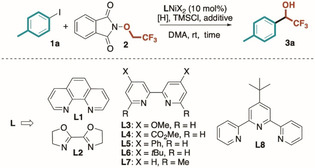

Table 1.

Optimization of the reaction conditions.

|

| ||||

|---|---|---|---|---|

|

Run[a] |

L |

[H]/additive |

Time [h] |

Yield 3 a [%][b] |

|

1 |

[Ni(L1)Cl2] |

Zn/– |

16 |

36 |

|

2 |

[Ni(L1)Cl2] |

Mn/– |

16 |

16 |

|

3 |

[Ni(L1)Cl2] |

TDAE/– |

16 |

0 |

|

4[c,d] |

[Ni(L2)Cl2] |

Zn/– |

16 |

0 |

|

5[c] |

[Ni(L3)Cl2] |

Zn/– |

16 |

55 |

|

6 |

[Ni(L3)Br2] |

Zn/– |

18 |

54 |

|

7[c,d] |

[Ni(L4)Cl2] |

Zn/– |

16 |

8 |

|

8 |

[Ni(L5)Cl2] |

Zn/– |

16 |

59 |

|

9[c] |

[Ni(L6)Cl2] |

Zn/– |

16 |

48 |

|

10[c,d] |

[Ni(L7)Cl2] |

Zn/– |

16 |

0 |

|

11[c] |

[Ni(L8)Cl2] |

Zn/– |

16 |

5 |

|

12 |

[Ni(L5)Cl2] |

Zn/NaI |

2 |

95 (88) |

|

13 |

[Ni(L5)Cl2] |

Zn/– |

2 |

30 |

|

14[e] |

[Ni(L5)Cl2] |

Zn/NaI |

2 |

60 |

[a] All reactions were carried out under N2 in dry DMA ([1 a]: 0.2 M, 2: 3 eq., [H]: 2 eq., TMSCl: 1 eq.; additive: 1 eq., cat: 10 mol%, unless otherwise specified). [b] Determined by 19F NMR on the reaction crude with an internal standard (CF3C6H5). In brackets, isolated yields after flash chromatography. [c] The catalytic complex was prepared in situ (L/NiCl2 ⋅ glyme: 15/10 mol%). [d] Dehalogenative homocoupling of 1 a was determined as the major product. [e] With reagent grade DMA and under air. [H]: reductant. NR: no reaction. TMSCl: chlorotrimethylsilane.