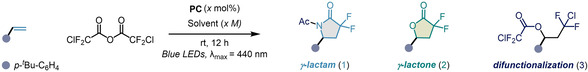

Table 1.

Reaction development and optimization.

|

| ||||||

|---|---|---|---|---|---|---|

|

Entry |

PC (1 mol%) |

Solvent |

Concentration [M] |

1 (%)[a] |

2 (%)[a] |

3 (%)[a] |

|

1 |

[Ir‐1] |

MeCN |

0.10 |

56 |

5 |

– |

|

2 |

[Ir‐1] |

MeCN |

0.03 |

92 (90)[e] |

2 |

– |

|

3 |

[Ru‐1] |

MeCN |

0.03 |

4 |

– |

– |

|

4 |

[Ir‐2] |

MeCN |

0.03 |

18 |

– |

– |

|

5 |

[Ir‐3] |

MeCN |

0.03 |

88 |

– |

– |

|

6 |

[Cu‐1] |

MeCN |

0.03 |

80 |

4 |

– |

|

7 |

[Ir‐1] |

MeCN[b] |

0.10 |

32 |

13 |

– |

|

8 [c] |

[Ir‐1] |

MeCN |

0.03 |

64 |

10 |

– |

|

9 |

[Ir‐1][d] |

MeCN |

0.03 |

83 |

6 |

– |

|

10 |

[Ir‐1] |

DCM |

0.03 |

– |

30 |

53 |

|

11 |

[Ir‐1] |

DMF |

0.03 |

– |

80 |

3 |

|

12 |

[Ir‐1] |

DMF |

0.17 |

– |

86 (81)[e] |

3 |

|

13 |

[Ir‐1] |

DMA |

0.03 |

– |

6 |

– |

|

14 |

[Ir‐1] |

CHCl3 |

0.03 |

– |

56 |

28 |

|

15 |

[Ir‐1] |

Dry Et2O |

0.03 |

– |

9 |

75 |

|

16 |

[Ir‐1] |

Toluene |

0.03 |

– |

16 |

76 |

|

17 |

[Ir‐1] |

Toluene |

0.17 |

– |

14 |

81 (75)[e] |

|

18 |

[Ir‐1] |

THF : CHCl3 (1 : 1) |

0.03 |

– |

44 |

14 |

|

| ||||||

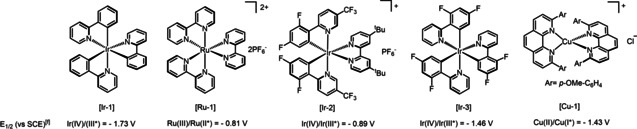

[a] General conditions: 4‐tert‐butylstyrene (0.5 mmol, 1 equiv), catalyst (1.0 mol %), and CDFAA (2 equiv), solvent (x M), 350 W blue LEDs, rt, 12 h. Yields of 1, 2, and 3 were determined by GC‐MS against an internal standard of n‐decane. [b] H2O (1 equiv) was added. [c] Reaction was performed with 2‐bromo‐2,2‐difluoroacetic anhydride. [d] 2.5 mol % of fac‐Ir(ppy)3. [e] Yields in parentheses represent isolated yields. [f] E 1/2 values were taken from refs. [5, 61, 62].