular interactions either through polymer chain design or using crosslink regulating additives. In addition, many efforts have been made to promote underwater adhesion via covalent/noncovalent bonds, or through micro/macro-interlock mechanisms at the tissue interfaces. The materials settings and functional additives for this purpose and the related characterization methods are reviewed. Measurements and reporting needs for fair comparisons of different materials and their properties are discussed. Finally, future directions and further research opportunities for developing tough bioadhesive surgical sealants are highlighted.

Keywords: Surgical sealant, bioadhesives, hydrogel, tough, adhesive

Graphical Abstract

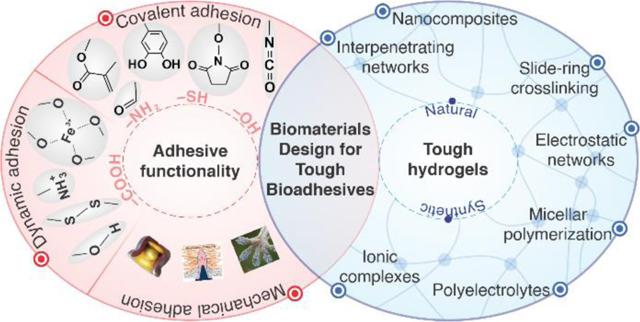

Bioadhesive hydrogels are promising candidates for sealing wounds as replacements for suturing and stapling techniques. Design of biomaterials involves introducing adhesive functionality into tough hydrogel networks.

Over ~129 million surgical procedures were performed in the US alone in 2018 (with a market value of over $14 billion); this figure is expected to rise to ~144 million procedures per year by 2023 according to MarketsandMarkets™.1 Current techniques used for surgical wound closure rely heavily on suturing and stapling. These methods are time consuming, require technical skills, cause traumatic tissue damage, and cannot immediately and effectively seal wounds.2 In particular, in organs with dynamic movement, such as the heart, wound closure is more difficult to perform.3 As such, there are increased risks of post-operation complications, such as infection. Due to the limitations associated with existing wound-closure techniques, there are unmet needs for developing new methods to manage wounds4 and lacerations of various types (i.e., surgical, incident, etc.).5

Tissue sealants and bioadhesives have gained tremendous attention due to their potential for effective wound closure and reducing post-surgery complications.6 In general, bioadhesives consist of a polymeric matrix (a hydrogel network) that are available either as a wound dressing patch,7 dry cryogel,8 or as an injectable glue. Bioadhesive patches are growing rapidly as substrates for smart bandages.9–13 Hydrogel-based sealants maintain moisture on the skin lacerations.14,15 They can offer biodegradable platforms for wound-closure purposes.16 Injectable bio-glues are fit-to-shape sealants that can conform easily to the double-curved tissue surfaces.17,18 They can interlock mechanically with the tissue in addition to providing adhesion. They can be loaded with antimicrobial and hemostatic agents, to prevent infection, to promote tissue healing, and to control hemorrhage.19 In addition, the gelation times of injectable bioadhesives are tuned simply by processing parameters based on the relevant surgical time scales. Despite the numerous advantages offered by current surgical sealants, there remain many obstacles to overcome. Recent Food and Drug Administration (FDA)-approved commercial sealants based on fibrin (Tisseel®, Evicel®, Vitagel™, etc.)20 are used for lung incisions,21 hernia repair,22 treatment of refractory chylous ascites,23 skin grafts in burn surgery,24 and cleft palate repair.24 Most commercial sealants lack sufficient adhesion strength and durability, and they are prone to induce immune responses in vivo.25

Achieving strong adhesion to wet tissue surfaces using hydrogels is a major challenge and requires deep understanding of the mechanisms involved. In general, bioadhesion in hydrogels can fail, either due to rupture in their crosslinking network (cohesive failure) or detachment at the tissue interface (adhesive failure).26 A number of studies have focused on improving cohesion in adhesive networks in terms of toughness, to prevent failure in bioadhesives.27 Bioadhesives are required to mimic the mechanical properties of native tissues and are therefore required to be strong yet stretchable and elastic. For instance, photocrosslinked biodegradable hydrogels based on gelatin derivatives such as gelatin methacryloyl (GelMA) can stretch only ~30%, whereas this figure reaches ~150–200% for collagen in skin tissue.28 Failure of bioadhesion in hydrogels can be exacerbated in wet environments due to significant loss of mechanical strength caused by water absorption.29 Several strategies have been used to toughen hydrogel networks, but they have yet to be adapted for applications in wounds.

Adhesion failure due to insufficient interactions between the hydrogel and tissue surfaces is a major obstacle in the development of bioadhesives. Many attempts have been made to endow hydrogels with durable wet adhesiveness.30,31 Efforts thus far have been focused primarily on taking advantage of mechanical interlocks as well as introducing covalent and/or noncovalent bonds with the underlying substrates.26 Nevertheless, most studies have reported adhesive strengths on the order of 101–102 kPa for hydrogel-based bioadhesives,32 which is significantly lower than the intrinsic strength of most native tissues in the human body (e.g., up to 15 MPa for skin).28 The lack of appropriate adhesion strength in recently developed bioadhesives has motivated research to explore novel biomaterials for stronger adhesion.33

Conflicting bioadhesive design requirements result in compromising one property when optimizing others.34 For instance, a high swelling ratio is desired to induce hemostasis, and thereby, stop hemorrhage rapidly,35,36 whereas the augmented swelling in hydrogels usually deteriorates adhesion strength.19,37 In many cases, enhancing cohesion decreases adhesion and vice versa.38 Hence, to choose the proper polymer network, crosslinking strategy, and adhesion mechanism for a cohesive (tough) and adhesive network, a rational design map is required to meet the specific requirements based on the intended application. As the field progresses, additional capabilities, such as monitoring biological function will be built into bioadhesive materials.39,40

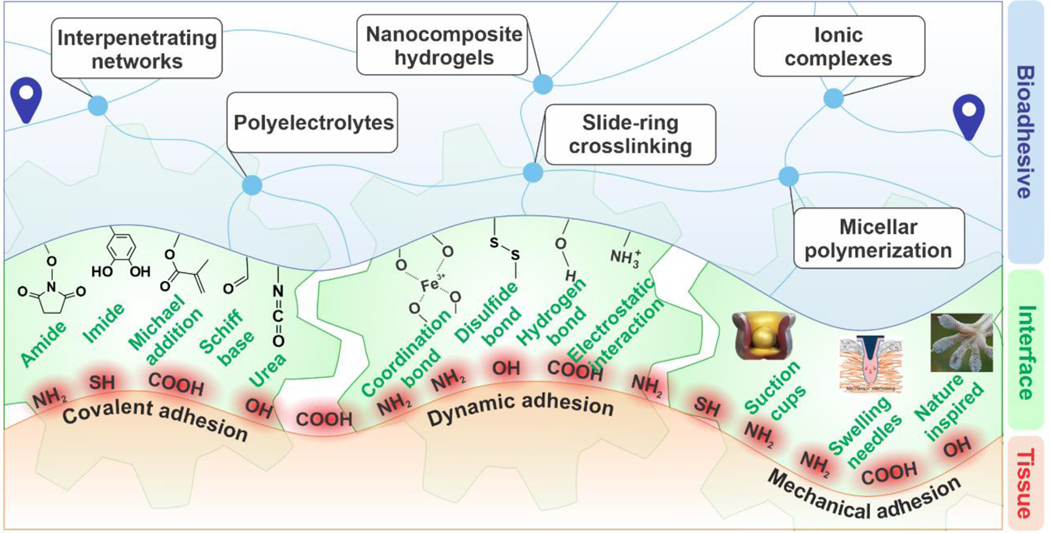

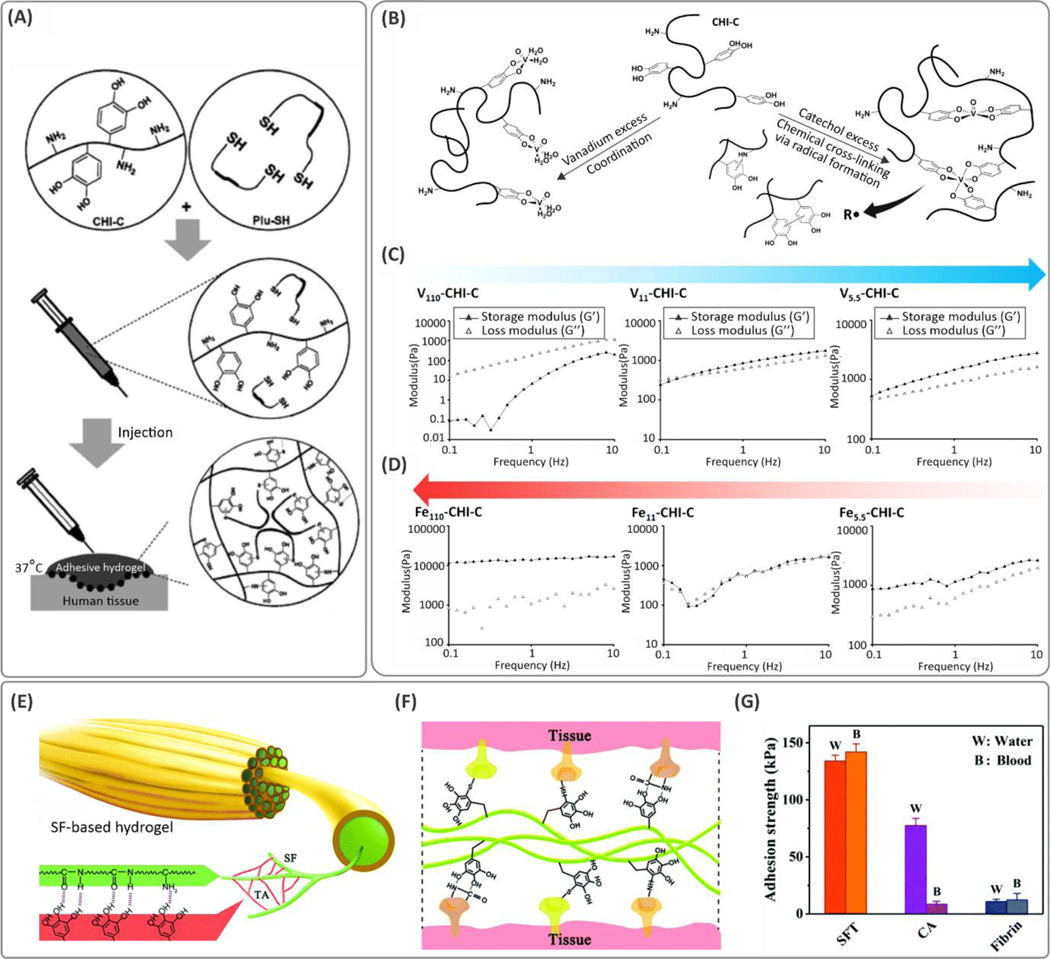

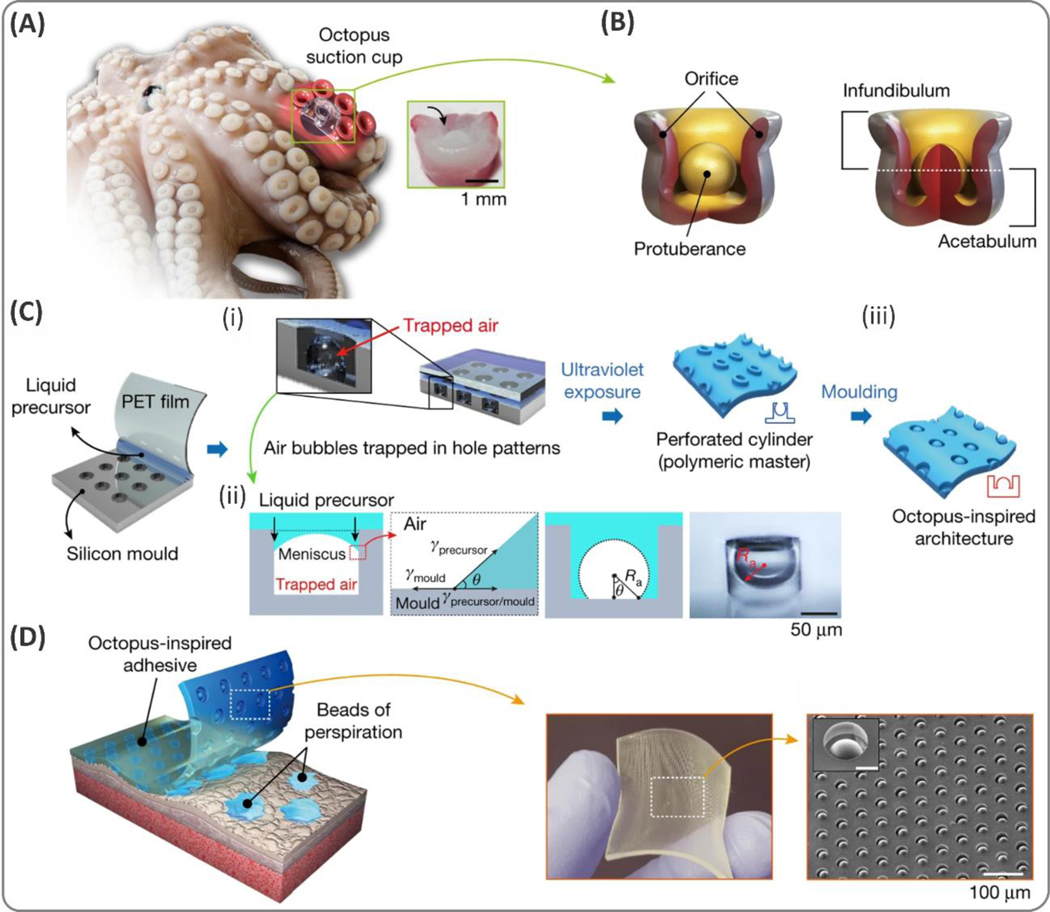

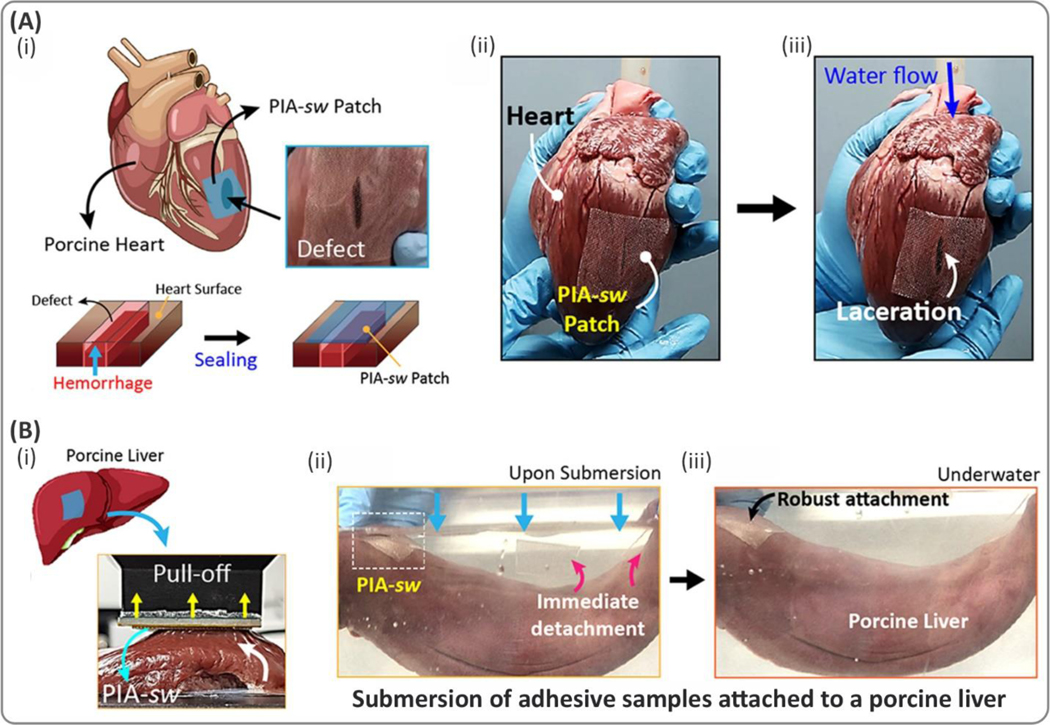

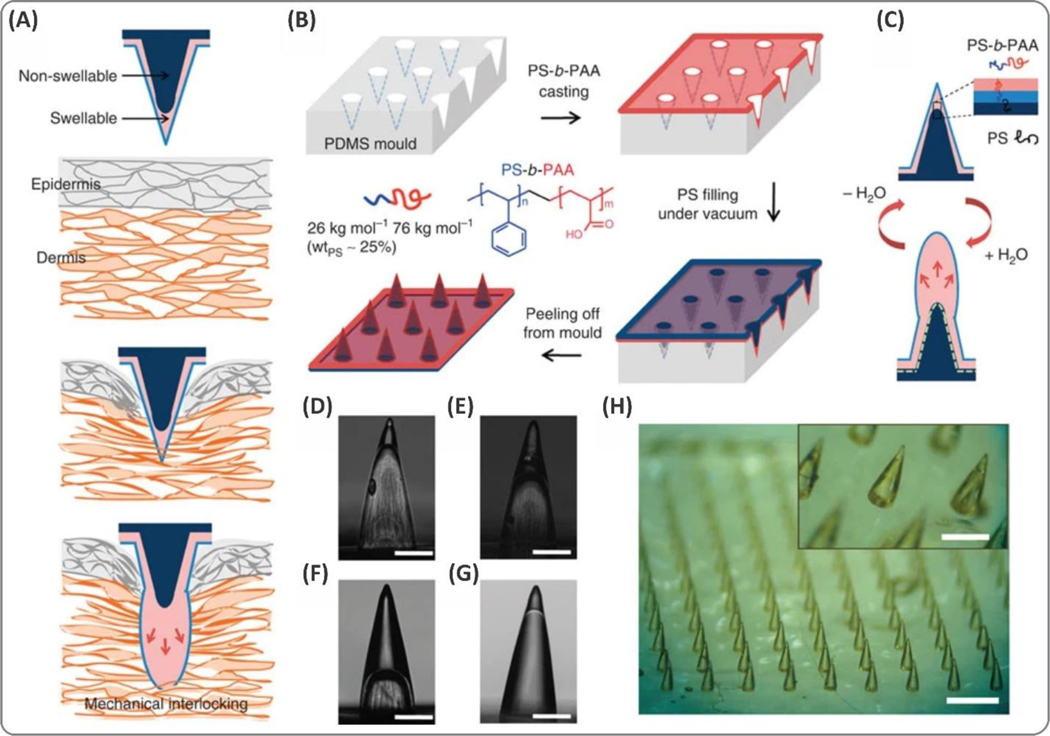

In this Review, we discuss a broad range of biomaterials and fabrication methods that serve to enhance cohesion and adhesion, along with their advantages and shortcomings. As illustrated in Figure 1, the design of bioadhesives begins with the selection of a polymer backbone and a crosslinking mechanism that supports cohesion and toughness in the material. Hence, we first cover the macromolecular strategies and various crosslinking chemistries used to engineer tough and stretchable hydrogels. Then, a variety of chemical and physical mechanisms can be used to introduce interfacial interactions for adhesion. Therefore, the subsequent sections are devoted to biomaterial types and modification procedures leveraging their bioadhesion. We discuss the measurements used to compare materials and their properties. Finally, current challenges and targets for future research and development in tough bioadhesives are highlighted.

Figure 1. An overview of the material design roadmap for tough bioadhesives.

Development of bioadhesive materials involves: (i) design for cohesion where a combination of the polymer backbone and crosslinking strategy is selected to ensure mechanical durability in a tough hydrogel, and (ii) design for bioadhesion where a mixture of covalent and dynamic interactions, as well as mechanical interlocks, are incorporated into the material design.

Cohesive biomaterials: Tough stretchable polymers

Tuning intra- and intermolecular chemical and physical interactions are essential for bioadhesives, to enhance their cohesion and adhesion. Cohesive failure refers to the early failure of polymer matrix that occurs before the tissue/hydrogel interface is damaged.41 The mechanical mismatch between the sealant and tissue is a major cause of cohesive failure. This issue is particularly observed in brittle hydrogels, as they fail to comply with the tissue deformation.42 To address this issue, bioadhesives with high stretchability and strain recovery are favored. These characteristics are reflected in so-called “tough” hydrogels.43

Most organs and tissues in the body, such as the myocardium, undergo continuous dynamic deformation. However, hydrogels, if not processed and designed properly, are rather brittle (mainly due to uncontrollable and inhomogeneous crosslinking distributions)44,45 and are thereby susceptible to failure in response to dynamic loads. Therefore, they fail mostly at much lower fracture energies than natural tissue (e.g., two orders of magnitude lower than cartilage).46 Hence, considerable effort has been devoted to tuning the mechanical properties of bioadhesives to minimize mechanical mismatches with underlying tissue.47 Soft, compliant hydrogels are of great interest to avoid early adhesion failure.42 Failure in adhesion stems primarily from the deformation resistance in stiff hydrogels. The advances made for creating tough, yet compliant and stretchable hydrogels are inspired largely by efforts made in the field of flexible electronics and stretchable wearable devices48–50 such as ultrasonic devices.51 Similar principles can be implemented for the development of mechanically robust tissue adhesives. Below, methodologies to fabricate tough and stretchable hydrogels are highlighted.

Interpenetrating multi-network hydrogels

One common approach to enhance toughness in hydrogels is to support covalent polymer networks with secondary networks that can dissipate the deformation energy via non-covalent reversible attractions. In these so-called “interpenetrating polymer networks (IPN)”, reversible dynamic bonds reform continuously once polymer chains start to break off under tensile mechanical loads.41 These double networks can also be formed via crosslinking two separate polymers with different chain lengths.52 In these networks, when mechanical loads are applied, initially, the short-chain bridging networks are first ruptured irreversibly under tension, and thereafter, the long-chain macromolecule-based networks bear larger deformations.53 Alginate, hyaluronic acid (HA), and chitosan are among the natural biomolecules used to introduce such short-chain energy dissipative networks in these hydrogel systems. Poly(acrylamide) (PAM) and poly(ethylene glycol)diacrylate (PEGDA) are the most commonly used long-chain polymer backbones used as elastic covalent networks.46,53,54

Incorporating chemical functionality that enables different crosslinking possibilities, such as covalent and ionic interactions, has leveraged tough hydrogels. The ionic crosslinks between the chains are broken reversibly during tensile deformation, whereas the covalently crosslinked network provides additional support by bridging the cracks through the dynamic molecular rearrangements.52 For example, a maximum stretchability of 23× was obtained in a PAM-alginate hydrogel due to the synergistic effects of covalent and ionic crosslinked networks. This stretchability was significantly higher than that of its constitutive components (alginate and PAM with 1.2× and 6.6× stretchability, respectively).52 Similarly, the addition of ionically crosslinked alginate within a poly(ethylene glycol) (PEG) network enhanced the stretchability of the hydrogel from ~300% to ~400% compared to control PEG samples.55 One possible drawback associated with tough double network hydrogels is the permanent rupture of the short chains and thereby high mechanical hysteresis in response to cyclic loads.56 This issue was addressed in the alginate-PEG crosslinked network, where alginate re-associates after removing the load, enabling the hydrogel to self-heal after each loading cycle.

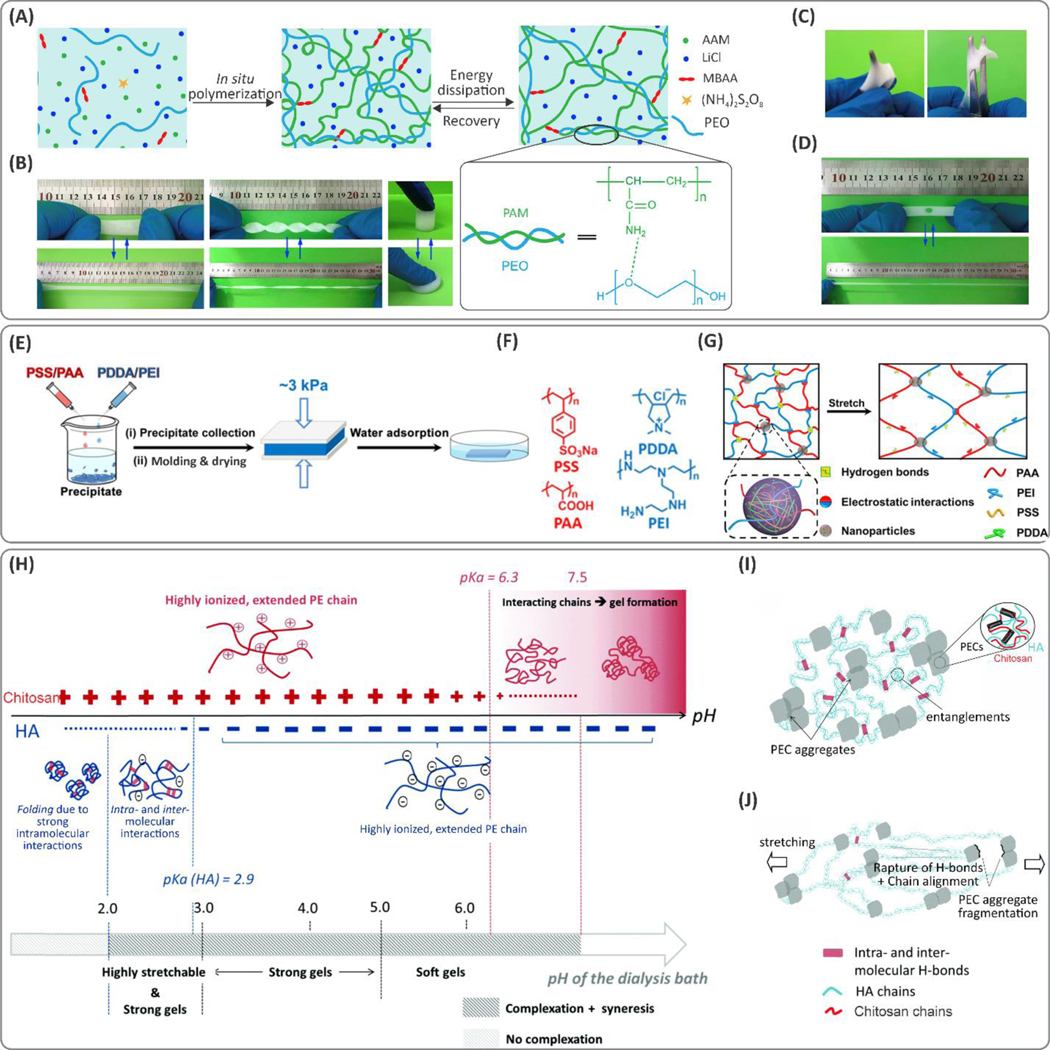

In combination with covalent networks, hydrogen bonding between two polymers also improves toughness. This effect was demonstrated in a PAM and poly(ethylene oxide) (PEO)-based hydrogel (see Figure 1A).57 The stretchability of the composite material was controlled by changing the concentration of PEO. At 8 wt.% PEO, approximately 5× improvement in stretchability was observed, compared to pure PAM. This effect was more prominent for lower molecular weight PEO due to the fewer polymer entanglements. In addition, the hydrogels were also characterized by high tear resistance (Figure 1B–D).

Copolymerization of different monomers is another simple approach to design multi-network tough hydrogels. Recently, a polymeric matrix with a pH-sensitive swelling was prepared through copolymerization of acrylamide (Aam) and acrylic acid (AA) monomers within an agar network.58 Agar is a thermosensitive linear polysaccharide that forms a gel below 35 °C. Integration of agar within poly(Aam-co-AA) network led to a pH-sensitive tough hydrogel (stretchability on the order of 1500%) with tunable mechanical properties.

Interactions between two oppositely charged polymers drive another class of double-networked stretchable and tough hydrogels. For instance, strong electrostatic complexation of positively charged poly(diallyldimethylammonium chloride) (PDDA)/branched poly(ethylenimine) (PEI) and negatively charged polyelectrolyte mixture of poly(sodium 4-styrenesulfonate) (PSS)/poly(acrylic acid) (PAA), led to tough and stretchable (the maximum strain at the break of ~2400%) hydrogels (Figure 1E–G).59 The stretchability of the hybrid hydrogel was tunable by modifying the concentrations of the chemical constituents (i.e., the PDDA-PSS to PEI-PAA ratio). In addition to electrostatic interactions, in situ formation of PDDA-PSS nanoparticles within the PEI-PAA crosslinked chains introduces dynamic hydrogen bonding, which improves the mechanical properties of the synthesized biomaterial (Figure 1G). In another study, coacervation of natural bio-polyelectrolytes, such as the mixture of chitosan and HA in NaCl solution (due to syneresis, the expulsion of liquid) led to highly stretchable hydrogels.60 The hydrogels were developed by desalting the mixture of chitosan and HA under different dialysis pH conditions. Changing the pH from the pKa of amine groups in chitosan (6.3) to the pKa of carboxylic acid in HA (2.9) during the dialysis process led to improvement in hydrogel stretchability (Figure 1H). At low pH (<3), HA molecules fold due to strong intra- and intermolecular interactions, while chitosan chains form extended conformations (Figure 1I,J). Thus, hydrogen-bonding interactions within the folded network of HA acted as energy-dissipating components improving the cohesive strength of the hydrogel.

Ionic hydrogels

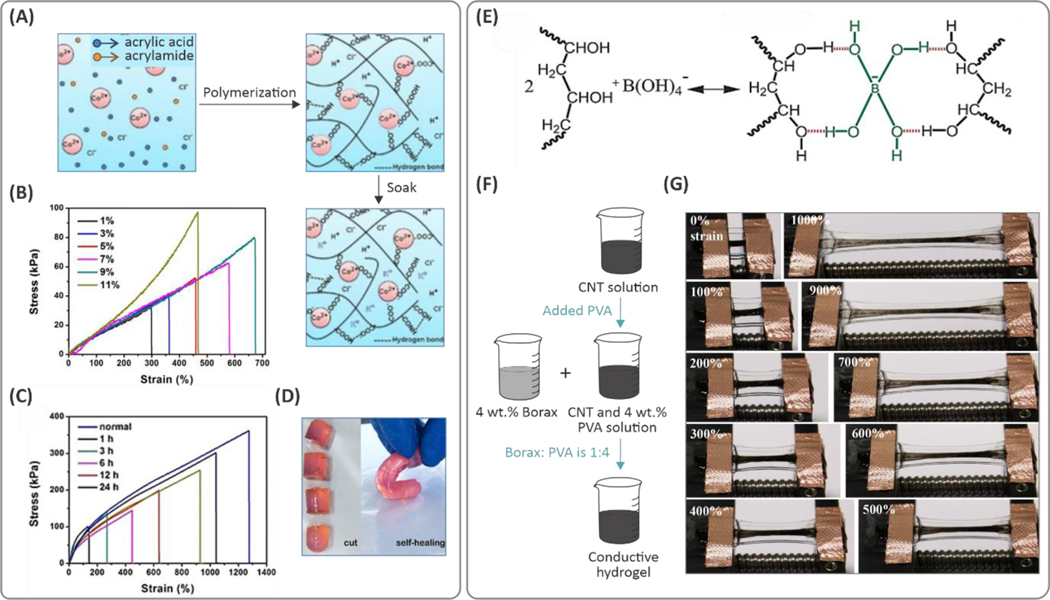

Electrolytes have shown improvements in the stretchability of hydrogels by introducing dynamic ionic and dipole-dipole interactions. Such ionic hydrogels are electrically conductive, in addition to their mechanical stretchability, which is important in wearable and implantable devices.61–63 Improved stretchability in ionic hydrogels is attained due to dynamic ionic interactions.64 For example, poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF)‐co‐hexafluoropropylene (HFP) polymers with high HFP content (i.e., 45 wt.%) served as highly polar polymers that can be easily crosslinked upon the addition of an ionic liquid (i.e., imidazolium).64 The strong, reversible interactions between the polar groups on the polymeric chain and the ionic salt resulted in polymeric matrices with stretchability on the order of 5500%, while the lower ionic liquid concentrations showed stretchability of ca. 1000%. Here, the deformation of the material was fully reversible for strains smaller than 50%. Higher levels of strain reversibility (up to 100% strain) were obtained in ionic hydrogel systems composed of physically crosslinked poly(vinyl alcohol) (PVA) in NaCl solution.65 In this hydrogel, hydroxypropyl cellulose (HPC) drew in Na+ and Cl- ions, leading to high ionic conductivity. The addition of HPC (16 wt.%) led to lower PVA crosslinking density. Hence, an ion-rich, porous PVA network with improved stretchability up to ~800% (from ~550%) was achieved. Variation of the NaCl concentration, from 0 to 5 M, increased the hydrogel stretchability from 300% to 850%. Stretchable hydrogels enabled by ion-dipole and dipole-dipole interactions were synthesized by using an ionic liquid (i.e., 1-ethyl-3-methylimidazolium dicyanamide ([EMIm][DCA])) that also led to high electrical conductivity in the hydrogels.66,67 The ionic liquids composed of [EMI][DCA] were used to develop a new type of hydrogel matrix where polymerization of 3-dimethyl and AA monomers was propagated in the presence of methacryloyloxyethyl ammonium propane sulfonate (DMAPS). This process resulted in dipole-dipole interactions between pendant zwitterionic functional groups and resulted in stretchability on the order of ~800%. Copolymerization of AAm and AA in the presence of CoCl2 demonstrated a similar effect (see Figure 3A).68 In this case, the hydrogel showed stretchability of greater than 1200%. Additionally, increasing the Co2+ concentration led to increased stretchability, from 300% to 700% (see Figure 3B,C). This stretchability was due to strong ionic interactions between Co2+ ions and the carboxylic groups present in the polymeric backbone that act as dynamic crosslinking points. The addition of Co2+ also enhanced the self-healing of the hydrogels (Figure 3D). Integration of other ionic liquids (e.g., 1-ethyl-3-methylimidazolium ethyl sulfate) with PAA and a polyzwitterionic macromolecule, poly(3-dimethyl(methacryloyloxyethyl) ammonium propane sulfonate) (PDMAPS) has been shown to form strong hydrogel networks.69 In this study, the hydrogel was reinforced by the ion-dipole interactions due to the ionic liquid, leading to stretchability ranging from 2000% to 100,000%, at different ionic-liquid-to-PDMAPS ratios. We attribute the low stretchability and the high elastic modulus in the absence of IL to dipole-dipole interactions (due to the ion-rich sites of the polyzwitterionic chain). Here, the addition of ionic liquids reduced Coulombic interactions, which results in enhanced stretchability (at 1:2 molar ratio of ionic liquid:PDMAPS). However, excess ionic liquid content leads to imperfect binding and uncontrolled interactions between the ionic liquid and polyzwitterionic macromolecules, degrading mechanical properties.

Figure 3. Engineering tough and stretchable ionic hydrogels.

(A) Processing scheme for the ionic hydrogels based on poly(acrylic acid‐co‐acrylamide)/CoCl2 composition. (B) Effect of the Co2+ concentration on the tensile mechanical properties of the hydrogels. (C, D) Self-healing properties of the hydrogels and mechanical properties of the healed hydrogels at different time points. Reprinted with permission from ref 68. Copyright 2019 American Chemical Societ€(E) Fabrication procedure of the carbon nanotubes (CNT)/poly(vinyl alcohol) (PVA) hydrogels with borax to form the PVA complex through (F) attraction of borax to the hydroxyl groups of the PVA chain. (G) Tensile deformation of the hydrogel by 1000%. Reproduced with permission from ref 71. Copyright 2017, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim.

Recently, a physically crosslinked PVA-based hydrogel was crosslinked through hydrogen bonding between hydroxyl groups on the polymer chains.70 Here, crosslinking in the presence of H2SO4 increased stretchability up to 380%. To enhance the stretchability of the synthesized PVA-based hydrogel, salts of a weak acid (e.g., borax), were introduced to the system to interact with the tetrafunctional borate ions and hydroxyl groups of PVA macromolecular chains (Figure 3E,F).71 The hydrogels showed stretchability of up to 1000% at 4 wt.% PVA concentration (Figure 3G).

Macromolecular modulation of crosslinkers and monomers

The chemical structures of the monomer units in single-component hydrogel systems play key roles in their mechanical properties. Many studies have examined the effects of polymerization processing parameters and monomer structure on mechanical properties. Chemical functionalization of the macromolecules, e.g., with allyl and methacryloyl groups, enables crosslinking through radical polymerization reactions in the presence of chemical initiators.72 For instance, modification of cellulosic biomaterials with allyl glycidyl ether led to crosslinkable allyl cellulose.73 Polymerization of allyl cellulose in NaOH/urea solution using an ammonium persulfate (APS) initiator led to the stretchability of 126% (as opposed to <100% for those of unmodified cellulose hydrogels).74

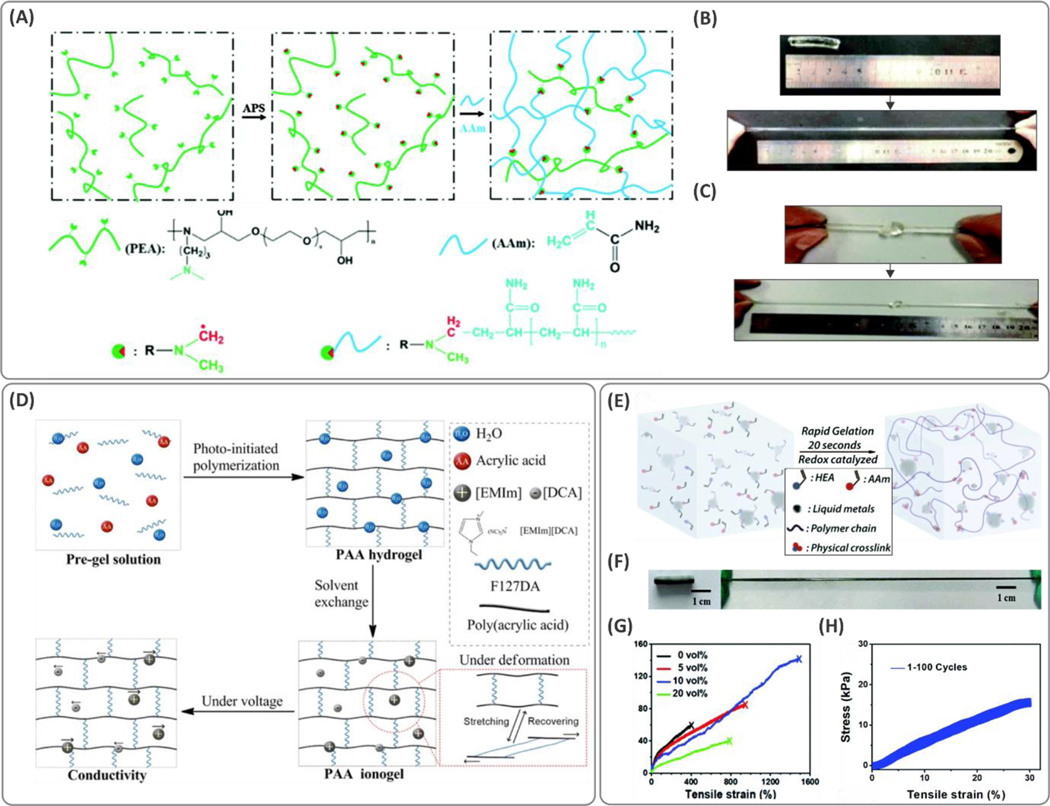

The tertiary amine groups present in aliphatic amines such as N,N,N’,N’-tetramethylethylenediamine (TEMED) can catalyze the chemical reaction with APS through electron transfer, producing free radicals for polymerization at room temperature. Redox polymerization enabled by introducing the tertiary amine on the monomer itself enhances stretchability.75 By conjugating aliphatic amine functionality on the monomer backbone or the crosslinker, the crosslinking sites can be distributed more homogenously, leading to tough hydrogels. Figure 4A shows a polymeric network containing polyetheramine (PEA) and a linear epoxy with covalently grafted tertiary amines. The grafted tertiary amines enable the polymer molecule to act as an initiator during the radical polymerization process. Finally, polymerization of PEA along with PAM leads to a highly stretchable (up to 2000%) hydrogel and strain recovery for strains smaller than 1000% (Figure 4B, C), which was significantly larger than that of PAM hydrogels.

Figure 4. Creating tougher hydrogels through functionalization of the crosslinker and polymeric backbone.

(A) Functionalization of polyetheramine (PEA) with tertiary amines allowed the polymeric backbone to act as both the initiator and crosslinker during the radical polymerization in the presence of poly(acrylamide) (PAM) network. (B, C) Tough and stretchable hydrogels were obtained with stretchability of up to 2000%. Reproduced with permission from ref 75. Copyright 2016, Royal Society of Chemistry. (D) Schematic illustration of the synthesis and deformation mechanism of poly(acrylic acid) (PAA) hydrogels crosslinked with Pluronic F127 (F127DA). Ionogels were fabricated by adding ionic liquid 1-ethyl-3-methylimidazolium dicyanamide ([EMIm][DCA]) through a solvent exchange process. The hydrogel showed high fatigue resistance for strains of up to 850%. Reprinted with permission from ref 66. Copyright 2019 American Chemical Society. (E) Rapid synthesis procedure of the liquid metal-based hydrogels acrylamide (AAm) and 2-hydroxyethyl acrylate (HEA) formed via a redox catalyzed reaction. (F) Elasticity of the hydrogel and (G) the stress-strain curves showing stretchability at the optimized concentration of liquid metal (up to ~1500%). (H) Cyclic stress-strain curves of the hydrogel for 100 cycles. Reproduced with permission from ref 79. Copyright 2019, Royal Society of Chemistry.

As discussed above, the chemical structure of the crosslinker is a key factor in the hydrogel toughness and elasticity. Changing the lengths of polymer chains and crosslinkers can significantly affect the stretchability of hydrogels. Stretchable PAM-based hydrogels crosslinked using PEGDA with different chain lengths show significant increases in swelling and stretchability when longer chains of PEGDA are used.58 Similarly, a linear epoxy polymer with multiple tertiary amine sites (i.e., PEA) was designed (initiating polymerization) to synthesize a PAM-based hydrogel with stretchability as high as 2000%.75 Figure 4D illustrates a PAA polymer-based crosslinked hydrogel network synthesized with Pluronic F127 (F127DA) molecules.66 Both stretchability and strength were enhanced with increased crosslinker concentration. Although at concentrations higher than 36 mg/ml, the stretchability was found to decrease with F127DA, the strength continued to increase.

Liquid metals are employed as additives for tuning the polymerization rates and mechanical properties of hydrogels.76 Liquid metals act as redox catalysts and therefore accelerate the radical generation in APS-based radical-generation systems.77,78 Gallium indium eutectic (EGaln) (composed of 75 v/v% gallium and 25 v/v% indium) is an example of a gallium-based liquid metal, which can be introduced in hydrogel systems to enhance toughness. Encapsulation of EGaln in graphene oxide (GO) nanoparticles through coordination with Ga3+ led to crosslinking complexes that can form hydrogen-bonding and covalent interactions with polymer matrices composed of alginate and polyacrylamide. These interactions resulted in over 4× improvement in stretchability.77 Solutions of liquid metals are generally unstable in water; however, when mixed with polar monomers (i.e., AAm and 2-hydroxyethyl acrylate, HEA), they can enhance surface interactions and form stable dispersions that favor polymerization of tough hydrogel materials (Figure 4E).79 Co-gelation of the abovementioned monomers occurred within 20 s, once potassium persulfate (KPS) was added at room temperature. Tensile tests demonstrated that the hydrogels could stretch up to 1500%, as shown in Figure 4F–H (~4× higher than the control samples with no liquid metal content), confirming the potential use of liquid metals as an effective strategy for toughening the hydrogel network.

Slide-ring crosslinking

Slide-ring crosslinking is a relatively new chemical platform for introducing toughness into hydrogels.80 These hydrogels are formed of a series of pulley-shaped molecules that pass through linear polymeric chains, which can slide freely along those chains.81 This crosslinking approach reduces the stress concentration at the crosslinking sites when external deformations are applied.81 Polyrotaxane (PR) derivatives, composed of cyclodextrin polysaccharide units, are one such moiety that can slide freely along linear chains, such as PEG.81 Low concentrations (2–3 wt.%) of these pulley-shaped cyclodextrin molecules improve the stretchability of PVA hydrogels (up to ~1600% elongation at break).82

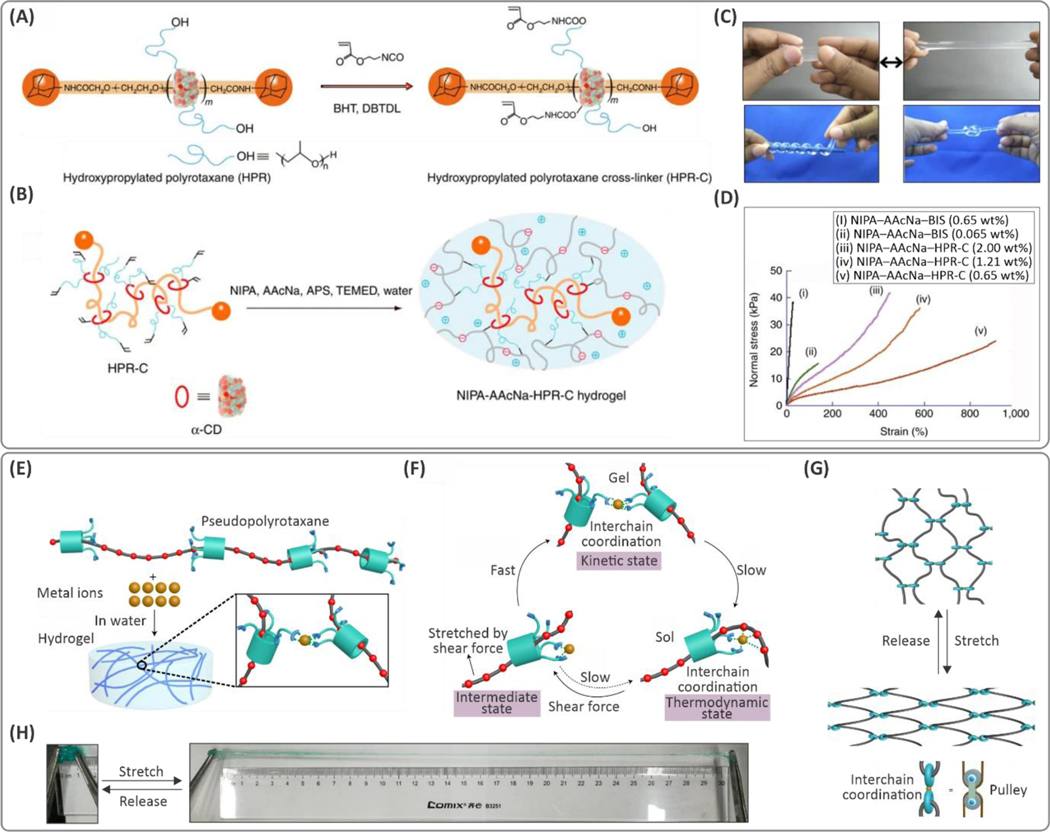

One of the main limitations of the unmodified PR however, is its poor water solubility, due to the hydroxyl-induced aggregation of the cyclodextrin molecules limiting the sliding effect of cyclodextrin along the chains.81 High pH can be used to ionize the hydroxyl groups to avoid cyclodextrin aggregation; however, it is not always practical to polymerize hydrogels at high pH. Recently, a tough slide-ring hydrogel with enhanced water solubility was synthesized using carboxyl-functionalized hydroxypropylated PR (HPR) crosslinkers.81 In this ionic PR-based crosslinker, PR molecules are in their expanded form at the neutral pH. As shown in Figure 5A,B, PR was modified with isocyanates (to form bonds with carboxyl groups) and vinyl groups to crosslink a poly(N-Isopropyl acrylamide) (PNIPAM) and PAA copolymer. This approach led to the slide-ring hydrogels with a maximum stretchability of ~1500%, which was significantly higher than the hydrogels crosslinked conventionally using N,N′-methylene-bis(acrylamide) (MBAA), (29% elongation at failure) as seen in Figure 5C,D.

Figure 5. Examples of slide-ring polymers to form hydrogels with improved toughness.

(A) Molecular design of a hydroxypropylated polyrotaxane (HPR) crosslinker (HPR-C) based on α-cyclodextrin (α-CD) and (B) schematic of free radical copolymerization of N-isopropyl(acrylamide) (NIPA) and sodium acrylic acid (AAcNa) using the developed crosslinker. (C) Demonstration of highly stretchable and deformable hydrogels. (D) Stress-strain curves for (i) NIPA–AAcNa–N,N′-methylene-bis(acrylamide) (BIS) (0.65 wt%), (ii) NIPA–AAcNa–BIS (0.065 wt%), (iii) NIPA–AAcNa–HPR-C (2.00 wt%), (iv) NIPA–AAcNa–HPR-C (1.21 wt%) and (v) NIPA–AAcNa–HPR-C (0.65 wt%) shows the hydrogels containing the same amount of crosslinkers but different amounts of HPR-C crosslinker can stretch up to 912%, which is significantly higher than that of BIS crosslinker, (i.e., 29%). Reprinted by permission from ref 81. Nature Publishing Group, Copyright 2014. (E) Schematic illustration of the gelation via metal coordination through pseudo-polyrotaxanes. (F) The mechanism proposed for the thermal relaxation and shear-induced gelation effects. (G) Chain conformation changes with stretching the hydrogel, and (H) digital photographs of the hydrogel stretched by ~30×. Reprinted by permission from ref 84. Nature Publishing Group, Copyright 2019.

Different types of pulley-shaped molecules have been designed to tune their toughening effects. In one example, a molecule with a hydrophobic cavity and inward-facing complementary polar groups formed slide-rings with hydrophilic linear chains, such as PEG.83 The pseudo-polyrotaxane molecules can crosslink PEG networks with Cu(II) metal ions due to their chelation with carboxyl groups (Figure 5E–G).84 Gelation was triggered upon vigorous shaking (for ~30 s) because of the applied shear forces. However, the gel was transformed into the sol state for hours or days after formation, depending on the compositions of the different components. These shear-induced hydrogels showed fast self-healing and excellent stretchability (~25–30× more), when compared to controls (Figure 5H).

Micellar polymers

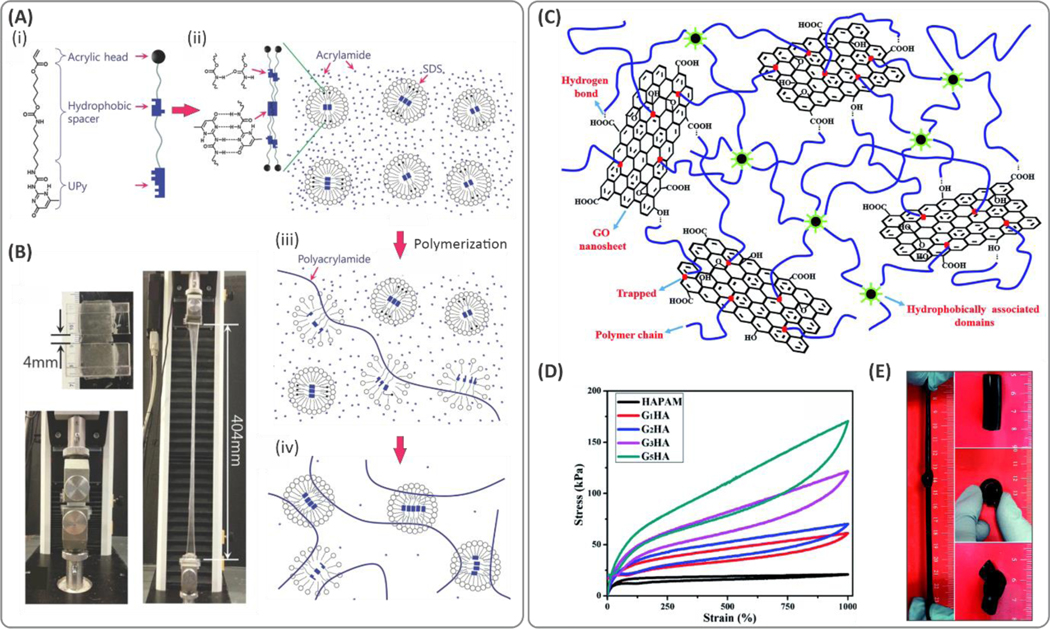

Micellar copolymerization has provided new opportunities to develop different types of stretchable hydrogels where the dynamic hydrophobic interactions between the surfactant micelles and polymer chains define crosslinking points.85 Reversible bond formation in micelles can deform, break, and reform continuously during mechanical deformation. These dynamic interactions in covalent networks lead to high stretchability in micellar polymers.86 Stable dispersions of micelles in aqueous solutions are another advantage, as they provide homogeneous and uniform crosslinking distributions throughout the polymeric backbones. Recently, highly stretchable PAM-based hydrogels (with higher than 10000% failure strain) were fabricated using a crosslinker based on hydrogen-bonding and hydrophobic associations (Figure 6A).87 The synthesized crosslinker consisted of a hydrophobic alkyl spacer that bridged a 2‐ureido‐4‐pyrimidone (UPy) tail to an acrylic head. The crosslinker molecules were encapsulated into sodium dodecyl sulfate (SDS) micelles enabling micellar polymerization of acrylamide through the SDS emulsion. The obtained hydrogels exhibited stretchability over ~100× (Figure 6B).

Figure 6. Examples of tough hydrogels created by micellar polymers.

(A) (i) Schematic illustration of the crosslinker based on hydrophobic interactions. (ii) A crosslinker that consists of an acrylic head, a hydrophobic alkyl spacer connected by carbamate, and a 2‐ureido‐4‐pyrimidone (UPy) tail (UPyHCBA) and the micelles loaded with UPyHCBA in an acrylamide solution. (iii, iv) micellar copolymerization of acrylamide using the developed hydrophobic crosslinkers. (B) Demonstration of the stretchability of tough acrylamide hydrogels stretched by 100×. Reproduced with permission.87 Copyright 2016, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. (C) Dual crosslinking mechanism in the hydrophobically crosslinked polyacrylamide (PAM)/GO composite hydrogel. Hydrophobic domains formed by the interactions between hydrophobic sides of stearyl methacrylate (SMA) and sodium dodecyl benzene sulfonate (SDBS), which led to abundant dynamic crosslinking points well dispersed within the polymer network. (D) The stress-strain curves under cyclic loads demonstrating elasticity and strain-recovery of the hydrogels. (E) Digital photographs of the hydrogel under bending, knotting, and stretching conditions. Reproduced with permission from ref 88. Copyright 2015, Royal Society of Chemistry.

Other studies have revealed the potential mechanical improvements enabled by a combination of hydrophobic interactions and secondary dynamic networks, e.g., using additives such as GO88 and PVA.89 The addition of GO in a hydrophobically associated hydrogel increased the crosslinking density through the formation of new hydrogen bonds, which further improved the toughness of the hydrogel matrix as demonstrated in Figure 6C.88 The synthesized hydrogel showed high stretchability, on the order of ~30×, and could undergo extensive deformations, (i.e., bending, knotting, etc., see Figure 6D,E).

2,4,6-Trimethylbenzoyl-diphenylphosphine oxide (TPO) is a highly efficient photoinitiator for UV crosslinking of polymers. However, the poor water solubility of TPO has limited its use. To address this issue, SDS was used to form stable TPO nanoparticle dispersions in water.90 The TPO emulsion was further used for 3D printing highly stretchable hydrogels (~1300% stretchability) from PAM-PEGDA hydrogels, which were far larger than conventionally processed hydrogels (e.g., PEGDA with ~150% stretchability). In this study, the TPO nanoparticle-dispersed emulsion improved the polymerization kinetics significantly as compared to commercially available photoinitiator, i.e., Irgacure 2959 (I2959).

Nanocomposite hydrogels

The incorporation of inorganic nanoparticles can enhance dynamic crosslinking and thereby, toughness in hydrogels.91 The high specific surface area of nanoparticles and the presence of active functional groups on their surface, facilitate their dynamic interaction with the polymer matrix. The stretchability of the polymeric nanocomposite hydrogels depends on the concentration and dispersibility of the nanoparticles, as well as the particle sizes and their chemical structures.92 The main challenge in the synthesis of nanoparticle-reinforced hydrogels is poor dispersion stability during polymerization.45 For instance, GO has a large surface area with exposed hydroxyl, carboxyl, and epoxide functional groups that facilitate various physiochemical interactions with the PAM molecules.44 Recently, hybrid nanocomposite hydrogels based on traces of GO/PAM were observed to exhibit maximum elongation at failure of greater than 3400% (i.e., a 10-fold increase compared to unmodified PAM hydrogels).44 This improvement is attributed to a variety of molecular interactions, including the combination of the hydrogen-bonding, ionic bonds, and physical interactions between the nanocomposite components. A similar combination of interactions was observed in a PAA and reduced graphene oxide (rGO)-based nanocomposite, where GO sheets functionalized with polydopamine (PDA) introduced a secondary strong ionic crosslinking point upon the addition of Fe3+ ions.93 The mechanical properties of the hydrogel were highly dependent on the concentration of Fe3+ and GO. For example, increasing the concentrations of Fe3+ and GO to 0.25 and 0.05 wt.%, respectively, resulted in reduced stretchability of the materials from a maximum of ~1250% to ~500%.

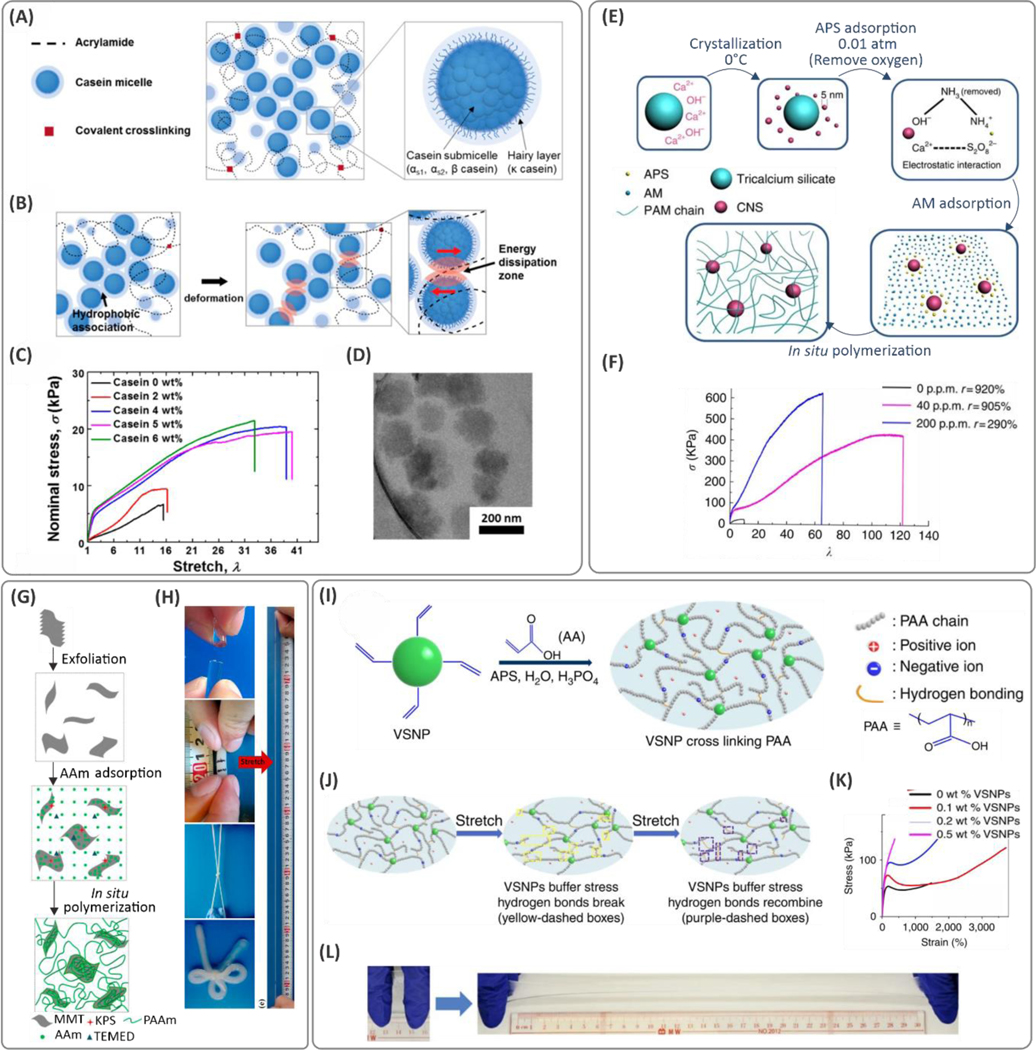

Hydrophobic interactions and plastic deformation of the micellar particles play important roles in dissipating deformation energy. Recently, a tough hydrogel was synthesized where the deformation energy dissipated through the frictional forces between the micelles (Figure 7A–D).94 In this case, casein additives, a milk-based protein molecule, formed micellar-structured nano/microparticles in water where the negatively charged hairy layer present on the surface caused repulsion and thereby a steric stabilization of the particles (Figure 7D). Polymerization of these AAm molecules in the presence of casein showed significant improvement in stretchability of the hydrogels, from 1600% to over 3500%, and increased both stiffness and strain recoverability (Figure 7C).94 In a similar study, a casein-reinforced hydrogel containing dopamine was synthesized to improve the adhesion of the material.95 Similarly, high stretchability, on the order of 1600–2900%, was obtained when different concentrations of casein (up to 37.5 wt.%) were added to the hydrogel. In contrast to the previous study, although casein additives enhanced the mechanical strength, they compromised the overall stretchability of the hydrogels. Although nanoparticle-reinforced hydrogels have shown great promise with robust mechanical properties, their release can induce cytotoxicity and thrombosis, which require close attention, particularly when considered for internal use.

Figure 7. Examples of nanocomposite (NC) hydrogels.

(A) Internal components of a casein-reinforced polyacrylamide (PAM) hydrogel, and (B) schematic illustration of the toughening mechanism of casein additives due to energy dissipation through hydrophobic interactions. (C) The tensile mechanical properties, and (D) transmission electron microscopy (TEM) images of casein micelles in the hydrogels (reprinted with permission from ref 94). (E) Fabrication process of tough nanocomposites mediated by incorporating calcium hydroxide (Ca(OH)2) nano-spherulites (CNS) in a PAM network. The Ca3SiO5 releases Ca2+ and OH- in a hydration process during which the small-sized CNS particles (<5 nm in size) are crystallized at 0 °C. The persulfate ions from the ammonium persulfate (APS) initiator are attracted electrostatically to CNS and act as crosslinkers. (F) Significant improvement of stretchability in PAM networks with small amounts of CNS. Reprinted by permission from ref 96. Nature Publishing Group, Copyright 2016. (G) Fabrication steps of montmorillonite (MMT)/PAM composite hydrogels. (H) Digital photographs of bow-tied hydrogel, and tensile stretching of the hydrogels over 12000%. Reprinted with permission from ref 99. Copyright 2015 American Chemical Society. (I) Preparation of vinyl functionalized hybrid silica nanoparticles (VSNPs)-poly(acrylic acid) (PAA) hydrogels where VSNP nanoparticles act as crosslinking points. (J) The mechanism explaining the improved hydrogel stretchability and molecular mechanism of deformation. (K) Stress-strain characteristics of the hydrogels with different amounts of VSNP nanoparticles, and (L) illustration of manually stretched hydrogels. Reprinted by permission from ref 107. Nature Publishing Group, Copyright 2015.

Hydroxide nanoparticles

The incorporation of hydroxide nanoparticles during the synthesis of hydrogels has proven to be a robust means to toughen hydrogels. Hydroxide nanoparticles introduce dynamic interactions within the polymeric macromolecules and produce reversible crosslinks within polymer networks. For instance, in a recent study, traces of Ca(OH)2 nano-spherulites (40 ppm) were used as dynamic crosslinkers for synthesizing PAM hydrogel matrixes.96 These particles were less than 5 nm in size and prepared through the hydration of Ca3SiO4. Here, the Ca2+ ions from the Ca(OH)2 nanoparticles interacted with the S2O82‐ ions released from APS (Figure 7E). Therefore, the persulfate initiator molecule (capping the chain end through free radical polymerization) favored the spontaneous ionic binding of the polymeric chains at the surface of Ca(OH)2 particles, enabling the formation of a hydrogel network. The crosslinked hydrogel showed remarkable elongation at the break, up to ~12,100% (Figure 7F), along with excellent strain recovery. The improved mechanical properties of these hydrogels were related to (1) the aggregation-free, homogeneous dispersibility of the Ca(OH)2 nanoparticles, (2) increased surface area resulting from single-digit size of Ca(OH)2 nanoparticles, and (3) optimized concentrations of the nano-spherulites, which lowered the formation of connective filaments and thereby resulted in higher pore sizes and enhanced deformability.96 In another study, the use of Portland cement, instead of Ca3SiO4 nanoparticles, enhanced the mechanical properties of the hybrid hydrogel with the maximum stretchability of PAM network, up to ~11,200%.97 In this case, similar Ca(OH)2 nanoparticles (<5 nm) were synthesized through the hydration reaction of Ca(OH)2 in the presence of a polycarboxylate-ether superplasticizer (PCE) that restricted the precipitation of the cement. The addition of 2–3 nm-sized Al(OH)3 particles instead of Ca(OH)2 nanoparticles resulted in similar properties in the materials. In this case, the presence of inorganic nanoparticles with hydroxyl groups on the surface enhanced hydrogen bonding in PAM molecules, and 2-acrylamide-2-methylpropane sulfonic acid (AMPS)-based hydrogel materials,98 and resulted in improved mechanical properties. The synthesized hydrogels were observed to have the highest stretchability, on the order of 2090% when 3 wt.% Al(OH)3 was added.

Nanoclays

One approach to improve toughness in hydrogels is to reinforce them with various nanoclays with strong surface charges. Recently, the addition of exfoliated Montmorillonite (MMT) clay particles ([(Al,Mg)4Si8O20(OH)4]Na0.66) during the polymerization of PAM (Figure 7G) led to remarkable increases in the stretchability of hydrogels, on the order of 11,800%, compared to ~40% for the PAM hydrogels crosslinked by MBAA using APS/TEMED.99 Another hydrogel with a similar chemical composition showed significantly reduced stretchability of 1290% when the polymerization reaction was carried out without TEMED.100 The chemical reaction conditions play critical roles in the hydrogel mechanical properties. Laponite® nanoclay particles, ([Mg5.34Li0.66Si8O20(OH)4]Na0.66), enhanced the mechanical properties of hydrogels. In situ polymerization of PAM with Laponite® at ~4 wt.% improved the elongation at break (stretchability up to ~5000%).101 Similar improvements were achieved through crosslinking PAM linear chains in the presence of a 60 nm double-layer hydroxide (DLH) with a chemical formula of [Mg2.52Al (OH)7](HO‐(CH2)2‐SO3)·1.27H2O.102 In this study, ionic interactions between nanoparticles and initiators led to the formation of clay‐brush particles, connecting the linear polymeric chains in an APS/TEMED crosslinking system. The electrostatic interactions involved in DLH/PAM nanocomposites were responsible for the improved mechanical properties (~3000% stretchability) of the developed hydrogel moiety at the optimum ~5 wt.% clay content. The hydrogen bonding between the clay and the initiator/catalyst system contributed to this improvement. In combination with dopamine, talc particles were well dispersed in water and facilitated the polymerization of dopamine molecules over the talc surface through partial oxidation.103 The PDA-coated talc nanoparticles were embedded within the PAM network and enabled several dynamic interactions including physical attractions between the PDA and PAM molecules, π–π stacking, and hydrogen bonding between PDA and PAM. In this case, at dopamine:AAm and talc:AAm ratios of 0.5 and 0.75%, respectively, a maximum stretchability of over 1500% was reported.

Surface-functionalized nanoparticles

Apart from the non-covalent interactions discussed above, covalent bonds between the polymer molecules and various functionalized nanoparticles can also improve toughness in hydrogels. Copolymerization with these crosslinking regulating nanoparticles is achieved primarily by nanoparticle surface functionalization with reactive functional groups such as methacrylates. For instance, silica nanoparticles were modified chemically with vinyltriethoxysilane (VTES) through a sol-gel process and covalently crosslinked with PAM chains (Figure 7I,J);104 as a result, stretchabilities over 3400% (Figure 7K,L) were reported.105 A similar approach was demonstrated to polymerize AAc monomers. In this study, the incorporation of Fe3+ ions induced reversible ionic interactions and promoted interchain associations through the chelation of carboxylic groups.106 These reversible interactions were further supported by hydrogen bonding and resulted in strain at break of 2300%,106,107 while the control PAA crosslinked material showed stretchability of up to ~1500%. Similarly, gold nanoparticles were used to serve as a vehicle to carry surface-attached double bonds across the polymeric network. In this case, N,N‐bis(acryloyl)cystamine (BAC) molecules with polymerizable alkyl groups were grafted chemically onto the gold nanoparticles. Because of chemical affinity between Au and S atoms, covalently crosslinked hydrogels were formed where crosslink points were cleavable due to the disulfide (S-S) bonds.108

Bioadhesive materials: Synthesis and characterization

After tough polymer networks are designed with a proper selection of backbone and crosslinking strategy through the methods discussed above, a variety of approaches can be employed to introduce adhesion (Figure 1). Long-lasting and strong adhesion to tissue surfaces is an essential requirement in bioadhesive sealants. The mechanical stability of the sealants depends on the synergy between the adhesion and cohesion.30 Typically, adhesive failure occurs when the inter- and intramolecular interactions within the hydrogel network are stronger than the interactive forces between the tissue and sealant material.26 This failure becomes even more of a concern when it comes to wet tissue surfaces. Furthermore, the gradual swelling of hydrogels, due to the absorption of biofluids, presents another challenge that needs to be taken into account.29

Although the underlying mechanisms of adhesion are not fully understood, adhesion is being explored rigorously through chemical covalent and non-covalent (such as hydrogen-bonding109,110 and cation-π111,112) interactions as well as physical (mechanical interlocks, tissue fusion, and topological chain entanglement113) pathways. Nucleophilic functional groups present on the tissue surfaces drive chemical interactions of the bioadhesives to the underlying tissue substrates.114,115 From a mechanical viewpoint, interlocking between the bioadhesives and uneven tissue surfaces can also favor bioadhesion.116 In this regard, ultrasound-induced cavitation in hydrogels is emerging as a means to enhance polymer entanglement with tissues for tough bioadhesion.117 In the following sections, we give a detailed overview of recent advances made in creating bioadhesive materials, and methods involved in their development. First, we introduce the testing methods used to characterize and to assess adhesion. Standard testing methods of key properties are critical to fair comparisons of materials prepared by different laboratories. Then, we discuss the chemistries involved in creating synthetic, natural,118 and bio-inspired adhesives to enhance wet adhesion in bioadhesives.

Experimental characterization of adhesive strength

Several methods have been reported to quantify the adhesive strength of hydrogels. Despite having standardized procedures to demonstrate tissue adhesion, the lack of consistency seen in the testing instrumentation and its implementation makes it difficult to compare and to evaluate the adhesive characteristics of different hydrogels. Adhesion strength values are influenced by several handling and testing factors, including the loading rate, environmental temperature, humidity and dryness (which affect the hydrogel dimensions overtime), and substrate type.30 Depending on the application and curing mechanism, a proper testing method should be selected to characterize adhesion strength. For example, photopolymerization requires illumination with light (with a certain wavelength), which may not be possible in testing adhesives that are applied between light-absorbing adherents (i.e., in a lap shear test).

Axial adhesion strength, one of the simplest methods to test the adhesion of the material, defines the maximum load that an adhesive can tolerate under tensile loading.119 In this case, the axial detachment of the adherents determines the failure point. Peeling tests reflect the normal adhesion of the materials, which can be carried out in 90° or 180° configurations.119 Another method is the burst pressure test, which simulates the seals on tissue incisions while subject to liquid pressure. Here, the stability of the sealant under increasing liquid/air pressure is measured. This test determines the origin of failure, which can be related to cohesion, adhesion, or a combination of both. The lap shear test evaluates the adhesion under shear deformations. The wound-closure test consists of filling the gap between two separate pieces of tissues or filling an incision on an integral tissue piece with an adhesive material. In this test, the tensile load applied to the tissue ends is transferred to bioadhesive in both shear (adhesive) and tensile (cohesive) modes.120

The sealing capacity of the sealants can be evaluated ex vivo by polymerizing the prepolymer on punctured tissue while flowing biological fluids at the tissue/adhesive interface to mimic the real-time sealing performance under heavy bleeding conditions.121 Given the dynamic loading applied to the tissue adhesives, looking at the cyclic decays in the above-mentioned testing platforms can be of importance. However, the cyclic response of bioadhesives has not been as thoroughly investigated as the static tests in the literature.

Synthetic bioadhesives

Synthetic polymers are synthesized using organic compounds to develop bioadhesives with the desired functionality.122 Synthetic hydrogels provide a versatile platform for introducing functional bioadhesives with thermo-responsive, electrical conductivity, and stimuli-responsive properties. For example, a thermo-responsive sealant was engineered based on the copolymerization of physically crosslinked PNIPAM and butylacrylate molecules for occluding open globe injuries of the eyewall.123 Being liquid at room temperature, the resulting copolymer enabled facile injection, which then transitioned to a solidified occlusion at (higher) body temperature. This sealant showed reversible sealing with adhesive strength comparable to cyanoacrylate glue, with no neurotoxicity nor significant inflammatory responses. Thermosensitive coacervate complex formation for bioadhesion was also demonstrated in a PNIPAM-based hydrogel containing charged polyelectrolyte moieties.124 The precursor solution was in the liquid state at room temperature and could form a nonflowing adhesive coacervate complex at temperatures above the lower critical solution temperature (LCST) (with lap shear strength on the order of ~7 kPa). Another example of temperature-driven coacervate formation with LCST was proposed by Narayanan et al.125 A protein-like polyester statistical copolymer composed of a tropoelastin-mimicking unit responsible for coacervate formation (i.e., bis(2-methoxyethyl)succinimide pendant), a catechol containing unit for adhesion, and a light-activatable mechanical strengthener was incorporated into a hydrogel for underwater adhesion over a wide pH range, 3–12. The highest adhesion strength was measured to be ~100 kPa for the optimal conditions in lap shear tests.

Synthetic approaches have leveraged bioadhesive electronics for monitoring chemical and physical signals.126–128 Implantable sensors and wireless devices129 should be adhered firmly to their target tissue to be able to function for long periods to monitor diseases.130–132 Several bioadhesive materials have been proposed for the attachment of bioelectronic devices to tissue. Zhao and coworkers fabricated a stretchable adhesive dry patch based on PAA133 that adheres to wet tissue surfaces. Here, hydrogels were formed by absorbing tissue moisture,133 as a result of which the reactive functionalities in the designed materials could interact readily with the biological surfaces to form covalent and noncovalent linkages. The PAA was functionalized with N-hydroxysuccinimide (NHS) to stabilize long-term adhesion through covalent attachment to the amine groups present on the tissue.133 A similar patch was used as a platform to develop graphene nanocomposite-based conducting adhesive patches with high electrical stability.134 These dry patches were fabricated based on origami architectures to enable their application in minimally invasive surgical tissue sealing.135 Another example involves an adhesive supercapacitor based on polyaniline (PANI), rGO, and MXenes embedded in a hybrid hydrogel based on PVA and NHS functionalized PAA.136 Here, hydrogel electrodes can bind efficiently to the biological surfaces for bio-integration of electronic systems. Synthetic patches were also designed with stimuli-responsive functionality to fabricate on-demand detachable bioadhesives.132,137–139

Many synthetic adhesives demonstrated in the literature require the use of cytotoxic procedures and hence, may not be used in biomedical applications;140 however, studies of these materials can lead to insight into the design of biocompatible medical adhesives. For instance, a creeper sucker-inspired adhesive was synthesized utilizing poly(hydroxyethyl methacrylate) (PHEMA) containing crystallizable 1-ethyl-3-methylimidazolium bromide ([EMIM]Br) solvents.141 This study highlighted that hydrogen åbonding has tremendous potential to transmit adhesion stress robustly, to enable high adhesive strengths of ~10 MPa (in lap shear test using glass substrates). Strong hydrogen-bonding-driven bioadhesives were demonstrated via coacervate formation142 as well as the incorporation of triple hydrogen-bonding clusters (THBC) in other examples.143 For the latter, a copolymer composed of N-(3-aminopropyl)methacrylamide hydrochloride (APMA) decorated with N-[tris(hydroxymethyl)methyl]acrylamide (THMA) (a branched hydroxyl-capped component) was synthesized. A so-called “load shearing” effect in the high-density hydrogen-bonding network explained the high maximum adhesion strength of ~120 kPa in a lap shear test using glass slides.

Other synthetic copolymers were developed for bioadhesion with specific functionality for a wide variety of tissues. In a recent study, a copolymer composed of AAm (for network cohesion), methyl acrylate (for hydrophobicity), AA (for mucoadhesion), and MBAA (for crosslinking) was synthesized.144 This hydrogel system was obtained through a photocrosslinking process either as an ex situ patch or in situ glue for the prevention of intestinal anastomotic leakage. Adhesion strength (lap shear test) for ex situ (~7 kPa) was significantly lower than in situ application (~12 kPa). The study found that AA plays a major role in adhesion force as increasing the AA acid content from 0 to 25 wt.% led to increases in adhesion force by over ~700%. Further increases in acrylic acid content, however, deteriorated mechanical properties. Bioadhesive powders145 were introduced for rapid hemostasis e.g., using a synthetic/natural combination of PEI, PAA, and quaternized chitosan (QCS).146 The powders were characterized by self-gelling properties (gelation in 4 s) upon contact with and absorption of blood plasma. Due to the strong adhesion (burst pressure ~ 240 mmHg), bleeding could be arrested in 10 s. Thermoplastic biomaterials such as polycaprolactone (PCL) have also shown potential for use as bioadhesives.147 These materials could be applied topically at elevated temperatures (40–50 °C, depending on the PCL molecular weight) using a glue gun.148 The star-PCL structures with carboxyl end groups were activated using amine-reactive NHS ester for bioadhesion. The proposed bioadhesive achieved ~50% of the Dermabond®’s adhesion strength (a commercial cyanoacrylate-based glue). Elastomeric bioadhesives are emerging as promising backbones due to their intrinsic toughness and stretchability. Poly(glycerol sebacate) (PGS) is one example of a degradable elastomer synthesized through condensation reactions between sebacic acid and glycerol.149 A modified PGS involving PEG chain expanders and dihydrocaffeic acid additives for adhesion was demonstrated in combination with a secondary gelatin-based network.150 Here, gelatin was modified with UPy to endow self-assembly and self-healing properties to the biomaterial. Significant improvements in adhesive strength were achieved by increasing the gelatin-UPy content (by over ~10×).

Synthetic bioadhesives, in many cases, are designed to mimic the structures of adhesive materials found in natural organisms.151 The strong hydrogen-bonding interactions in DNA molecules inspired the design of a nucleobase-modified polyphosphoester hydrogel adhesive (Figure 8A–C).152 This monomer consists of purine rings and pyrimidine functionality that introduce hydrophobic reactions as well as hydrogen bonding to the hydrogel. The resulting hydrogel is degradable under alkaline conditions; therefore, these adhesive hydrogels (maximum lap shear ~40 kPa) can be removed on demand with exposure to high pH, without leaving behind any glue residues on the tissue surface. In another study, barnacle-inspired adhesive pads were synthesized using a copolymer consisting of hydrophobic aromatic 2-phenoxyethyl acrylate and positively charged 2-(acryloyloxy)ethyl trimethylammonium chloride (ATAC).153 Mechanical toughness was achieved due to the dynamic π–π and cation–π interactions, leading to stretchability of over ~700%. The high maximum adhesion strength of 180 kPa was obtained in the axial adhesion tests for samples with hydrophobic monomer (i.e., 2-phenoxyethyl acrylate) molar fractions of 0.85, which was ~7× larger than those with 0.7 aromatic content ratio. In general, synthetic adhesives result in higher adhesion strength (in the MPa range) compared to most natural bioadhesives. In a recent study, a waterborne, synthetic yet biocompatible, and strong (~6 MPa adhesive strength) bioadhesive was proposed for dental tissues.154 Here, inspired by insect sclerotization, a cost-effective procedure based on phenol-polyamine reaction served to seal skin wounds within a few seconds.

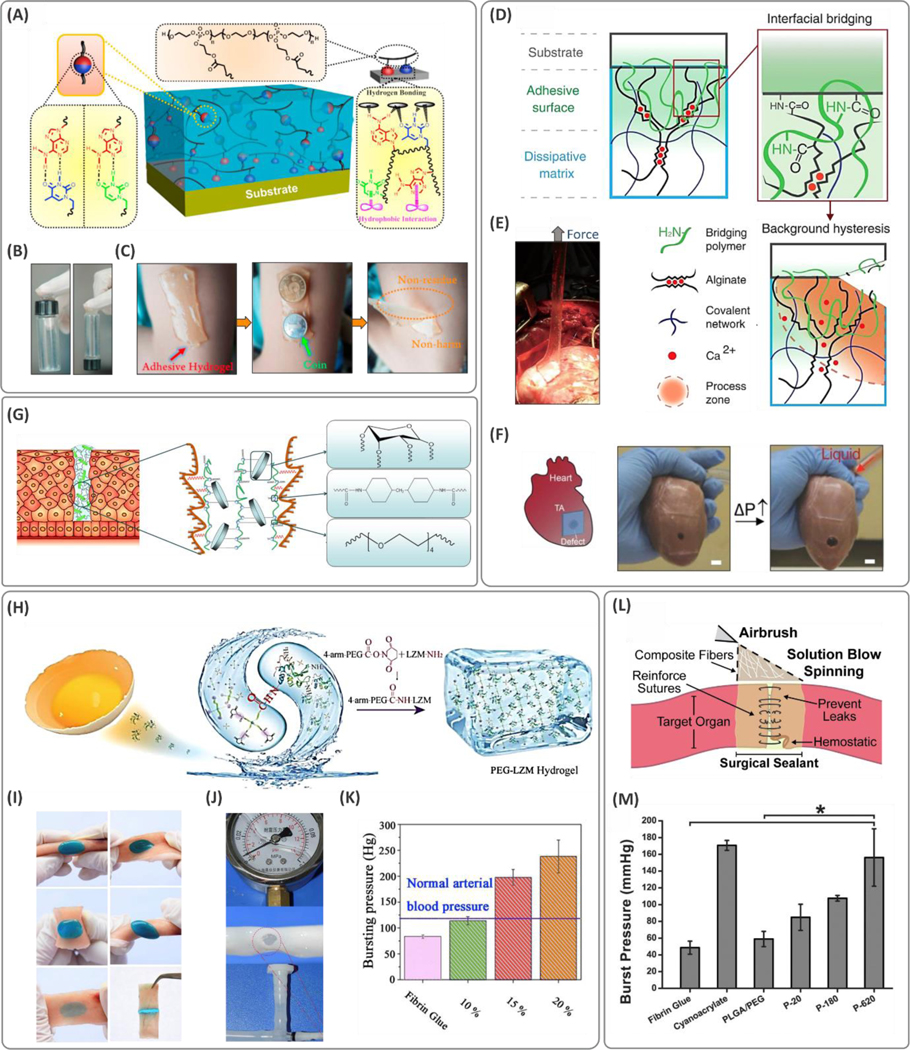

Figure 8. Methods and procedures for developing synthetic bioadhesives.

(A) Crosslinking mechanisms and the molecular interactions between the substrate leading to adhesion in nucleobase materials. (B) Demonstration of adhesion of polyphosphoesters to glass vials and (C) human skin. Reprinted with permission from ref 152. Copyright 2019 American Chemical Society. (D) Schematic of the tough hydrogels comprised of a dissipative layer matrix and bridging polymers containing primary amines, which can diffuse into the substrate and the sealant. Propagation of a crack at the tissue interface is inhibited by the energy absorbed through the dynamic ionic bonds between the calcium ions and alginate chains. (E) Illustration of the tough adhesive adhered to the myocardium tissue while peeling off, and (F) under internal pressure. Reprinted with permission from ref 157. Copyright AAAS. (G) Schematic of the xylose-based polyurethane (PU) sealant and their mechanism of adhesion. Reprinted with permission from ref 170. Copyright 2016 American Chemical Society. (H) Chemistry of adhesion in the polyethylene glycol (PEG)-lysozyme (LZM) hydrogels formed via the amidation reaction between the egg-derived lysozyme protein and 4-arm-PEG-N-hydroxysuccinimide. (I) Demonstration of the conformation of hydrogels onto the tissue under different deformation scenarios. (J) In vitro analysis of the burst tests on the porcine vessels, and (K) the burst pressure results showing that the strength values are greater than those of the normal arterial blood pressure. Reproduced with permission from ref 17. Copyright 2019, Elsevier. (L) Schematic of the composite fiber deposition on the wounded tissue using an airbrush acting as a surgical sealant. (M) Burst pressure data for the sealants show enhanced strength with increasing silica particle size in PEG/poly(lactic-co-glycolic acid) (PLGA)-based hydrogel. Reproduced with permission from ref 176. Copyright 2019, Elsevier. N-hydroxysuccinimide, NHS.

Combinations of synthetic networks with natural hydrogels are used frequently to enable biodegradation and to improve bioadhesion performance in tough hydrogel platforms.155,138 Recently, a mixture of PAM and alginate macromolecules was used to design tough hydrogel materials, which were applied to the tissue surfaces in the presence of 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDC) and NHS coupling reagents. Ex vivo adhesion energy for these materials was in the range of 300–700 J/m2.156 In another report, an adhesive hydrogel patch was developed using a covalent network containing energy dissipative alginate (tough IPN matrix) as shown in Figure 8D–F.157 This patch was treated with coupling chemicals that diffused through the hydrogel matrix and acted as a bridging layer. The bridging polymer, comprised of amine-rich macromolecules, enabled the covalent bonding between hydrogel and tissue surface through substitution reactions. Active functional groups present on the tissues favored covalent adhesion and responded spontaneously upon the application of gentle pressure on the hydrogel patch. The materials synthesized with polyallylamine and chitosan (bridging polymers) possessed the strongest adhesion when compared to PEI, collagen, and gelatin with adhesion energy on the order of 103 J/m2. This adhesion energy was significantly higher for tough PAM-alginate-based double network hydrogels when compared to the corresponding adhesion energy of individual constitutive components, indicating the substantial roles of cohesion in bioadhesion.

Topological adhesion has recently emerged as a potential mechanism for bioadhesion. In this process, polymer chains of two hydrogel networks are stitched together at their interfaces through a stitching polymer chain that can entangle within the hydrogel networks through diffusion. The diffused and entangled chains of stitching polymer are then associated together via an external trigger such as pH.113 This concept was demonstrated using a variety of synthetic hydrogels and different stitching polymers (i.e., chitosan, alginate, and cellulose) that can associate strongly and crystallize at higher pH than their pKa at the adhesion interface. Stitching (gluing) polymers can also be used to attach ex situ crosslinked hydrogels to tissues. An example of a gluing polymer developed by Gao et al. involves a PAA modified with catechol groups where entanglement and crosslinking with the backing hydrogel are triggered by NaIO4 solution.158 This bioadhesive system was able to adhere PAM hydrogels to tissue surfaces robustly (with peel-off adhesive energies of ~150–200 J/m2). Overall, synthetic approaches provide more versatility when it comes to designing multifunctional and stimuli-responsive bioadhesives.

Cyanoacrylates

Since the 1960s, cyanoacrylate-based polymers were used extensively as surgical sealants due to their high adhesion strength to wet surfaces. However, the heat generated during polymerization and the resulting toxic degradation byproducts have limited their use for internal tissues.159 Moreover, complications associated with exothermic reaction-induced tissue damage, granulomatous keratitis, glaucoma, and cataract formation have further caused concerns for the application of such biomaterials in clinical settings.160 These complications have motivated researchers to design biosafe alternatives with similar adhesive strengths. One common example of such materials includes the chemical synthesis of cyanoacrylate adhesives that express minimal toxicity. For instance, a PEG biscyanoacrylate-based bioadhesive hydrogel was used as a crosslinker in an octyl cyanoacrylate adhesive polymer.161 Here, anthracenyl cyanoacrylic acid was esterified while anthracene protected the vinyl groups. This copolymerization resulted in a cytocompatible strong and adhesive (over 200 kPa peel-off strength) material. Polymerization of allyl 2-cyanoacrylate (ACA) in mixture with poly(l-3,4-dihydroxyphenylalanine) P(l-DOPA) demonstrated biocompatible adhesives for medical applications.162 Recently, ACA was polymerized in the presence of hydroxyapatite and bisphenol-A glycidyl methacrylate (bis-GMA) to improve the biocompatibility and physical properties of the adhesive material.163 Moreover, an adhesive based on the mixture of poly(l-lactic acid) (PLLA) and pre-polymerized ACA molecules promoted wound healing and showed better biocompatibility.164 The healed tissues treated with this adhesive exhibited better tensile tearing strength compared to control samples treated with commercially available adhesives.

Polyurethanes

Polyurethane (PU) is a tough polymer, with inherent flexibility, making it a suitable candidate for sealing wounds.165 The PU macromolecules are synthesized through the formation of covalent carbamate linkage between the isocyanate functionalized molecules and a polyol (with two or more hydroxyl groups) in the presence of a catalyst or upon UV light activation.166 The flexibility and elasticity of the polymer depend on the long-chain monomers. Polyurethane and acrylate-modified PU can be designed for in vivo biodegradation.167 For this purpose, a two-step reaction, catalyzed with dibutyltin dilaurate, was designed using isophoronediisocyanate (IPDI), polycaprolactonediol (PCLD), and hydroxyethyl acrylate (HEA), where a faster biodegradation rate was attained by incorporating PCLD molecules into the PU acrylate backbone.168 The adhesion strength and gel fraction for the biodegradable polyurethane adhesive were reported to be 9 MPa and 93%, respectively. In a further study, IPDI was also polymerized with castor oil and PEG at 70 °C for synthesizing a PU-based bioadhesive material.169 The monomer ratio (-NCO/-OH) was optimized to attain strong chemical bonding interactions between the material and tissue by tailoring the distribution of -NCO groups. These groups could later couple with the amine groups of the tissue surface for covalent adhesion. Here, the curing time at room temperature was ~7–25 min and in vitro degradation of the hydrogel occurred over 7 weeks. In this study, a maximum lap shear strength of ~40 kPa and burst strength of ~30 kPa were reported for samples containing 12 v/v% castor oil. These figures dropped to ~30 and ~15 kPa when the castor oil content was reduced to 3 v/v%. Recently, hydroxyl-rich xylose monosaccharide molecules were mixed with diisocyanate molecules, 4,4′-methylenebis(cyclohexyl isocyanate) (MCI), in combination with PEG and triethylamine as a catalyst to synthesize muscle tissue adhesive (Figure 8G).170 The bioadhesive was left for 1 to 24 h in the air before the adhesion tests. Hydrogel materials had maximum lap shear strengths of 94 kPa and showed biodegradation of 20% upon incubation for 8 weeks. Inspired by mussel adhesion, catechol groups have also been introduced into urethane-based chains for improved adhesion. In a recent study, dopamine was incorporated into a polyurethane backbone.171 As a result, mechanical strength was improved from <0.05 MPa (no dopamine addition) to ~1.9 MPa. The improved cohesion also favored adhesion strength: lap shear strength was increased to ~70 kPa compared to ~30 kPa in the absence of dopamine.

Poly(ethylene glycol)

Poly(ethylene glycol) adhesives are well-established and already commercialized for use as tissue sealants (e.g., CoSeal™ and DuraSeal™). Apart from biocompatibility, PEG hydrogels are nonimmunogenic and bioresorbable. However, PEG by itself is a poor adhesive,17 and further chemical modifications are required to improve its adhesion.172 Hence, PEG polymers are processed in composite form with other components or modified chemically to tailor their physical properties for bioadhesive applications. For instance, a covalent network of polymerized PEGDA was formed in the presence of giant PEG chain networks to develop bioadhesives that could entangle spontaneously and penetrate within the substrate tissues.173 The hydrogels also promoted wound healing and reduced the immune response. Lap shear tests indicated that the use of high molecular weight PEG as a secondary network leads to adhesion strength and toughness close to those of cyanoacrylate glues. In terms of stretchability, the double network PEGDA hydrogels with high molecular weight PEG molecules exhibited a ca. two-fold increase as compared to the low molecular weight PEG.

To reduce the high swelling of PEG for bioadhesion, hyperbranched PEG-polyester polymers demonstrated robust adhesion with low swelling and improved biodegradability.37 Multi-arm PEG molecules can also improve adhesion and be used as crosslinkers in bioadhesives. For instance, cyclic succinyl ester functionalized tetra-PEG was reported to be highly reactive to amine functional groups and established covalent adhesion to the underlying tissue in a mixture with amine-capped tetra-PEG.174 Gelation in this material system occurred within 5 min compared to fibrin glue, which took over 20 min to form a gel.174 The synthesized hydrogels showed cohesive strength of ~20 kPa and burst pressure strength of up to 300 mmHg. In another study, the end group modification of an 8-arm PEG molecule with amine and aldehyde functionalities enabled an adhesive PEG polymer. Schiff base formation between the active chemical sites facilitated both crosslinking of the material and its adhesion to the tissue surface through reactions with nucleophilic amine groups (Figure 8H,I). While the gelation time was measured to be in the range of 30–75 s, the adhesion strength in the lap shear test was ~0.2× of the cyanoacrylate adhesive (Figure 8J,K). Recently, a 4-arm methacrylate capped pentaerythritol molecule was polymerized in presence of dopamine and PEGDA using Michael addition (in a dimethyl sulfoxide, DMSO, medium).175 This procedure resulted in branched hydrophobic polymers with abundant catechol end groups. Upon contact with water, these polymers form coacervates and thereby trigger adhesion to the surface (lap shear adhesion strengths of ~100–200 kPa, depending on the substrate material). This bioadhesive was effective for application in bone fracture and bleeding prevention from deep wounds.

Hybrid PEG hydrogels containing poly(lactic-co-glycolic acid) (PLGA) have shown potential for use as bioadhesives. A mixture of PEG, PLGA, and silica particles in acetone was solution blow spun onto the tissue surface (Figure 8L). The resulting sealant showed strong tissue adhesion, comparable to that of cyanoacrylate adhesives (160 mmHg burst pressure strength), as shown in Figure 8M.176 Increasing the silica particle size (from 20 to 620 nm) led to a 2-fold increase in the burst strength. Here, the larger silica particles (620 nm) suppressed crack formation and propagation, which led to improved stretchability and adhesive strength. In addition, lower swelling of hydrogel compared to CoSeal™ was reported. In another study, a mixture of PEG and PLGA polymers (both at 5 wt.%) dissolved in acetone was solution blow spun to form temperature-responsive fiber mats (~0.5–2.5 μm diameter).5 The fibers retained their fibrous form at temperatures below 31 °C. Once applied to the tissue using an airbrush, the fiber mats transitioned to an adhesive film layer, which could conform to the shape of tissues at body temperature. The pull-off tests demonstrated increased adhesion strength with the PEG concentration at body temperature, with a maximum of ~120 kPa.

Natural bioadhesives

One of the main advantages of using natural polymers for the synthesis of adhesive sealants is their innate biocompatibility and biodegradability. Hence, a surge of interest has been directed at the addition of selective chemical functionalities to natural polymeric backbones to enhance their adhesion. Although inflammatory responses induced by natural backbones such as chitosan and gelatin have raised concerns over their internal use, current research is striving to mitigate those effects while enabling their widespread as biodegradable tough bioadhesives. Below, we discuss different classes of natural polymeric backbones used for the development of adhesive hydrogel materials.

Polysaccharide-based bioadhesives

Polysaccharides are formed from monosaccharide repeating units connected through glycosidic linkages.177 Various types of natural polysaccharide-based backbones are used in bioadhesive materials, including chitosan,178 alginate,179 HA,180 carboxymethyl cellulose,181 etc. Active functional groups present in the polysaccharide backbones enable different chemistries leading to adhesive characteristics through intra- or intermolecular interactions. One of the common procedures both to functionalize with chemical moieties and to establish adhesion with tissues is to oxidize the vicinal diol groups present in their monosaccharide units that enable Schiff base formation with tissue surfaces.121 Other nucleophiles present in some polysaccharides can also be employed to graft adhesive functionalities. Below, examples of approaches undertaken to modify polysaccharide-based biomaterials for tissue adhesion are reviewed.

Hyaluronic acid

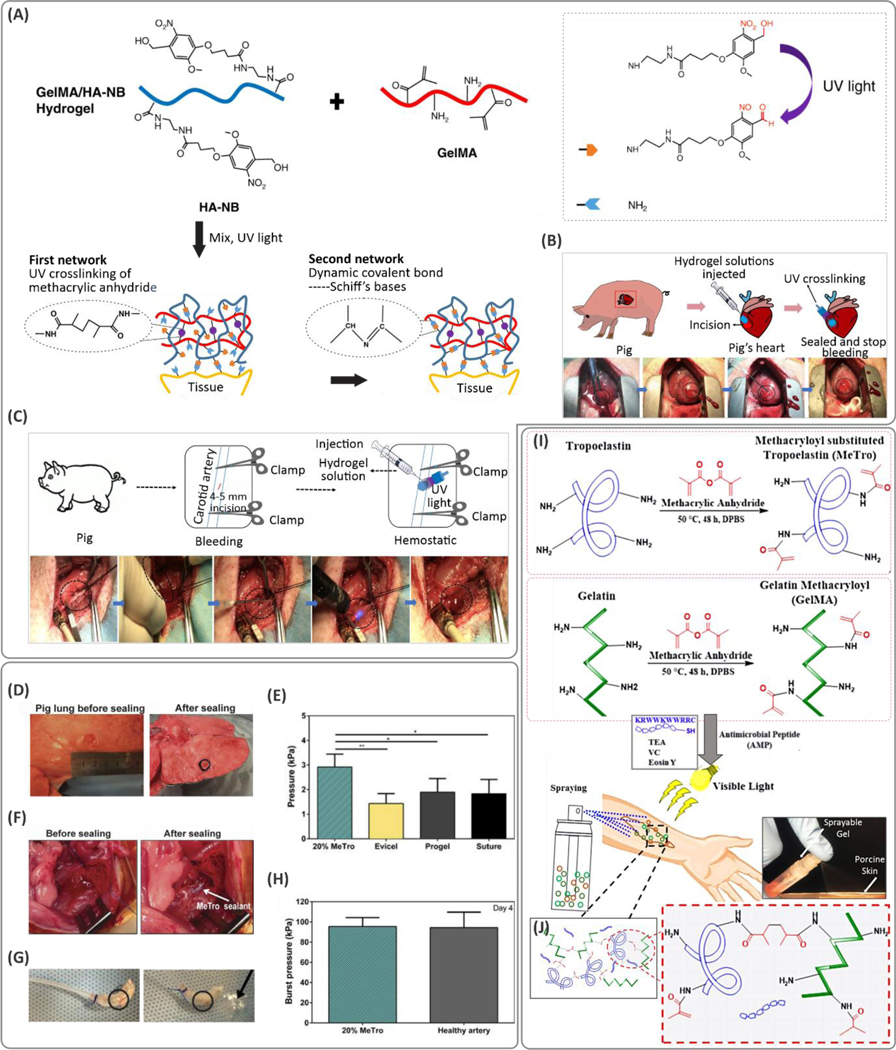

Hyaluronic acid is an immunoneutral polysaccharide that exists in the human body comprised of repeating β−1,4-d-glucuronic acid and β−1,3-N-acetyl-d-glucosamine disaccharide units.182 Many biological functions and cellular activities rely on HA in tissues such as the eye and cartilage. Hyaluronic acid has served as a critical building block to develop biomaterials with tissue regenerative properties.182 Modification of HA for bioadhesion through its abundant carboxyl conjugation sites has frequently been demonstrated.183 For instance, serotonin is a neurotransmitter released from platelets; it can activate platelets to enable secretion of blood-clotting factors such as platelet factor IV, factor V, von Willebrand factor, and fibrinogen. Serotonin can react with the functional groups present on the tissue surfaces and also act as a crosslinking component for gel formation.184 Serotonin conjugated to HA was shown to promote adhesion during gelation due to the free radicals generated that promote reaction with the underlying tissue substrate.184 This adhesion, however, is terminated upon completion of gelation (after 10 min) probably due to the full consumption of the oxidative intermediates. The adhesion-terminating character of the hydrogel after crosslinking was assigned to its anti-biofouling properties, which prevent unwanted and abnormal adhesion to the neighboring tissues. Catechol modification of HA is another approach to achieve bioadhesion. A two-component HA hydrogel involving HA-catechol mixed with HA modified with thiourea groups (HA-NCSN) was developed for healing gastric wounds.185 The pre-polymer solution was crosslinked using a NaIO4 spray. The thiourea groups in this formulation prevented auto-oxidation of catechol groups that cause adhesion loss. As opposed to HA-catechol bioadhesives, the HA-catechol/HA-NCSN composition led to stable adhesion in an acidic environment (pH ~2) making the gel a suitable candidate for sealing gastric wounds. In other examples,121,186 glycosaminoglycan HA was functionalized with a photoreactive functional group N-(2-aminoethyl)−4-(4-(hydroxymethyl)−2-methoxy-5-nitrosophenoxy) butanamide (NB), which generated aldehyde groups upon UV light irradiation. Aldehyde groups were able to form Schiff bases with the primary amine groups on the tissue surface for adhesion (Figure 9A). The NB-modified HA was reinforced with GelMA. High cohesion and adhesion led to burst pressure of up to 290 mmHg, higher than most commercial bioadhesives. The sealant rapidly stopped heavy bleeding from incisions in carotid arteries and the heart in vivo in a pig model (Figure 9B,C) due to its strong adhesion.

Figure 9. Different chemical modification strategies used to create gelatin-based bioadhesives.

(A) Chemical synthesis route for the development of highly adhesive and strong hydrogels based on modified hyaluronic acid (HA) and gelatin methacryloyl (GelMA) and its application in sealing (B) heart- and (C) arterial-related incisions. Reproduced with permission from ref 121. Copyright 2019, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. (D) Ex vivo evaluation of the methacryloyl-substituted tropoelastin (MeTro) sealant for sealing pig lung. (E) The sealing pressure was increased significantly using a MeTro hydrogel at 20 wt.% pre-polymer concentration. (F, G) Application of MeTro for sealing rat artery, and (H) the burst pressure suggesting the MeTro hydrogel is on the same order as a healthy artery. From ref 213. Reprinted with permission from AAAS. (I) Synthesis of the MeTro and (J) GelMA pre-polymers for application on the wound site. (J) MeTro/GelMA hydrogels in a crosslinked network. Reproduced with permission from ref 230. Copyright 2017, Elsevier.

Chitosan

Chitosan is obtained from one of the most abundant polysaccharides in nature (i.e., chitin from marine organisms such as shrimp, crab, etc.)187 and consists of β-(1→4)-linked N-acetyl-d-glucosamine homopolymers.188 Primary amine groups present on the chitosan backbone provide positive charges leading to its antimicrobial189 and hemostatic190 properties. Positive charges can be further enhanced by the quaternization of chitosan (QCS).191 The mixture of QCS with Fe3+-associated protocatechualdehydes, in a recent example, produced a strong antibacterial, photothermal, and bioadhesive hydrogel for the treatment of infected wounds.192 Note that both humoral and cell-mediated immune responses are associated with chitosan.193 Nevertheless, chitosan has shown promise in bioadhesives and has been used to treat bleeding and diabetic wounds.194,195